oem indigo powder indigo powder

Exploring the World of OEM Indigo Powder

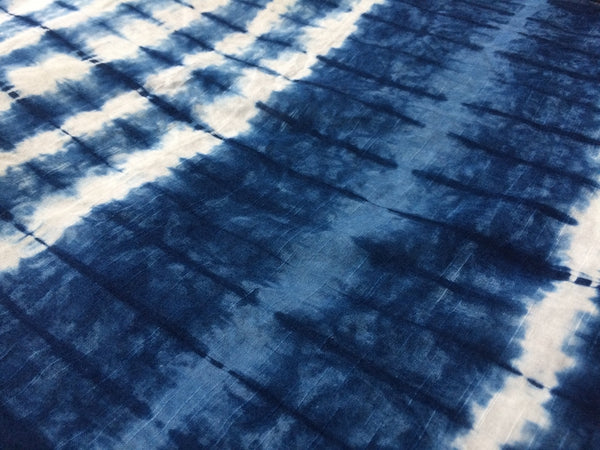

Indigo powder holds a significant place in the textile industry, primarily for its use as a dye. Historically, it originates from the leaves of the Indigofera plant, and its vibrant blue hue has been cherished for centuries. In recent years, however, the demand for indigo powder has evolved, especially in the realm of OEM (Original Equipment Manufacturer) production, where manufacturers create products tailored to the specifications of another company.

Exploring the World of OEM Indigo Powder

The global textile landscape is shifting toward sustainability, and this trend has impacted the production of indigo powder. Traditional methods of producing indigo dye can be resource-intensive and environmentally damaging. However, many OEM suppliers are now turning to eco-friendly extraction methods, such as fermentation, which drastically minimizes water usage and reduces chemical runoff. By working with these suppliers, companies can align their brands with sustainability initiatives, appealing to environmentally conscious consumers.

oem indigo powder indigo powder

Another intriguing aspect of OEM indigo powder is its use beyond textiles. With the rise of natural cosmetics and skincare products, indigo powder is being incorporated into formulations for its beneficial properties. It is known for its anti-inflammatory and antioxidant effects, making it an attractive ingredient in beauty solutions. By collaborating with OEM manufacturers specializing in both textiles and personal care, brands can diversify their product offerings, creating unique selling points that resonate with a broader audience.

Moreover, the global reach of OEM producers facilitates international trade and market expansion. Companies can tap into indigo powder manufacturing in different regions to take advantage of local resources and expertise. This not only enhances the supply chain but also encourages collaboration across cultures, leading to innovative product development.

In conclusion, the emergence of OEM indigo powder represents a fusion of tradition and modernity. The ability to customize, prioritize sustainability, and explore diverse applications has transformed this ancient dye into a contemporary product relevant in today's market. As industries continue to evolve, partnering with credible OEM suppliers will be crucial for businesses looking to remain competitive and innovative in their product offerings. By embracing these developments, companies can help shape a vibrant future for indigo powder in various sectors.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.