oem indigo dye for clothes

Exploring the World of OEM Indigo Dye for Clothes

Indigo dye has a rich history that dates back thousands of years, having been utilized in various cultures around the globe. As the demand for sustainable and vibrant textile solutions increases, OEM (Original Equipment Manufacturer) indigo dye has emerged as a game-changing option for clothing manufacturers. This article delves into the significance of OEM indigo dye and its impact on the fashion industry, emphasizing its benefits, production processes, and environmental considerations.

The Significance of Indigo Dye

Indigo dye, derived from the Indigofera plant, is renowned for its deep blue color and has traditionally been used in dyeing fabrics, including denim, cotton, and silk. Its significance is deeply embedded in fashion history; for instance, blue jeans, a staple in modern wardrobes, owe their characteristic hue to indigo. However, the demand for this dye has led to a surge in synthetic alternatives, prompting a need for a return to natural and eco-friendly options.

OEM indigo dye plays a crucial role in this context. By partnering with manufacturers who specialize in indigo production, clothing brands can ensure the consistent quality and availability of dye while also adhering to sustainable practices. This approach allows brands to maintain their unique identity while minimizing environmental impact.

Benefits of Using OEM Indigo Dye

1. Quality Assurance Working with OEM suppliers means that clothing manufacturers can rely on a standardized quality of indigo dye. This consistency is vital for brands that prioritize durability and color fastness in their products.

2. Sustainability Many OEM indigo dye manufacturers are now using eco-friendly processes to produce this dye, significantly reducing water usage and chemical pollutants. For instance, some are employing fermentation methods to extract indigo from plants, promoting a circular economy.

oem indigo dye for clothes

3. Cost-Effectiveness By utilizing OEM services, clothing brands can achieve economies of scale. This often translates into lower costs per unit, which can be reinvested into other areas of the business, thereby enhancing overall profitability.

4. Customization OEM providers can offer tailored solutions, allowing brands to create unique shades or formulations of indigo dye that align with their specific aesthetic requirements and brand identity.

The Production Process

The production of OEM indigo dye typically involves several stages, including cultivation, harvesting, and extraction. The indigo plants are cultivated sustainably, ensuring that farming practices do not deplete local ecosystems. After harvesting, the leaves undergo a fermentation process, which helps to convert indican into indigo dye, ultimately yielding a product that can be used in textile dyeing.

Once the indigo dye is produced, it is often prepared in concentrated forms for ease of transportation and use in manufacturing. Clothing brands can then purchase these concentrates to create their signature styles, ensuring that their garments have the vibrant hues that consumers desire.

Environmental Considerations

As the fashion industry increasingly turns its attention to sustainable practices, the choice to use OEM indigo dye is becoming more appealing. Manufacturers who opt for this natural dye source are not only responsible stewards of the environment but also cater to the growing consumer demand for eco-friendly products. This shift is essential for mitigating the negative impacts of conventional dye processes, which often involve hazardous chemicals and excessive water consumption.

In conclusion, OEM indigo dye for clothes represents a harmonious blend of tradition, sustainability, and innovation. By opting for this natural dye, clothing brands can enhance their product offerings while supporting environmentally responsible practices. As the fashion industry continues to evolve, OEM indigo dye stands out as a beacon of hope in the pursuit of a more sustainable future.

-

Thermal Stability Analysis of Bromo Indigo Pigments

NewsJun.06,2025

-

Sulphur Black Dye Oxidation Process Optimization

NewsJun.06,2025

-

Lightfastness Testing of Bromo Indigo Dyed Denim

NewsJun.06,2025

-

Granule Size Distribution and Jeans Color Uniformity

NewsJun.06,2025

-

Gradient Dyeing Methods with Indigo Blue Granules

NewsJun.06,2025

-

Dyeing Temperature Effects on Sulphur Black Color Fastness

NewsJun.06,2025

-

Sulphur Black Dyes in Daily Use

NewsMay.07,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

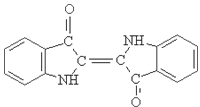

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.