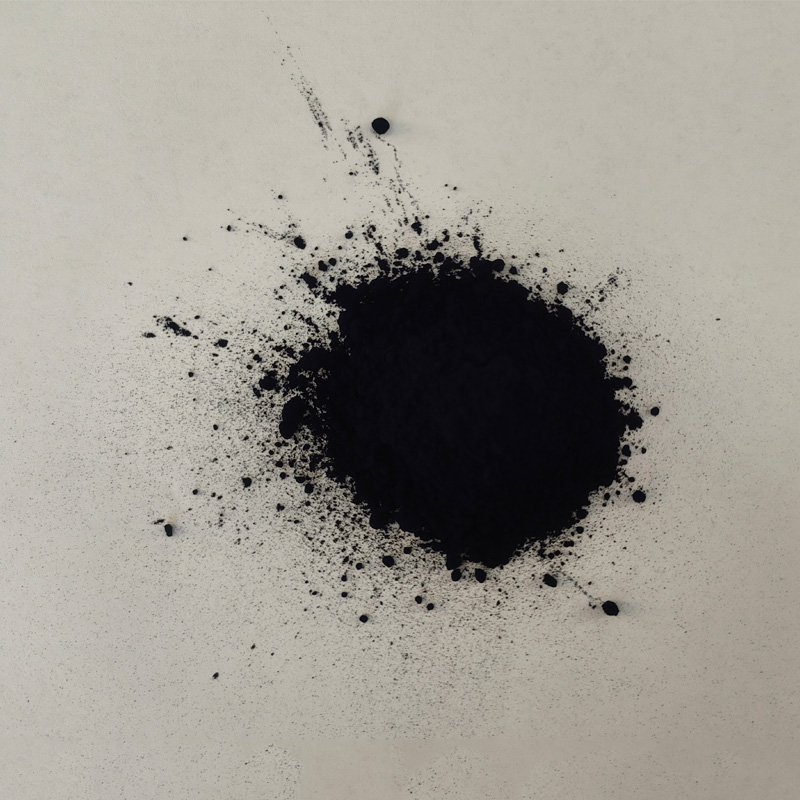

indian indigo powder factory

The Significance and Process of Indian Indigo Powder Production

Indigo dye, renowned for its deep blue hue and historical significance, has an intriguing journey that begins long before it reaches the shelves of modern markets. Among the various sources of indigo, Indian indigo powder stands out due to its rich heritage and unique production methods. This article explores the importance of indigo powder, the process of its production in India, and its relevance in today's world.

Historical Significance

Indigo has been used as a dye for over 6,000 years, with its earliest applications traced back to ancient Egypt and later in India, where it became a crucial part of textile production. The importance of indigo in India grew significantly during the colonial period when it was cultivated extensively for export. The vibrant blue color it produced was highly sought after in Europe, leading to the establishment of indigo plantations that often exploited local farmers. Despite its tumultuous history, indigo has maintained a special place in Indian culture, symbolizing craftsmanship and artistic expression.

The Indigo Plant

The primary source of indigo is the indigofera plant, particularly Indigofera tinctoria, which thrives in tropical regions. This plant contains a compound called indican, which is converted into indigo dye through fermentation. The growing popularity of plant-based dyes, owing to increasing awareness about sustainable practices and the adverse effects of synthetic dyes, has revived interest in indigo cultivation. Farmers are now turning back to traditional methods, promoting biodiversity and sustainable agriculture.

The Production Process

indian indigo powder factory

The production of indigo powder involves several meticulous steps. Firstly, farmers cultivate the indigo plants and harvest the leaves once they are mature. The leaves are collected and submerged in water for fermentation, which is a critical process that breaks down indican into indigo. During this fermentation, the leaves are stirred continuously to promote the oxidation process, leading to the formation of blue indigo crystals.

After fermentation, the liquid is drained off, allowing the indigo to settle. The settled indigo mass is then washed and processed further to remove any impurities. Once dried, the indigo is ground into a fine powder, ready for use in dyeing fabrics, arts, and crafts.

Cultural Revival and Modern Applications

In recent years, there has been a resurgence of interest in traditional methods of indigo production, driven by a growing market for sustainable and organic products. Artisans and small-scale manufacturers have embraced eco-friendly practices, promoting indigo as a natural dye alternative. This shift comes not only from a desire for sustainability but also as a means to preserve cultural heritage.

Indigo powder is now utilized in various applications beyond textiles. It is used in cosmetics for its natural coloring properties and is increasingly being sought after in the culinary world, where it adds a striking blue hue to dishes. The shift towards natural products has also led to greater demand for handmade textiles and artisanal products, allowing local artisans to thrive.

Conclusion

Indian indigo powder represents more than just a coloring agent; it embodies a rich history, a sustainable future, and the artistry of Indian craftsmanship. As the world moves toward more eco-friendly practices, the revival of indigo production not only helps preserve traditional knowledge but also supports local economies and promotes biodiversity. The journey of indigo, from the fields of India to modern applications, serves as a reminder of the intricate connection between culture, sustainability, and innovation. With its deep roots in history and its vibrant presence in the contemporary market, Indian indigo powder is poised to continue making its mark in the world.

-

Sulphur Black Dyes in Daily Use

NewsMay.07,2025

-

Indigo Dyeing for Daily Life

NewsMay.07,2025

-

Indigo Dye Production and Its Growing Demand

NewsMay.07,2025

-

Color That Lasts

NewsMay.07,2025

-

Bromo Indigo for Modern Use

NewsMay.07,2025

-

Blue From Nature

NewsMay.07,2025

-

The Timeless Color in Fashion and Textiles

NewsApr.10,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.