make indigo dye

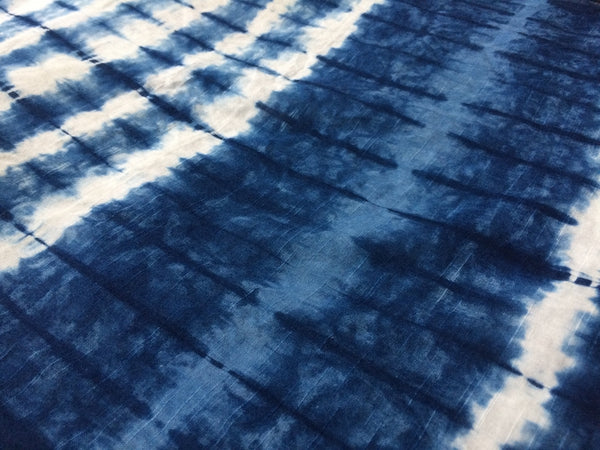

For those with real-world experience, the practice of dyeing with indigo involves an understanding of both the aesthetic and the scientific. It requires attention to the fabric being dyed, as different materials react uniquely to indigo. Natural fibers like cotton, silk, and wool often yield the best results due to their ability to bond effectively with the dye molecules. The environmental impact of indigo dyeing is a topic of growing concern within the industry. Sustainable practices are gaining attention, emphasizing the use of natural fermentation over chemical reductions and promoting water conservation throughout the dyeing process. Educated industry professionals are pioneering methods to recycle dye baths and minimize waste, ensuring that indigo dyeing can continue to captivate future generations without compromising ecological stability. Trust in indigo dye, particularly for products like textiles and artwork, is established through transparency in sourcing and production. Artisans and manufacturers who share their methodology, from plant cultivation to final product, establish credibility and earn consumer trust. Ultimately, mastering indigo dye demands a balance of historical reverence and innovative foresight. This craftsmanship links the past and the future, providing dye enthusiasts and professionals alike with a profound sense of connection and purpose in their work. As the love for indigo continues to grow, its applications and methods evolve, inviting both seasoned dyers and newcomers to explore its depths with both passion and responsibility.

-

Sulphur Black Dye: Eco-Friendly, High Fastness for Textiles

NewsAug.28,2025

-

Innovating Bromo Indigo Excellence

NewsAug.23,2025

-

Pioneering Indigo Plant Dye Excellence

NewsAug.23,2025

-

Leading Sulphur Black Dyes Enterprise

NewsAug.23,2025

-

Sulphur Black Dyes Light Resistance

NewsAug.23,2025

-

Indigo Blue Granular Industrial Uses

NewsAug.23,2025

-

Bromo Indigo Synthetic Production Process

NewsAug.23,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.