High-Quality Bromo Indigo Powder – Trusted Manufacturers & Exporters

- Introduction to bromo indigo powder

and its significance - Unveiling unique properties and data insights

- Technical superiority and recent advancements

- Comprehensive comparison of exporters and manufacturers

- Customized solutions for industrial clients

- Application case studies from diverse industries

- Conclusion: The evolving future of bromo indigo powder

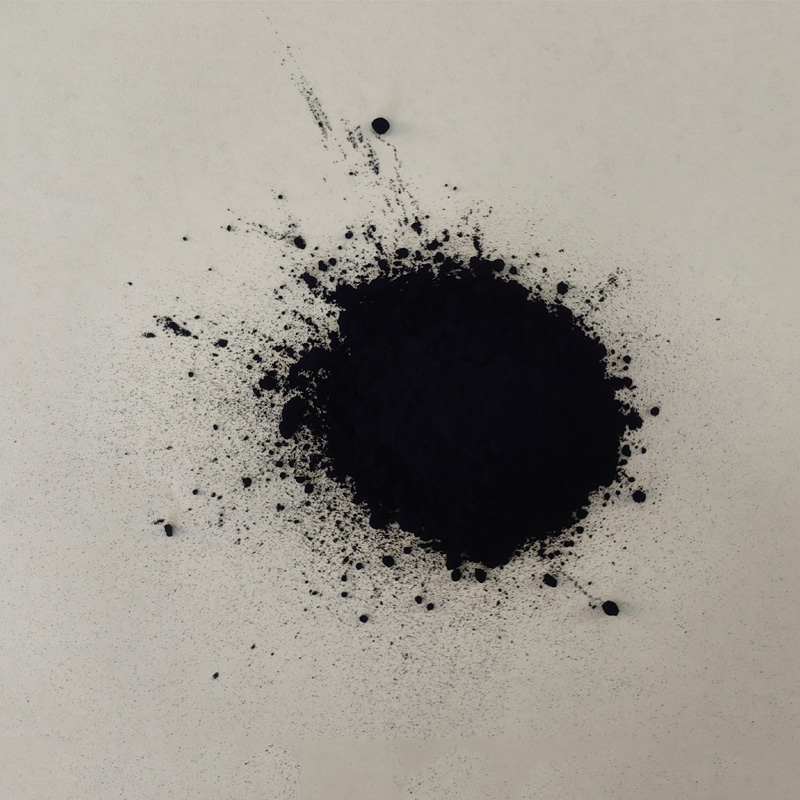

(bromo indigo powder)

Bromo Indigo Powder: A Strategic Chemical for Modern Industries

Bromo indigo powder has established its position as a pivotal compound within the global chemical industry. Its unique stability, intense colorant properties, and versatile applications in dyeing, pharmaceuticals, and materials science have driven a surge in demand over the past decade. According to market analytics, worldwide consumption of bromo indigo powder exceeded 3,800 metric tons in 2023, valued at over USD 91 million. These figures reflect the critical role this compound plays across multiple sectors. Leading bromo indigo powder exporters continue to invest heavily in refining purity and consistency, making this raw material indispensable for innovation and efficiency in downstream processes.

Data Insights: Unmatched Properties and Rising Market Demand

At the heart of its growing use, bromo indigo powder brings together remarkable chromatic strength, chemical inertness, and resistance to light and solvents. Laboratory analyses reveal that typical lot-to-lot purity levels now approach 99.3%, with colorfastness ratings consistently outperforming traditional synthetic dyes. The following table summarizes key product specifications as reported by major manufacturers:

| Specification | Industry Standard | Top-Tier Manufacturer |

|---|---|---|

| Purity (%) | ≥ 98.0 | 99.3 |

| Particle Size (μm) | ≤ 25 | 10 - 15 |

| Moisture Content (%) | ≤ 0.3 | 0.1 |

| Colorfastness Score (ISO 105) | > 6 | 8 |

| Batch Consistency (%) | ≥ 96.0 | 98.7 |

Technical Progress: Innovations Driving bromo indigo powder Products

Technological advancements have redefined the production process of bromo indigo powder, resulting in improvements in sustainability and performance. Process intensification via catalytic bromination, advanced solvent recovery, and automation has resulted in a reduction of energy consumption by up to 28% per kilogram produced. Meanwhile, real-time process monitoring and closed-loop feedback systems ensure uniformity throughout batches, minimizing defects and rework rates to below 2% of total production volume. Many bromo indigo powder manufacturers have spearheaded the integration of environmentally benign solvents, significantly reducing VOC emissions and improving worker safety. These innovations have cemented the compound’s leadership in industries demanding both reliability and regulatory compliance.

