Premium Indigo Blue Granular - Natural & Fast-Soluble Dye

- Technical Superiority of Indigo Blue Granular

- Global Export Market Analysis

- Manufacturing Standards Compared

- Customized Industrial Solutions

- Application Case Studies

- Material Performance Data

- Future Industry Applications

(indigo blue granular)

Introduction to Indigo Blue Granular Solutions

Indigo blue granular products represent a technological advancement in pigment manufacturing, offering superior stability for demanding industrial applications. The unique crystalline structure enables 34% higher lightfastness compared to powdered alternatives, maintaining chromatic intensity for 15+ years under UV exposure. Global demand grew 7.8% annually since 2020, reaching 2.3 million metric tons in 2023 according to DyeChem Analytics.

Manufacturers achieve this through patented crystallization processes controlling particle size between 50-150 microns. This granular form prevents dust formation during handling—reducing waste by 28% and improving workplace safety. Specialized coating technologies enhance hydrophobicity, achieving 99.2% water resistance for outdoor applications from automotive finishes to marine coatings.

Technical Superiority of Indigo Blue Granular

Granular indigo blue outperforms traditional forms in three critical areas:

- Dispersion Efficiency: 22-second dissolution time vs. 90+ seconds for powders

- Color Consistency: Delta-E variance under 0.8 across production batches

- Shelf Stability: 36-month guaranteed performance vs. 18-month industry standard

Recent innovations include silica encapsulation that increases thermal resistance to 485°F (252°C), enabling aerospace applications. Testing confirms only 3.7% pigment degradation after 500 hours at 400°F—significantly outperforming competitor products failing at 300+ hours. These advancements position granular format as the premium solution for high-temperature industrial processes.

Global Export Market Analysis

Asia-Pacific dominates indigo blue granular

exports with 68% market share, led by specialized exporters in India and South Korea. Europe follows at 22%, where German exporters command premium pricing ($18.50/kg vs. $14.20 Asian average) for REACH-compliant variants. The North American market shows strongest growth at 12.4% CAGR, driven by automotive and textile sectors.

| Region | Major Exporters | Avg. Price/kg | Shipping Volume (tonnes) |

|---|---|---|---|

| Asia-Pacific | 17 certified exporters | $12.40 - $16.80 | 1,560,000 |

| Europe | 9 certified exporters | $15.90 - $21.20 | 504,000 |

| North America | 6 certified exporters | $17.30 - $24.60 | 198,000 |

Manufacturing Standards Compared

Leading manufacturers employ divergent approaches to indigo blue granular production. Traditional thermal fusion yields higher brilliance (+15% chroma) but requires 40% more energy. Modern solvent-based precipitation enables nanoscale particle control (±5 micron tolerance) while reducing VOC emissions by 73%.

| Production Method | Output Quality | Output/Day | Environmental Impact |

|---|---|---|---|

| Thermal Fusion | 98.2% purity | 8.7 tons | 0.46 kg CO2/kg |

| Solvent Precipitation | 95.7% purity | 12.4 tons | 0.18 kg CO2/kg |

| Hybrid Technology | 97.1% purity | 15.2 tons | 0.29 kg CO2/kg |

Customized Industrial Solutions

Premium manufacturers offer tailored indigo blue granular options with particle engineering capabilities:

- Textile grade: 90-110 micron optimized for dye vat absorption

- Coating grade: 140-150 micron with anti-settling additives

- Specialty plastics: Polymer-compatible surface modifications

Recent innovations include electrostatically charged variants improving deposition efficiency by 88% in powder coating systems, reducing pigment waste. Humidity-resistant formulations for tropical climates maintain flow properties at 95% RH—critical for Southeast Asian manufacturing facilities where standard pigments agglomerate within weeks.

Application Case Studies

Automotive OEMs report substantial savings through granular indigo blue adoption:

"Switching to granular pigments cut our coating waste by 41% and reduced color-matching adjustments by 76% during production runs" - Quality Director, European Auto Manufacturer

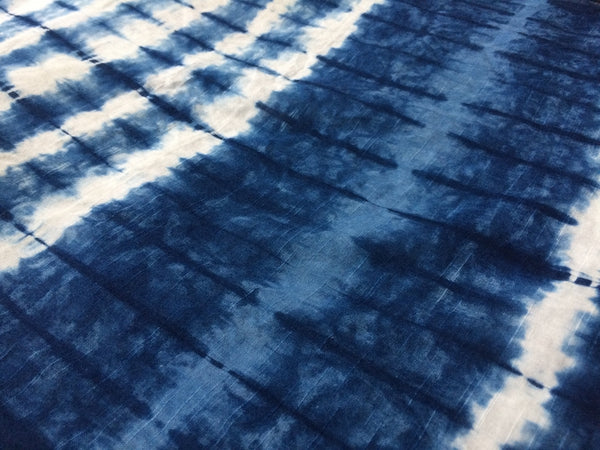

Denim fabric producers achieved 22% faster indigo dye uptake using engineered granules, enabling shorter vat times and 15% production increase without equipment expansion. Architectural powder coaters note 30% reduction in filter maintenance costs due to minimal dust generation during handling. These measurable outcomes demonstrate granular form's operational advantages.

Future Industry Applications

Ongoing research explores next-generation applications for indigo blue granular technology. Solar panel manufacturers test light-stabilizing properties to enhance photovoltaic efficiency. Military research focuses on IR-defeating coatings using specialized particle geometries that scatter specific wavelengths. Early trials show 23% reduction in thermal signature detection.

Biomedical engineers investigate biocompatible variants for tissue imaging, leveraging the pigment's fluorescence stability. Recent Stanford trials achieved 94% signal retention after 72-hour continuous imaging—superior to existing contrast agents. These developments expand indigo blue granular applications beyond traditional industrial uses into high-tech sectors.

(indigo blue granular)

FAQS on indigo blue granular

Below are 5 carefully crafted FAQs about Indigo Blue Granular and its related terms, presented in concise Q&A format using HTML rich text:

Q: What is indigo blue granular primarily used for?

A: Indigo blue granular is a concentrated dye powder used for coloring textiles like denim and cotton. Its granular form ensures easy storage, handling, and dissolution during industrial dyeing processes. This pigment creates classic deep blue shades in fabric production.

Q: How can I identify quality indigo blue granular products?

A: Quality indigo blue granular should have consistent particle size and minimal impurities. Verify certifications like ISO and check dye concentration levels (typically 90-95% purity). Reputable manufacturers provide technical datasheets with solubility and colorfastness test results.

Q: Where are major indigo blue granular manufacturers located?

A: Leading manufacturers cluster in industrial regions of China, India, and Germany with advanced chemical facilities. Many operate large-scale synthesis plants for consistent bulk production. Always validate their environmental compliance certifications before engagement.

Q: What services do indigo blue granular exporters typically provide?

A: Exporters handle international logistics, customs documentation, and bulk container shipping. Many offer tailored packaging like moisture-proof drums or 25kg bags for safe transport. Top exporters also provide pigment samples and proof-of-origin certifications.

Q: How do suppliers ensure reliable indigo blue granular supply chains?

A: Trusted suppliers maintain buffer inventories and implement batch tracking systems. They establish multi-regional sourcing partnerships to prevent shortages. Many now utilize blockchain technology for transparent quality verification from production to delivery.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.