Light Indigo Color Company: Premium Pigments & Dyes Manufacturer

Introduction to Advanced Indigo Dye Solutions

In the highly competitive textile and pigment industries, the demand for consistent, high-quality colorants is paramount. As a leading light indigo color company, we specialize in the synthesis, production, and global distribution of advanced Indigo Blue Vat Blue. Our commitment extends beyond mere manufacturing; we provide comprehensive solutions that address the nuanced requirements of modern industrial applications. This detailed exposition will delve into the critical aspects of light indigo color production, its technical advantages, diverse application scenarios, and the stringent quality controls that underscore its reliability. Our focus remains on delivering products that not only meet but exceed international standards, ensuring optimal performance and sustainability for our partners worldwide.

Industry Trends and Market Dynamics for Light Indigo Color

The global market for indigo colorants is currently shaped by several key trends, particularly within the textile sector. There's a pronounced shift towards sustainable manufacturing practices, driven by increasing consumer awareness and regulatory pressures. This translates to a heightened demand for indigo dyes produced with eco-friendly methodologies, minimizing effluent and energy consumption. Furthermore, innovations in dyeing technology, such as foam dyeing and nitrogen dyeing, are gaining traction, requiring indigo products with superior dispersion properties and consistent particle size. The rise of fast fashion, coupled with a renewed interest in classic denim aesthetics, continues to fuel demand, while the luxury segment seeks highly purified, stable indigo for premium fabric applications. Light indigo color company expertise is crucial in navigating these evolving demands, offering tailored solutions that align with both environmental stewardship and economic viability. Emerging markets in Asia and Latin America are also significant growth drivers, increasing the need for efficient logistics and robust supply chains from experienced light indigo color exporters.

Detailed Manufacturing Process of Indigo Blue Vat Blue

The production of Indigo Blue Vat Blue by a specialized light indigo color company involves a meticulously controlled chemical synthesis and subsequent processing stages to ensure product purity, consistency, and performance. Our process adheres to stringent international standards, emphasizing both efficiency and environmental responsibility.

Process Flow Overview:

1. Raw Material Sourcing

Acquisition of high-purity aniline, sodium hydroxide, formaldehyde, and other key precursors, all subjected to strict incoming quality inspection.

2. Indoxyl Synthesis

Controlled reaction (e.g., Heumann synthesis or modified processes) to form indoxyl intermediates under specific temperature and pressure conditions.

3. Oxidation & Precipitation

Air oxidation of indoxyl to form insoluble indigo, followed by careful precipitation for optimal crystal formation.

4. Filtration & Washing

Separation of crude indigo from reaction byproducts, followed by multiple washing cycles to remove impurities and residual chemicals, ensuring high purity.

5. Milling & Particle Size Control

Wet or dry milling processes to achieve the desired particle size distribution, critical for consistent shade depth, dispersion, and dyeing efficiency. This directly impacts dye uptake and fastness properties.

6. Standardization & Quality Control

Final product standardization for color strength, shade, and chemical composition. Rigorous testing against internal benchmarks and international standards like ISO and AATCC.

7. Drying & Packaging

Drying to optimal moisture content using techniques like spray drying or oven drying. Packaging in various forms (powder, granules, paste) according to client specifications, ensuring product stability and ease of handling.

Our target industries for Indigo Blue Vat Blue primarily include textile manufacturing (especially denim, cotton, and linen), as well as specialty applications in printing inks and some non-textile coloring. The emphasis on particle size control directly enhances dyeing advantages such as superior color yield, excellent levelness, and reduced speckiness, leading to significant energy savings during application due to optimized dye uptake. The robust chemical structure of our Indigo Blue Vat Blue ensures exceptional corrosion resistance within the dyed fabric, contributing to a longer service life and vibrant color retention even after numerous washes. This meticulous process solidifies our position as a premier light indigo color factory committed to excellence.

Technical Specifications and Quality Parameters

The performance of indigo dye hinges on precise technical specifications. Our Indigo Blue Vat Blue products are characterized by stringent quality control measures, ensuring consistent batch-to-batch quality vital for industrial applications. Below is a typical specification table, reflecting our commitment to superior light indigo color product quality, validated by ISO 9001 and REACH compliance.

Product Specification: Indigo Blue Vat Blue (Selected Grade)

| Parameter | Unit | Typical Value | Test Method / Standard |

|---|---|---|---|

| Color Index Name | - | Vat Blue 1 | CI. 73000 |

| Purity (as Indigo) | % | ≥ 94.0 | HPLC |

| Moisture Content | % | ≤ 0.5 | KF Titration |

| Particle Size (D50) | μm | 1.0 - 5.0 | Laser Diffraction |

| Heavy Metals (Pb, As, Cd, Hg) | ppm | ≤ 5 total | ICP-OES / EPA 3050B |

| Color Strength | % | 100 ± 3 | Spectrophotometry (relative to standard) |

| pH (1% aqueous solution) | - | 7.0 - 9.0 | Electrometric Method |

| Light Fastness | Scale | 7-8 | ISO 105 B02 |

| Wash Fastness | Scale | 4-5 | ISO 105 C06 |

These parameters are critical for predicting dye performance in various applications. For instance, a tightly controlled particle size (D50) is essential for uniform dye penetration and minimizing filter clogging in continuous dyeing processes. High purity ensures consistent shade reproduction and prevents undesirable side reactions, while excellent fastness properties (Light and Wash) guarantee the durability and aesthetic longevity of the finished goods. Our comprehensive testing protocols ensure that every batch of light indigo color products meets these rigorous benchmarks.

