- umAfrika

- Isi-Albania

- Isi-Amharic

- Isi-Arabhu

- Isi-Armenian

- Isi-Azerbaijani

- Isi-Basque

- IsiBelarusian

- Isi-Bengali

- Isi-Bosnia

- IsiBulgaria

- IsiCatalan

- Cebuano

- IsiCorsican

- IsiCroatia

- IsiCzech

- Isi-Danish

- IsiDashi

- IsiNgisi

- Isi-Esperanto

- Isi-Estonian

- IsiFinnish

- IsiFulentshi

- IsiFrisian

- IsiGalicia

- IsiGeorgia

- IsiJalimane

- isiGreki

- IsiGujarati

- IsiCreole saseHaiti

- hausa

- isi-hawaiian

- IsiHebheru

- Cha

- Miao

- IsiHungary

- Isi-Icelandic

- igbo

- Isi-Indonesian

- i-irish

- IsiNtaliyane

- IsiJapane

- Isi-Javanese

- Isi-Kannada

- kazakh

- I-Khmer

- IsiRwanda

- IsiKorea

- IsiKurdish

- IsiKyrgyz

- I-TB

- IsiLatini

- Isi-Latvian

- IsiLithuanian

- Isi-Luxembourgish

- IsiMacedonian

- UMalgashi

- Isi-Malay

- Isi-Malayalam

- IsiMaltese

- IsiMaori

- IsiMarathi

- IsiMongolia

- eMyanmar

- IsiNepali

- IsiNorwegian

- IsiNorwegian

- Isi-Occitan

- Isi-Pashto

- isiPheresiya

- IsiPolish

- IsiPutukezi

- IsiPunjabi

- IsiRomania

- IsiRashiya

- IsiSamoa

- IsiScottish Gaelic

- IsiSerbia

- IsiNgisi

- IsiShona

- Sindhi

- IsiSinhala

- IsiSlovak

- IsiSlovenian

- eSomalia

- ISpanishi

- IsiSundanese

- IsiSwahili

- IsiSwidi

- IsiTagalog

- Isi-Tajik

- IsiTamil

- IsiTatar

- Isi-Telugu

- IsiThai

- IsiTurkey

- IsiTurkmen

- Isi-Ukraine

- Isi-Urdu

- Isi-Uighur

- Isi-Uzbek

- IsiVietnamese

- Isi-Welsh

- Usizo

- Isi-Yiddish

- IsiYoruba

- Zulu

Bromo Indigo Synthetic Production Process

In the realm of textile dyes, bromo indigo stands out for its vibrant hues and versatility, particularly in denim manufacturing. As a wholesaler, we recognize the significance of understanding its synthetic production process, as well as the unique properties of i-bromo indigo blue futhi I-bromo indigo powder. This knowledge allows us to better serve manufacturers seeking high-quality, sustainable dye solutions. WUXIN GROUP, with its decades of expertise in dye production, has honed this process to deliver consistent, top-tier products.

Bromo Indigo Raw Material Preparation

- The synthetic production of bromo indigo begins with meticulous raw material preparation, a step critical to ensuring the final product’s quality. Key ingredients are sourced and purified to meet strict standards, as impurities can affect the dye’s color strength and stability. WUXIN GROUP, leveraging its 30-plus years of experience, selects raw materials that align with both performance and sustainability goals, laying the foundation for eco-friendly production.

- This stage involves precise measurements and mixing of precursors, which will later undergo chemical reactions to form the indigo base. Attention to detail here ensures that the subsequent bromination process—where bromine is introduced to enhance color properties—proceeds smoothly, resulting in the rich i-bromo indigo blue shade desired by denim manufacturers.

Bromo Indigo Blue Bromination and Purification

- The transformation from indigo to i-bromo indigo blue occurs during the bromination phase, where the indigo molecule undergoes a chemical reaction with bromine compounds. This step is carefully controlled to achieve the optimal level of bromination, which directly influences the dye’s color intensity and fastness. WUXIN GROUP’s advanced production facilities, including their Inner Mongolia plant with a dedicated bromo indigo line, ensure precise temperature and pressure conditions during this process.

- After bromination, the mixture undergoes purification to remove any unreacted substances or by-products. This purification is essential for enhancing the dye’s strength and ensuring it meets the stringent quality standards required for textile applications. The result is a concentrated i-bromo indigo blue compound ready for further processing into powder form.

