Production of Sulphur Black BR in Textile Manufacturing Industry

Understanding Sulphur Black BR Production A Deep Dive into the Factory Process

Sulphur Black BR is a prominent synthetic dye widely used in the textile industry for achieving deep black shades, especially on cotton and other cellulose fibers. The production process of this dye occurs in specialized factories equipped with advanced technology and stringent safety measures. In this article, we’ll explore the intricacies of the Sulphur Black BR manufacturing process, from raw material selection to the end product, while highlighting its significance in the world of dyes and pigments.

Raw Material Selection

The production of Sulphur Black BR begins with the careful selection of raw materials. Primarily, the key ingredients include sodium sulphide, sodium hydroxide, and various aromatic compounds. These materials are essential for the chemical reactions that will ultimately lead to the formation of the dye. The quality of the raw materials directly influences the final product's color intensity, fastness properties, and overall performance.

The Synthesis Process

Once the raw materials are procured, they undergo a synthesis process in large reaction vessels. Initially, sodium sulphide is mixed with the aromatic compounds, which serve as the building blocks for the dye molecule. This mixture undergoes a controlled reaction involving heating and stirring to ensure that the compounds interact appropriately.

During this stage, it is crucial to maintain optimal temperature and pH levels as they significantly impact the yield and quality of the dye. Advanced monitoring systems are employed to provide real-time data, allowing operators to make necessary adjustments.

Precipitation and Filtration

After the synthesis process is complete, Sulphur Black BR is typically in a soluble form. The next step involves precipitating the dye from the liquid mixture. This is achieved by adjusting the pH and introducing specific agents that cause the dye to form solid particles. Once the dye has precipitated, it is then filtered to separate the solid Sulphur Black BR from the remaining liquid.

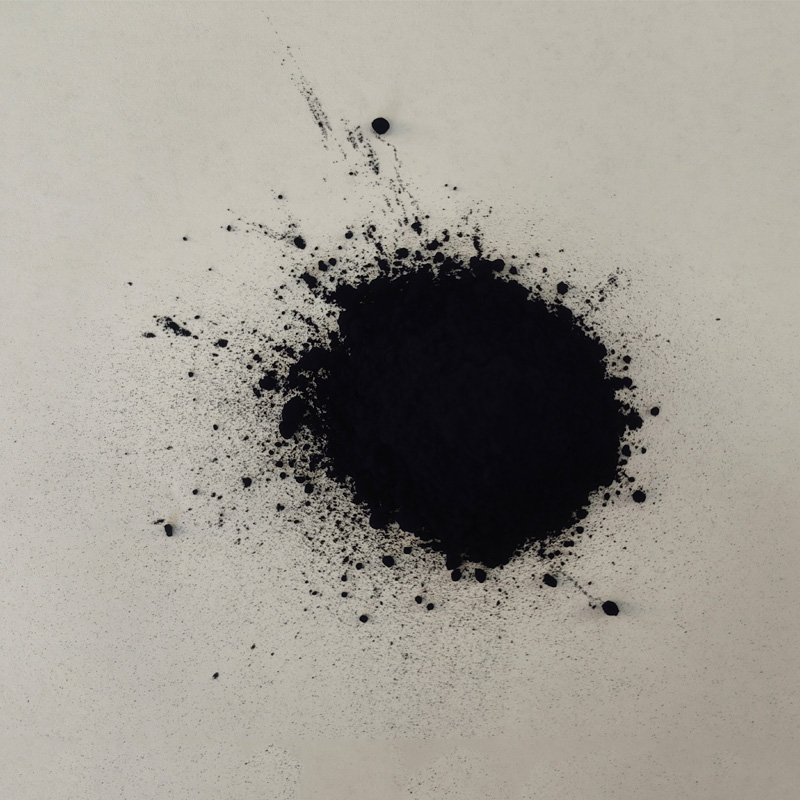

sulphur black br factory

The filtration process removes impurities and unreacted raw materials, ensuring that the final product is of high purity. This step is critical, as any residual contaminants could affect the dye's performance during application.

Drying and Milling

Following filtration, the wet Sulphur Black BR is carefully dried. This is typically done using specialized drying equipment that controls temperature and humidity levels to avoid degradation of the dye. The dried product is then milled to achieve the desired particle size for ease of handling and application.

Achieving the correct particle size is essential for uniform dispersion of the dye in textile production processes. Too coarse of a particle size may lead to uneven dyeing, while too fine can clump together, impeding proper integration with fibers.

Quality Control

Quality control is integral throughout the manufacturing process. Samples of Sulphur Black BR are taken at various stages and subjected to rigorous testing for color strength, fastness properties (such as light, wash, and rub fastness), and solubility. These tests ensure that the dye consistently meets industry standards and customer expectations.

Moreover, the factory adheres to environmental regulations and safety standards, incorporating processes to minimize waste and emissions. Responsible manufacturing practices reflect the industry's growing commitment to sustainable production methods.

Conclusion

The production of Sulphur Black BR is a complex, multi-step process that combines chemistry, engineering, and quality assurance to create a product that is essential in the textile industry. Understanding this process highlights the sophistication involved in dye manufacturing, emphasizing the importance of each stage in achieving a high-quality, reliable product. As demand for sustainable practices in manufacturing grows, factories producing Sulphur Black BR are continually evolving to meet these challenges while maintaining the quality that their customers depend on. The careful balance of science, technology, and environmental responsibility is crucial as the industry looks to the future of dye production.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.