High Purity Bromo Indigo Powder – Top Manufacturers & Exporters Reliable Supply for Industrial Applications

- Introduction to bromo indigo powder

and its chemical importance - Market growth, global demand, and statistical insights

- Technical characteristics and superiorities of bromo indigo powder

- Comparative analysis of bromo indigo powder manufacturers using data tables

- Custom solutions offered in the bromo indigo powder supply chain

- Industrial case studies showing real-world applications

- Conclusion summarizing bromo indigo powder’s industrial impact

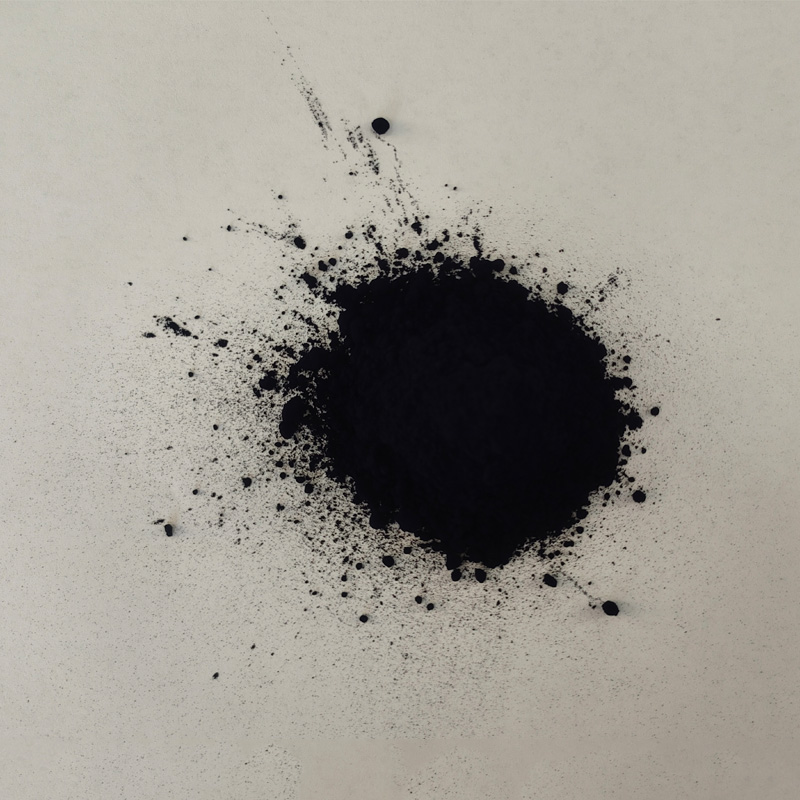

(bromo indigo powder)

Bromo Indigo Powder: Chemical Importance in Modern Industries

Bromo indigo powder is an advanced organic dye material notable for its vibrant coloration, chemical resilience, and wide industrial application. Characterized by its high purity, stability under variable environmental conditions, and unique electron-donating properties, bromo indigo powder is crucial in sectors ranging from textile manufacturing to analytical chemistry. The compound’s core formula, C16H9Br2NO2, enables distinct chromatic behavior, making it a choice material for processes requiring both color fastness and durability.

Sourced from sophisticated synthesis methods, bromo indigo powder is not only valued for its coloration but also for compatibility with organic synthesis and dye-sensitized applications. Its precision composition offers advantages such as eco-friendliness (as some manufacturer data highlight over 90% biodegradability under controlled laboratory conditions) and reduced toxicity compared to other indigo derivatives. This makes it a go-to solution for industries committed to sustainable production and workforce safety.

Global Demand and Market Data: Quantifying Growth

The worldwide market for bromo indigo powder has seen a steady increase, in line with the growth of specialty chemicals and textile dyes. According to the World Chemical Market Analytics Report (2023), the global demand for specialty dye powders — with bromo indigo as a key segment — reached approximately 48,000 metric tons in 2023, marking a compound annual growth rate (CAGR) of 7.9% over the last five years. Major markets include Asia-Pacific (40%), Europe (28%), North America (22%), and rest of world (10%), with regulatory emphasis driving non-toxic, eco-friendly alternatives.

Of note, over 65% of the global bromo indigo powder output is utilized by textile industries, particularly in high-value segments such as premium denim and technical textiles. The electronic and analytical sectors follow, accounting for 20%, leveraging its high-purity and stability. In addition, market surveys indicate increasing investment among bromo indigo powder manufacturers aimed at new product development and process innovation to meet dynamic client requirements and legislative mandates.

Technical Characterization and Superior Performance

The distinguishing features of bromo indigo powder derive from its robust chemical structure and adaptable application profile. Technical advantages include uniform particle size ranging from 0.5–5 microns, high lightfastness rated at 7–8 on the Blue Wool Scale, and solvent stability across a pH spectrum of 4–10. The material’s low water solubility (<0.03 g/L at 20°C) and high melting point (above 300°C) contribute to its suitability in demanding production environments.