Bromo Indigo Powder Formation and Drying

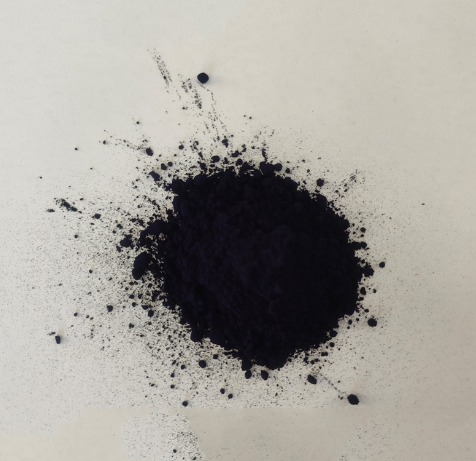

- Once purified, the bromo indigo compound is processed into I-bromo indigo powder, a form that offers ease of handling, storage, and application for manufacturers. This stage involves converting the liquid compound into a dry, granular or powdered substance through controlled drying techniques. The drying process is carefully monitored to prevent clumping and maintain the powder’s uniformity, which is crucial for consistent dyeing results.

- Bromo indigo powder typically has a dark blue appearance, with specific moisture content levels to ensure stability. WUXIN GROUP’s production process achieves the ideal moisture balance, ensuring the powder remains free-flowing and easy to dissolve during the dyeing process, while also extending its shelf life.

Bromo Indigo Quality Testing and Packaging

- Quality testing is a cornerstone of bromo indigo production, with rigorous checks conducted to verify strength, color consistency, and purity. Samples are tested for factors like color fastness, which ensures the dye retains its vibrancy through multiple washes—a key requirement for denim products. WUXIN GROUP’s in-house laboratory, staffed by experienced experts, conducts these tests to guarantee that each batch meets or exceeds industry standards.

- After passing quality checks, I-bromo indigo powder is packaged according to customer requirements, with options including 20kg cartons, 25kg bags, or larger 500-550kg bags. Packaging is designed to protect the powder from moisture, sunlight, and contamination, preserving its quality during transportation and storage. The table below outlines key specifications:

|

Ukubukeka |

Strength Range |

Moisture Content |

Validity |

Primary Usage |

|

Impushana eluhlaza okwesibhakabhaka |

100-110 |

≤2-5% |

2 years |

Denim dyeing |

- This attention to quality and packaging makes bromo indigo a reliable choice for manufacturers seeking consistent, high-performance dyes.

Bromo Indigo FAQS

What makes bromo indigo suitable for denim dyeing?

Bromo indigo is ideal for denim dyeing due to its vibrant, long-lasting color and excellent color fastness. It withstands multiple washes without significant fading, maintaining the denim’s desired appearance. Additionally, its versatility allows for a range of shades, from deep blues to vintage-inspired hues, giving designers flexibility in creating unique denim products.

How is bromo indigo blue different from regular indigo?

Bromo indigo blue differs from regular indigo due to the bromination process, which enhances its color intensity and stability. This results in a richer, more vibrant blue that offers better resistance to fading, making it particularly well-suited for denim that requires a bold, long-lasting appearance. The bromine addition also improves the dye’s performance in various washing and treatment processes.

What are the storage requirements for bromo indigo powder?

Bromo indigo powder should be stored in a cool, dry, well-ventilated warehouse with airtight packaging to prevent moisture absorption. It should be protected from sunlight and rain, and stored away from sources of ignition. Following these guidelines ensures the powder retains its quality and effectiveness for its full two-year validity period.

Is bromo indigo production environmentally friendly?

Yes, modern bromo indigo production, such as that by WUXIN GROUP, emphasizes eco-friendliness. The process reduces water consumption and minimizes harmful pollutants, aligning with the growing demand for sustainable fashion. This makes bromo indigo a responsible choice for brands looking to reduce their environmental footprint.

How is bromo indigo powder transported safely?

Bromo indigo powder is transported in packaging designed to resist moisture and physical damage, with precautions to avoid exposure to sunlight and rain. Transportation follows prescribed routes to ensure safety, and containers are loaded to prevent shifting during transit. These measures protect the powder’s quality and ensure it arrives in optimal condition for use.

-

Innovating Bromo Indigo Excellence

IzindabaAug.23,2025

-

Pioneering Indigo Plant Dye Excellence

IzindabaAug.23,2025

-

Leading Sulphur Black Dyes Enterprise

IzindabaAug.23,2025

-

Sulphur Black Dyes Light Resistance

IzindabaAug.23,2025

-

Indigo Blue Granular Industrial Uses

IzindabaAug.23,2025

-

The Timeless Art of Denim Indigo Dye

IzindabaJul.01,2025

-

The Rise of Sulfur Dyed Denim

IzindabaJul.01,2025

Isibabule Esimnyama

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.