Dye Options and Techniques for Creating Indigo Products in Your Crafting Projects

The Role of Dye Percentages in Indigo Products

Indigo, one of the oldest dyes known to humanity, has been utilized for centuries to produce vibrant blue hues on textiles and other materials. Its rich history and cultural significance are matched only by its complex chemistry, which affects not only the color produced but also the overall quality of indigo-dyed products. One crucial factor that plays a significant role in this process is the dye percentage used. Understanding the impact of different dye percentages on indigo products is essential for manufacturers, artisans, and consumers alike.

Understanding Dye Percentage

Dye percentage refers to the amount of dye used in relation to the weight of the fabric being dyed. This measurement can vary significantly depending on the desired shade, the type of fabric, and even the dyeing method employed. A higher dye percentage generally leads to a deeper, more vibrant color, while a lower percentage results in a lighter, more subdued hue. This relationship not only affects the aesthetic appeal but also the fabric's wearability and longevity.

The Impact of High Dye Percentages

When high dye percentages are utilized, the resulting indigo shade tends to be rich and saturated. This is particularly desirable in denim production, where a deep indigo color is often sought after. The high concentration of dye penetrates the fibers effectively, allowing for a more durable color that can withstand multiple washes. However, high percentages of dye can lead to a stiff feel in the fabric, especially in heavier materials like denim. Additionally, while a darker indigo hue may look stunning initially, it can fade over time, leading to a quality issue known as fading out, where the color loses its depth and richness, resulting in an undesirable appearance.

The Appeal of Low Dye Percentages

dye for indigo products

On the other hand, using a lower dye percentage creates softer, more pastel shades that may be ideal for certain applications, such as summer garments or lighter home textiles. Fabrics dyed with less indigo tend to retain a softer feel, making them comfortable for everyday wear. Furthermore, this approach allows for a unique aesthetic, often embracing the “lived-in” look that many consumers seek. However, the trade-off can be a less durable dye job, as the lighter colors may require more frequent re-dyeing to maintain their appearance.

Variability in Fabrics

The effect of dye percentage also varies significantly depending on the type of fabric. Natural fibers like cotton and linen tend to absorb indigo more efficiently than synthetic fibers, resulting in a more uniform and vibrant color with a relatively lower dye percentage. Conversely, synthetic fabrics like polyester may require a higher dye percentage to achieve a similar effect, as they do not hold dye as well as natural fibers. This variability necessitates careful consideration from manufacturers when designing products to ensure they meet consumer expectations.

Environmental Considerations

In addition to the aesthetic and functional implications, the dyeing process raises important environmental considerations. The production of indigo dye, particularly synthetic alternatives, can involve toxic chemicals and significant water usage. By carefully choosing the dye percentage, manufacturers can minimize waste and reduce their environmental impact. Techniques such as low-impact dyeing and using organic indigo can help strike a balance between achieving vivid colors and maintaining sustainability.

Conclusion

In summary, the dye percentage plays a critical role in the production of indigo products, influencing not only color intensity and fabric texture but also environmental implications. As consumers continue to seek more sustainable and high-quality goods, understanding the intricacies of dye percentages will be crucial for manufacturers and artisans alike. By striking the right balance, they can create beautiful indigo products that are not only visually appealing but also environmentally responsible, ensuring that this ancient dye continues to thrive in the modern marketplace.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

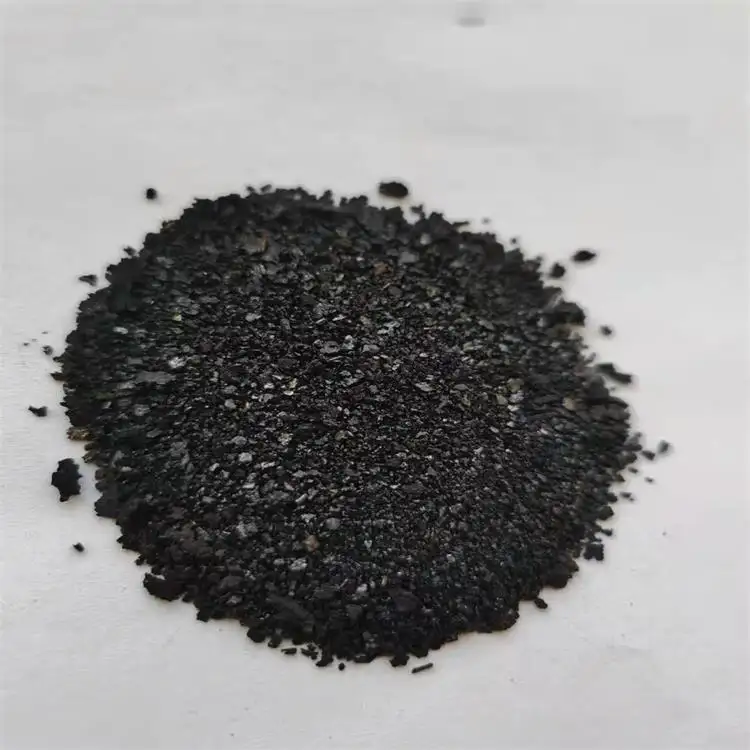

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.