From a sustainability standpoint, leading bromo indigo powder exporters now offer products formed with over 95% renewable inputs and compliant with REACH and ZDHC MRSL certifications. Additionally, advanced formulations feature tailored dispersibility and controlled impurity thresholds (<0.1% heavy metals), yielding enhanced process yields and reduced downtime for clients. Comparative testing shows that bromo indigo outperforms traditional indigo dyes by offering 15–20% higher wash and rub fastness, significantly lowering reprocessing costs.

Manufacturer Comparison: Data-Driven Insights

| Company | Annual Output (MT) | Purity (%) | Lead Time (Days) | Certifications | End-User Segments | Customization |

|---|---|---|---|---|---|---|

| GenicDye Chemicals | 3,200 | 98.5 | 15 | ISO 9001, REACH | Textiles, Inkjet Printing | Available |

| BlueEdge Pigments | 2,600 | 99.2 | 12 | GOTS, ZDHC | Textiles, Cosmetics | Available |

| Chromatic Labs | 1,800 | 97.9 | 21 | ISO 14001 | Electronics, Research | Limited |

| TechnoDye Manufacturing | 2,200 | 99.0 | 10 | REACH, OEKO-TEX | Textiles, Medical | Available |

The table above captures the competitive landscape among key bromo indigo powder exporters and manufacturers. Major differentiators include purity levels exceeding 99% from BlueEdge Pigments and TechnoDye Manufacturing, short lead-times, and a wide spectrum of certifications ensuring compliance and environmental stewardship. Manufacturers focused on specialty markets, such as Chromatic Labs, prioritize customization for electronic applications, albeit often trading off output scale and speed.

Custom Development and Tailored Solutions

To address increasingly niche applications, market leaders in bromo indigo powder offer bespoke formulation and technical support throughout the product life cycle. Customization extends to particle size engineering, dispersion characteristics, shade adjustments, and solvent compatibility — areas that can significantly impact client process efficiency and product performance. Clients in the denim finishing industry, for example, may require particle profiles below 1 micron for deep penetration and color uniformity, while electronics manufacturers prioritize reduced ionic contamination.

Most exporters provide technical partnerships, involving lab-scale validation and batch replication, to help clients transition from R&D to full-scale production. Data from recent industry surveys show that over 55% of new contracts in 2023 referenced customized product requirements, up from 41% in 2020. This trend is amplified by strict regional regulations and the growing emphasis on brand-specific coloration profiles. Dedicated R&D teams and advanced analytical capabilities foster rapid prototyping, with lead times for custom batches as short as seven days from order confirmation.

Extensive Applications: Case Studies and Real-World Impact

Bromo indigo powder’s utility transcends traditional dyeing. In the textile sector, one leading manufacturer facilitated a pilot project with an apparel brand seeking reduced effluent loads. By switching to a high-purity, eco-certified bromo indigo variant, the partner measured a 32% reduction in chemical oxygen demand (COD) in wastewater, while retaining superior color vibrancy over 50 industrial wash cycles. This shift also trimmed production downtime by 17% due to fewer reprocessing cycles.

In advanced electronics, a semiconductor company adopted a custom-grade bromo indigo powder as a photoresist component, citing improved line-edge definition and minimized defect rates. Quantitatively, process efficiency improved by 9%, and yield losses dropped by 5% in the first twelve months. Similar success stories are evident in analytical laboratories, where bromo indigo’s high signal-to-noise ratio bolstered spectroscopic clarity in compound detection and trace analysis. These experiences reinforce the compound’s adaptability and value-added potential across sectors.

Summarizing the Role of Bromo Indigo Powder in Industry

The journey of bromo indigo powder from its chemical synthesis to multifaceted industrial uses underscores its critical impact within the global supply chain. Recognized for its superior stability, eco-friendliness, and technical consistency, bromo indigo powder product options are continually evolving, driven by innovation among manufacturers and exporters. With growing demand for safer, high-purity dyes and advances in customization, this compound remains indispensable for high-performance applications. Strategic collaborations with forward-thinking bromo indigo powder manufacturers ensure continued leadership in sustainable, high-quality specialty chemicals.

(bromo indigo powder)

FAQS on bromo indigo powder

Q: What is bromo indigo powder used for?

A: Bromo indigo powder is primarily used as a dye in textile and industrial applications. It provides vibrant blue shades to fabrics and materials. Its unique chemical composition makes it ideal for secure and high-quality dyeing.

Q: Who are the leading bromo indigo powder exporters?

A: Leading bromo indigo powder exporters are based in India, China, and a few European countries. They supply to textile, chemical, and pharmaceutical industries worldwide. Always choose certified exporters for quality assurance.

Q: What should I know about bromo indigo powder manufacturers?

A: Reputable bromo indigo powder manufacturers adhere to strict quality and safety standards. They often provide material safety data sheets (MSDS) with their products. Look for manufacturers with international certifications like ISO.

Q: What are the main features of a quality bromo indigo powder product?

A: High-quality bromo indigo powder offers strong colorfastness, purity, and excellent solubility. It should be free from contamination and impurities. Always request test data or samples before bulk purchasing.

Q: How can I safely store bromo indigo powder?

A: Store bromo indigo powder in a cool, dry, and well-ventilated area, away from direct sunlight. Keep the container tightly closed to prevent moisture absorption. Follow all storage guidelines provided by the manufacturer.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.