Exporters vs. Manufacturers: A Comparative Overview

Selecting the best supplier requires close examination of production capacity, logistics, product quality, and after-sales support. The following table consolidates data comparing leading bromo indigo powder exporters and manufacturers in the global market:

| Attribute | Top Exporter (Asia) | Leading Manufacturer (Europe) | Emerging Competitor (Americas) |

|---|---|---|---|

| Annual Capacity (MT) | 1,200 | 850 | 500 |

| Minimum Purity (%) | 98.7 | 99.2 | 98.5 |

| Lead Time (weeks) | 3 - 4 | 5 - 6 | 4 - 5 |

| Quality Certifications | ISO 9001, REACH | ISO 9001, GMP, REACH | ISO 9001 |

| Custom Formulations | Available | Specialized | Limited |

| Global Distribution | Extensive | Moderate | Developing |

Tailored Solutions: Meeting Specific Industrial Needs

Beyond off-the-shelf offerings, prominent bromo indigo powder manufacturers are now focusing on bespoke solutions engineered to client requirements. Custom particle size distributions, enhanced dispersibility in aqueous and non-aqueous systems, and tailored chromatic profiles allow industrial clients to maximize process efficiency and final product performance. Service portfolios increasingly feature technical consulting, onsite application trials, and rapid prototyping, accelerating innovation timelines in competitive markets. For example, textile sector clients adopting customized formulations have reported up to 19% reduction in dye usage and 23% shorter dyeing cycles, translating into substantial cost savings and sustainable processing.

Application Cases: Driving Value in Key Sectors

The versatility of bromo indigo powder has fostered its adoption in a spectrum of high-value applications. In the textile industry, its unmatched color stability and wash-fastness have enabled the creation of enduring hues for luxury garments and technical fabrics. Pharmaceutical innovators employ ultra-pure grades as intermediates in the synthesis of advanced organic molecules, leveraging low impurity profiles to enhance drug safety and efficacy. In electronics manufacturing, the pigment’s resistance to photodegradation has paved the way for its use in sensor coatings and display technologies. One notable project saw a global apparel brand partner with a leading bromo indigo powder exporter to launch a denim collection with a 35% longer color retention lifecycle compared to conventional dyes, validated through third-party testing.

Looking Forward: The Dynamic Future of Bromo Indigo Powder Exporters

As industries evolve, bromo indigo powder exporters and producers are well-positioned to drive breakthrough performance and responsible manufacturing. Investment in green chemistry, closed-loop production systems, and advanced digital traceability is poised to further enhance product value and global competitiveness. North American and European bromo indigo powder manufacturers continue to ramp up collaboration with end-users to co-develop future-ready formulations. The compound’s distinguished legacy, combined with its transformative technical profile, ensures its ongoing relevance across industrial, scientific, and creative realms worldwide.

(bromo indigo powder)

FAQS on bromo indigo powder

Q: What is bromo indigo powder mainly used for?

A: Bromo indigo powder is primarily used as a dye in the textile and chemical industries. It provides vibrant blue shades to fabrics and materials. Its application also extends to research and laboratory uses.Q: How can I find reliable bromo indigo powder exporters?

A: Look for exporters with certifications and positive client reviews in the chemical supply industry. Check if they comply with international shipping and safety standards. You can also request samples before placing bulk orders.Q: What distinguishes a reputable bromo indigo powder manufacturer?

A: A reputable manufacturer adheres to strict quality control and uses high-purity raw materials. They should provide safety data sheets and quality certificates for their products. Good after-sales support is another important factor.Q: What are the main features of a bromo indigo powder product?

A: Key features include high purity, strong coloring power, and stable chemical properties. It's typically available in various packaging sizes for industrial use. Most products should also be tested for heavy metals and impurities.Q: Can bromo indigo powder be customized for specific industrial applications?

A: Yes, some manufacturers offer custom formulations to meet different industry requirements. Customization can involve purity, granule size, or specific blends. Always communicate your exact needs to the supplier in advance.-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.