oem indigo grain

Exploring the World of OEM Indigo Grain A Unique Journey into Sustainable Practices

The term OEM stands for Original Equipment Manufacturer, a designation that has gained traction across various industries as sourcing and manufacturing processes become increasingly globalized. Coupled with indigo grain, this exploration delves into the intriguing intersection of sustainability, fashion, and ethical production practices.

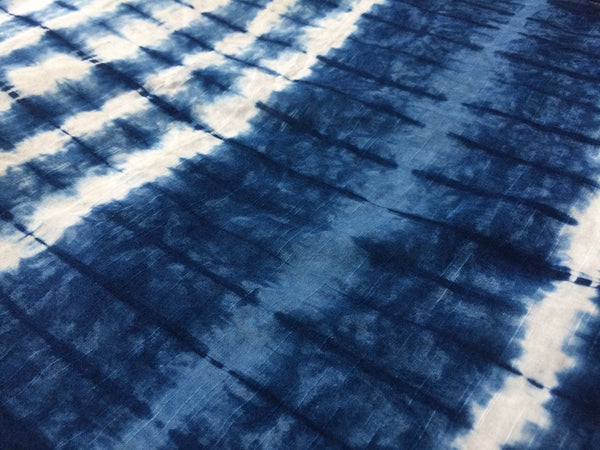

Indigo, renowned for its deep blue dye, has long been a symbol of artisanal craft, particularly in textile production. Traditionally sourced from the indigofera plant, indigo dye has been central to cultures worldwide, especially in regions like India and West Africa. The concept of grain, in this context, refers to the fine details and inherent quality characteristics imbued within the fabric's fibers, influencing not only its aesthetic appeal but also its environmental impact.

The Significance of OEM in the Indigo Market

As the global apparel industry grapples with the pressing need for sustainable practices, OEM partnerships have become pivotal. Through collaborations with textile manufacturers, fashion brands can leverage efficient supply chains and innovative production methods while maintaining high standards for quality and sustainability.

When it comes to indigo grain production, OEM partnerships allow brands to source materials that meet ethical criteria while ensuring consistency in quality. The importance of practicing responsible sourcing cannot be overstated, as consumers today are more conscious about where their products come from and how they are made.

By working with OEM partners committed to sustainable farming and production methods, brands can support eco-friendly practices that minimize environmental impact, such as reducing water usage and adopting organic farming techniques. This holistic approach contributes to a healthier ecosystem and provides reassurance to consumers that their clothing choices are aligned with their values.

The Art of Indigo Dyeing

Indigo dyeing is a meticulous art that requires expertise and a deep understanding of the dyeing process. From fermentation to oxidation, each step is essential to achieving the rich, vibrant colors consumers associate with indigo fabrics. The use of natural indigo dye presents an added sustainability bonus, as it is derived from renewable resources, in contrast with synthetic dyes that often involve harmful chemicals.

oem indigo grain

When employing OEM practices, the dyeing process can be optimized, ensuring factories are equipped with the latest technology while adhering to traditional methods that enhance the beauty and vitality of the fabric. Moreover, OEM collaborations can drive research and development into sustainable dyeing techniques that reduce water consumption and energy use, further promoting eco-friendly practices throughout the industry.

The Consumer Shift Towards Sustainable Fashion

The demand for sustainable fashion is on the rise, with consumers actively seeking brands that prioritize ethical manufacturing and sustainable sourcing. Market studies reveal that a growing number of millennials and Gen Z consumers are willing to pay a premium for sustainable products, viewing them as investments in a healthier planet.

This consumer shift presents an opportunity for brands to align their goals with the mission of conservation and environmental responsibility. By emphasizing the use of OEM indigo grain and promoting the story behind the fabric—from sourcing to manufacturing—brands can create a meaningful narrative that resonates with environmentally conscious consumers.

Challenges and Future Directions

While the benefits of OEM indigo grain production are clear, there are challenges that must be addressed. Transparency within the supply chain is essential, as consumers increasingly demand information about the origins of the products they purchase. Brands must strive to maintain open lines of communication with their OEM partners to create traceable systems that enhance accountability.

Additionally, investment in training and development is crucial, as many traditional artisans are facing challenges from industrialized production methods. Supporting local communities and artisans helps ensure that cultural heritage and skills are preserved while also fostering a sustainable future.

Conclusion

The journey of OEM indigo grain encapsulates the essence of sustainable fashion, blending tradition with innovation to create products that not only look good but also do good. As consumers and brands alike continue to prioritize sustainability, the partnership between OEMs and artisan producers is set to play a pivotal role in shaping the future of the fashion industry. Through conscious choices and collaborative efforts, we can foster a more sustainable planet, one indigo grain at a time.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.