Exploring the Unique Shades of Indigo Powder for OEM Applications

The OEM Colour of Indigo Powder A Deep Dive into its Significance and Applications

Indigo powder, derived from the leaves of the Indigofera plant, has a rich history and is renowned for its striking deep blue color. With roots tracing back thousands of years, this natural dye has been used in various cultures around the globe, providing not just color but also a unique cultural significance. The term OEM stands for Original Equipment Manufacturer, often associated with industrial processes and branding. In the context of indigo powder, understanding the OEM colour offers insights into its application in various industries, from textiles to cosmetics.

The Historical Context of Indigo

Indigo dyeing techniques originated in ancient civilizations, with the earliest recorded use dating back to ancient Egypt. The Egyptians utilized indigo for mummification and textiles. Meanwhile, in Asia, particularly in India and Japan, indigo became a symbol of social status and cultural identity. Throughout the centuries, the popularity of indigo grew, especially during the Colonial Era, when European powers recognized its economic potential and established indigo plantations in colonies.

The Chemistry Behind Indigo Powder

The vibrant blue of indigo powder is due to the presence of indigotin, a complex organic compound. When the leaves of the Indigofera plant are fermented, the indigotin is released and can be processed into a fine powder. This powder can then be used in various applications but must first undergo specific treatment processes to maintain its quality and hue.

In the dyeing process, indigo powder requires a reducing agent to convert insoluble indigotin into a soluble form, allowing it to bond to the fibers of textiles. Once the dyeing process is complete, exposure to oxygen restores the original blue pigment, completing this fascinating transformation.

The Role of OEM in Indigo Powder Production

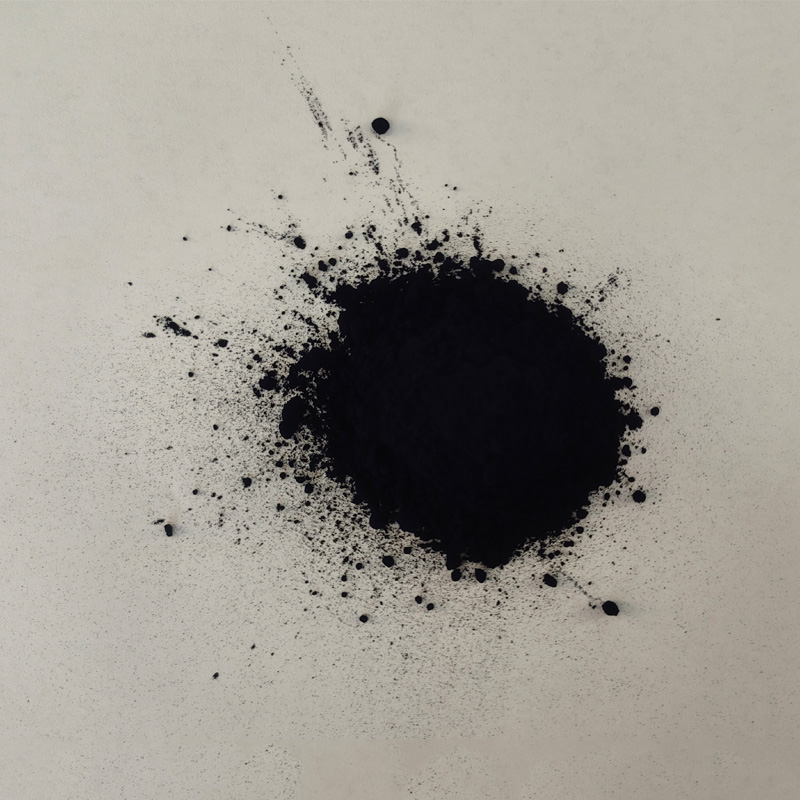

oem colour of indigo powder

The term OEM is crucial in the manufacturing and distribution of indigo powder. Companies that specialize in creating indigo products may collaborate with OEM providers to gain consistent quality and ensure that the indigo powder meets specific standards. This partnership is vital for businesses seeking to maintain product integrity, particularly in the fashion and textile industries.

In addition, OEM suppliers offer customization options to suit diverse market needs. This adaptability is essential as consumer preferences shift toward organic and natural products. Therefore, the ability to provide indigo powder that meets the OEM color specifications ensures that companies can cater to niche markets, including eco-friendly and sustainable fashion.

Applications of Indigo Powder

Indigo powder's applications are extensive. The most obvious use is in textiles, where it remains one of the most popular dyes for denim and other fabrics. The iconic blue jeans we wear today owe much to this ancient dye, which provides not only color but also a sense of heritage and craftsmanship.

Beyond textiles, indigo powder is also finding its way into the world of cosmetics. Its natural coloring properties have made it a sought-after ingredient for various beauty products. From hair dyes to natural eyeshadows, indigo powder offers a vibrant, synthetic-free alternative that appeals to consumers seeking clean beauty options.

Furthermore, indigo powder's use extends to the realm of health and wellness. In traditional medicine, it is believed to possess various therapeutic properties, such as anti-inflammatory and antimicrobial effects. While scientific research is ongoing, the applications of indigo in herbal remedies showcase its wide-ranging significance.

Conclusion

The OEM colour of indigo powder encompasses much more than a simple hue; it represents a journey through history, culture, and innovation. With its significant role in textiles, cosmetics, and health, indigo powder continues to thrive and adapt in a modern context. As consumers increasingly seek natural and sustainable options, the importance of quality indigo powder, provided through OEM partnerships, will undoubtedly grow. Embracing this age-old dye and its myriad applications is not just about color; it is about celebrating a rich cultural heritage while moving towards a more sustainable future.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.