Optimizing Indigo Dyeing Techniques for Fabric Manufacturing Efficiency and Quality

Setting Indigo Dye in Fabric Manufacturing

Indigo dyeing is a time-honored technique, cherished for its rich, deep blue hues and vibrant cultural history. Today, it remains a popular choice in fabric manufacturing, particularly in the production of denim. As the fashion industry shifts towards sustainability, understanding the process of setting indigo dye in fabric has become increasingly important.

The indigo dyeing process begins with the extraction of the dye from the leaves of the Indigofera plant. This natural dye has been used for thousands of years, with its roots embedded in various cultures. Once the leaves are harvested, they undergo fermentation in water to transform them into a form that can effectively bind to fabric. The resulting dye is a complex mixture, allowing textiles to absorb the deep and vivid shades of indigo.

The setting of indigo dye in fabric involves several critical steps that ensure durability and vibrancy. One of the primary methods used in the textile industry is rope dyeing. In this process, the fabric is twisted into a rope-like structure and then submerged in the dye bath. This technique allows for greater control over the depth of color, as the fabric can be dipped multiple times to achieve the desired shade. Each immersion into the dye bath is followed by oxidation, where the fabric is exposed to air, allowing the dye to develop its characteristic blue hue.

After the dyeing process, setting the color is essential to prevent it from fading or washing out. Different methods are employed to fix the dye to the fabric effectively. One common practice is the use of mordants—substances that create a bond between the dye and the fabric fibers. For indigo dye, minerals like alum or iron can be utilized as mordants, enhancing colorfastness.

setting indigo dye in fabric manufacturer

The eco-friendliness of indigo dyeing cannot be overstated. With the textile industry increasingly striving for sustainable practices, natural indigo represents an appealing alternative to synthetic dyes, which often contain harsh chemicals. Manufacturers are embracing traditional dyeing techniques, which require less water and minimize environmental impact. Supporting local artisans and organic farming methods is a growing trend, further promoting sustainability in fabric manufacturing.

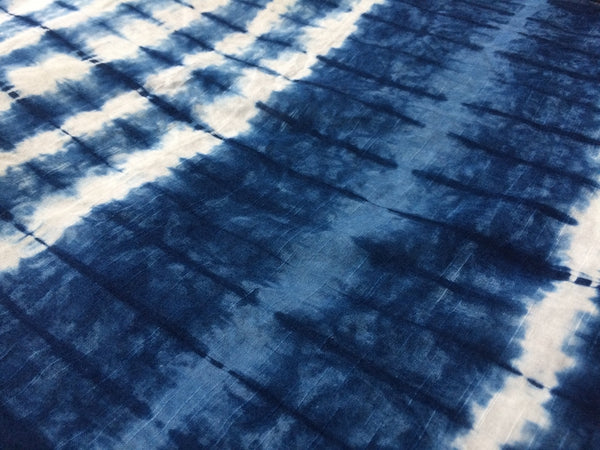

The versatility of indigo dye extends beyond traditional denim. Today, designers and manufacturers experiment with various techniques to create unique patterns and textures. Shibori, a Japanese tie-dye technique, is popular in contemporary fabric manufacturing. The distinct patterns achieved through this method add to the uniqueness of each piece, making indigo-dyed fabrics increasingly sought after in fashion.

Moreover, indigo dyeing has cultural significance, often embedded in the heritage of the regions where it is produced. Artisan communities worldwide use indigo dyeing as a means of preserving traditional crafts while providing sustainable incomes. By choosing indigo-dyed fabrics, consumers are supporting these communities and contributing to the revival of age-old techniques.

In conclusion, setting indigo dye in fabric manufacturing is a multifaceted process that encompasses tradition, sustainability, and creativity. As the demand for environmentally friendly textiles rises, understanding the methods and significance of indigo dyeing will continue to evolve. By appreciating the art and science of indigo dyeing, manufacturers can innovate while honoring a rich cultural legacy. As consumers become more aware of textile production processes, there is a collective shift towards choosing fabrics that are not only beautiful but also environmentally friendly, ensuring that the art of indigo dyeing thrives for generations to come.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.