dyeing with indigo powder product

The Art of Dyeing with Indigo Powder A Timeless Tradition

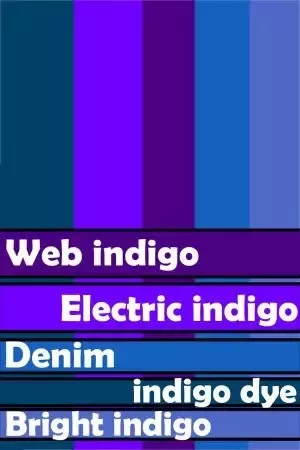

Indigo dyeing, a practice steeped in history and culture, has been captivating artisans and fashion enthusiasts for centuries. With its striking blue hues and natural roots, indigo powder offers a unique avenue for artistic expression. This age-old technique, derived from the leaves of the indigo plant, provides not only stunning colors but also a connection to tradition and sustainability in the art of fabric dyeing.

The Origins of Indigo Dye

Indigo dyeing can be traced back thousands of years, with evidence of its use found in ancient civilizations across Asia, Africa, and the Americas. The process begins with the leaves of the indigo plant, which are fermented to create a blue pigment known as indigo. Once dried and processed into a fine powder, this pigment can be used to dye fabrics, creating rich, deep colors that can transform the simplest piece of cloth into a work of art.

Throughout history, indigo dyeing has held significant cultural importance. In Africa, indigo was often used in the traditional textiles of the Yoruba and the Wolof peoples, symbolizing status and identity. In Asia, indigo-dyed garments were associated with protection and spirituality. The craft of indigo dyeing has often been passed down through generations, preserving not only the techniques but also the stories and heritage behind them.

The Process of Dyeing with Indigo Powder

The process of dyeing with indigo powder can be both complex and rewarding. To achieve the vibrant shades that are characteristic of indigo, a few specific steps must be followed

1. Preparation of the Fabric Before dyeing, the fabric, often cotton, needs to be scoured to remove any impurities or finishes. This initial step ensures that the dye adheres properly.

2. Creating the Dye Bath The indigo powder must be dissolved in a solution of water, sodium hydroxide, and thiourea dioxide. This mixture reduces the indigo to a soluble form, known as leuco indigo. The dye bath typically requires a specific pH level and temperature for optimal results.

dyeing with indigo powder product

3. Dyeing the Fabric The prepared fabric is submerged in the dye bath for a few minutes. As it is removed and exposed to air, the color begins to develop, transforming from a yellowish-green to a deep blue. This oxidation process is critical and can be repeated multiple times to achieve the desired intensity of color.

4. Post-Dyeing Treatment After reaching the desired shade, the fabric should be rinsed in cold water and allowed to dry. This step helps to fix the dye and enhance the fabric's durability.

The Beauty of Indigo Patterns

One of the most enchanting aspects of indigo dyeing is the various techniques used to create patterns and designs on the fabric. Shibori and batik are two popular methods that yield stunning results. Shibori involves folding, twisting, or binding the fabric to resist the dye, creating intricate designs. Batik, on the other hand, utilizes wax to create patterns before dyeing, resulting in beautiful contrasts.

These techniques offer endless possibilities for creative expression, making each piece unique. Whether used in fashion, home decor, or fine art, indigo-dyed fabrics provide a touch of elegance and individuality.

The Sustainable Choice

In an age where sustainability is increasingly important, indigo powder stands out as a natural alternative to synthetic dyes. The use of organic indigo not only reduces environmental impact but also supports sustainable farming practices. Moreover, the dyeing process is often less harmful to health compared to synthetic alternatives, making it a safer choice for artisans.

In conclusion, dyeing with indigo powder is not merely a craft; it is a celebration of history, culture, and sustainable practices. By exploring this beautiful art form, one can uncover a world that is rich in color, creativity, and tradition. Whether you are an artist, a craft enthusiast, or simply someone who appreciates the beauty of hand-dyed fabrics, indigo dyeing offers a timeless opportunity to connect with the past while fostering a sustainable future. Dive into the world of indigo, and let its captivating hues inspire your creative journey.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.