wholesale industrial indigo

The Rise of Wholesale Industrial Indigo Trends and Transformations in the Textile Industry

Indigo, a dye with a rich history dating back thousands of years, has become a staple in the textile industry. Known for its deep blue hue, indigo has long been associated with denim, but its applications extend far beyond this realm. The wholesale industrial indigo market is witnessing significant transformations, driven by advancements in technology, sustainability, and changing consumer preferences. In this article, we explore the current trends in wholesale industrial indigo, its importance in global textile production, and the challenges and opportunities this sector faces.

The Historical Significance of Indigo

Indigo dye has been used for centuries, with evidence of its use dating back to ancient Egypt and Mesopotamia. Traditionally derived from the leaves of the indigofera plant, the dyeing process was labor-intensive and time-consuming. However, indigo's vibrant color and fade-resistant properties made it a prized commodity, leading to its trade along historic Silk Routes.

In the modern era, particularly with the rise of denim jeans in the 19th century, indigo saw a resurgence in popularity. But the methods of production have evolved dramatically. Synthetic indigo was developed in the late 19th century, providing a more uniform and cost-effective solution for mass production. Today, around 90% of the indigo used in the textile industry is synthetic, although natural indigo is experiencing a resurgence due to growing consumer interest in sustainable practices.

Current Trends in the Wholesale Industrial Indigo Market

1. Sustainability and Eco-Friendly Practices In recent years, the textile industry has faced increasing scrutiny regarding its environmental impact. The production of synthetic dyes, including indigo, often involves harmful chemicals and processes that can pollute water sources. As a response, many manufacturers are exploring sustainable alternatives. Natural indigo is being revived as a more eco-friendly option. Companies are also investing in closed-loop systems to minimize waste and reduce their carbon footprint.

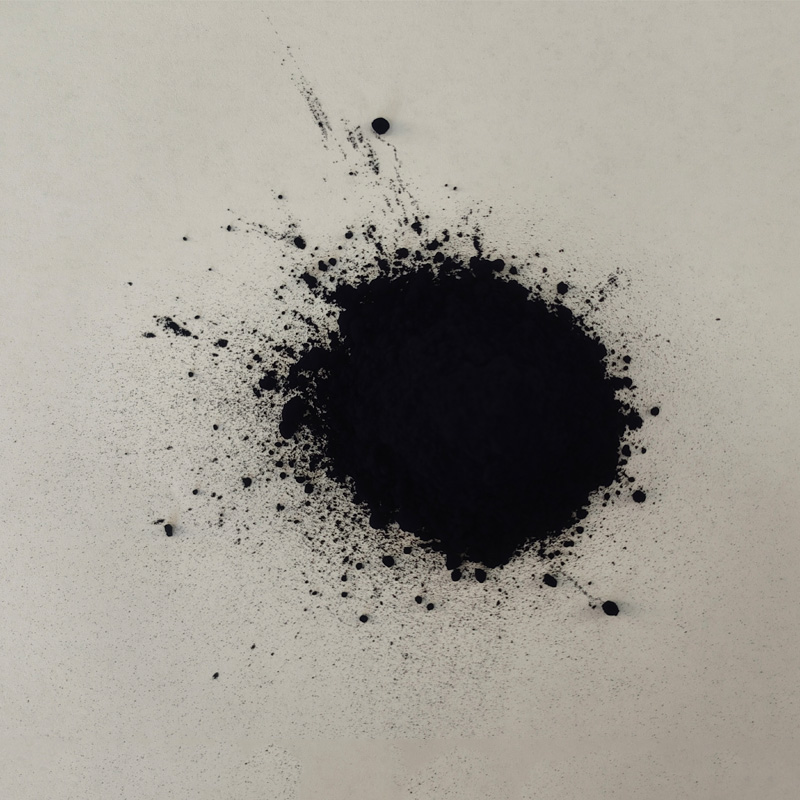

wholesale industrial indigo

2. Technological Innovations The integration of technology into the dyeing process is transforming the wholesale industrial indigo market. Digital dyeing techniques, which allow for precise control over color application, are gaining traction. These methods not only reduce dye waste but also enable quicker production times. Furthermore, innovations such as bioengineering and fermentation processes are being explored to produce sustainable indigo without relying on traditional agricultural methods.

3. Market Dynamics and Consumer Preferences The demand for indigo is being driven by evolving consumer preferences. Today's consumers are increasingly aware of the environmental impact of their purchases. This shift has led brands to promote the use of sustainable indigo in their products, from high-end fashion to everyday wear. Wholesale suppliers are adapting by offering a wider range of products that cater to brands seeking to emphasize their commitment to sustainability and ethical production practices.

Challenges in the Wholesale Industrial Indigo Sector

Despite the positive trends, the wholesale industrial indigo market faces several challenges. The fluctuating prices of raw materials, particularly for natural indigo, can impact production costs. Additionally, as brands compete to meet sustainability claims, ensuring transparency in the supply chain becomes paramount. Manufacturers must navigate complex sourcing strategies to provide assurance that their products meet these claims.

Another challenge is the need for innovation without compromising on quality. As new technologies and production methods emerge, there is a constant balance between maintaining the desirable characteristics of indigo dye—such as its intensity and durability—and implementing more sustainable practices.

Conclusion

The wholesale industrial indigo market is at a pivotal stage, balancing the rich history of this beloved dye with the demands of a modern, sustainability-focused world. As technological innovations continue to reshape the industry and consumer preferences shift towards more eco-friendly products, the future of indigo looks promising. Brands and manufacturers that can adapt to these changes while maintaining quality and transparency will likely thrive in this evolving landscape. Indigo not only represents a deep-seated tradition but also a potential path toward a more sustainable textile industry, reflecting the values of today's conscientious consumers.

-

Sulphur Black Dyes in Daily Use

NewsMay.07,2025

-

Indigo Dyeing for Daily Life

NewsMay.07,2025

-

Indigo Dye Production and Its Growing Demand

NewsMay.07,2025

-

Color That Lasts

NewsMay.07,2025

-

Bromo Indigo for Modern Use

NewsMay.07,2025

-

Blue From Nature

NewsMay.07,2025

-

The Timeless Color in Fashion and Textiles

NewsApr.10,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.