light indigo color company

Trustworthiness is crucial when choosing a partner for indigo dye production. The reputation of an ODM plant is built on reliability and quality consistency. This assurance enables companies to establish trust with their end consumers, who demand transparency and ethical production methods. Working with an ODM plant allows businesses to prominently display certifications related to fair trade, organic products, and environmental stewardship. This transparency and commitment to ethical practices foster consumer trust, which is invaluable in building brand reputation in the competitive textile market. Moreover, an ODM facility can enhance a business’s adaptability and market agility. By partnering with a plant experienced in indigo dye production, companies can better respond to market trends and consumer demand. This flexibility is achieved through scalable operations, allowing businesses to adjust production volume in response to market fluctuations without compromising on quality or delivery timelines. This is particularly advantageous in the fast-paced fashion industry, where trends can shift rapidly. ODM plants also reduce the logistical burdens associated with dye production. By outsourcing the manufacturing process, companies can focus their efforts on core business areas such as design innovation, marketing, and retail distribution. This strategic allocation of resources enables more efficient business operations and facilitates growth across other verticals. The decision to collaborate with an ODM plant for indigo dye is more than a strategic move—it's a commitment to quality, sustainability, and innovation. It exemplifies a proactive approach to business operations, positioning companies to meet the needs of a discerning global market while safeguarding environmental heritage and promoting ethical practices. As the textile industry evolves, those who embrace such strategic partnerships will likely emerge as leaders in the market, distinguished by their ability to deliver unparalleled product excellence and operational integrity.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

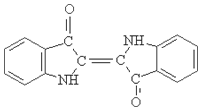

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.