Application Scenarios and Technical Advantages

Indigo Blue Vat Blue, supplied by a leading light indigo color company, finds its primary and most significant application in the textile industry, particularly in denim production. However, its unique properties extend its utility to several other specialized sectors.

Primary Application Scenarios:

- Denim Manufacturing: The iconic blue hue of denim is almost exclusively achieved using indigo. Our high-purity indigo ensures excellent ring dyeing effects, where the dye primarily coats the surface of the cotton fibers, allowing for the characteristic wash-down and fading patterns highly prized in denim garments. The ability to control particle size precisely allows for optimized dye penetration and exhaustion, crucial for both consistent shade development and minimizing effluent.

- General Cotton and Cellulosic Dyeing: Beyond denim, indigo is utilized for dyeing other cotton fabrics, viscose, and linen, imparting durable, light-fast blue shades ideal for workwear, casual apparel, and home textiles.

- Printing Inks: In specialized graphic arts and textile printing, indigo pigments offer superior lightfastness and resistance to fading compared to many other blue pigments, making them suitable for outdoor applications or long-lasting prints.

- Non-Textile Applications: Certain grades of indigo can be found in niche applications such as artists' pigments and specialty coatings where its unique color and chemical stability are valued.

Technical Advantages of Our Indigo Blue Vat Blue:

- Superior Colorfastness: Our indigo exhibits exceptional fastness to light, washing, and rubbing (crocking), ensuring garments retain their vibrant blue hue over extended periods, even under harsh conditions. This translates to increased product longevity and customer satisfaction.

- High Purity & Consistency: Minimized impurities lead to predictable dyeing results, fewer rejections, and reduced downtime in manufacturing. Consistent particle size distribution allows for uniform dispersion and penetration, critical for achieving level dyeing.

- Enhanced Dyeing Efficiency: Optimized solubility in its leuco form (reduced state) and excellent dispersibility of the pigment form lead to higher dye uptake, reducing bath exhaustion, chemical consumption, and overall operational costs for textile manufacturers.

- Environmental Profile: Committed to sustainable practices, our manufacturing process aims to reduce waste and energy consumption. Our product meets stringent environmental standards such as REACH, ZDHC, and OEKO-TEX, providing a greener choice for demanding industries.

- Versatility: Available in various forms (powder, granules, liquid pre-reduced), our indigo products cater to different dyeing methodologies, including rope dyeing, slasher dyeing, and open-width dyeing, offering flexibility to our clients.

Vendor Comparison: Selecting the Right Light Indigo Color Manufacturer

Choosing the right light indigo color manufacturers is a strategic decision that directly impacts product quality, supply chain stability, and overall cost-efficiency. While price is often a consideration, factors such as product consistency, technical support, and ethical sourcing are equally, if not more, critical for B2B procurement. This comparison highlights key differentiators.

Comparison of Key Attributes Among Light Indigo Color Suppliers

| Attribute | Tier 1 Manufacturer (Our Company) | Typical Local Supplier | Economy Provider |

|---|---|---|---|

| Product Purity (%) | ≥ 94.0 | 90.0 - 93.0 | < 90.0 |

| Batch Consistency | Excellent (CV < 1%) | Good (CV 1-3%) | Variable (CV > 3%) |

| Certifications | ISO 9001, REACH, OEKO-TEX, ZDHC | ISO 9001 (basic) | Few/None |

| Technical Support | Comprehensive, on-site/remote | Basic, limited scope | Minimal to none |

| Supply Chain Reliability | Global, multi-source, robust | Regional, single-source risk | Often unpredictable |

| Customization Options | Extensive (particle size, formulation) | Limited | None |

| Environmental Compliance | Leading (wastewater, energy efficiency) | Standard adherence | Minimal to non-compliant |

This comparison illustrates that investing in a reliable light indigo color company, even if the initial light indigo color pricelist appears higher, often leads to significant long-term savings through reduced production issues, consistent quality, and enhanced brand reputation due to superior end-product performance and sustainability credentials. The expertise of established light indigo color factories offers unparalleled value.

Customized Solutions and Collaborative Development

Recognizing that off-the-shelf solutions may not always perfectly align with unique operational requirements, our light indigo color company excels in providing customized solutions. Our dedicated R&D team works in close collaboration with clients to develop indigo formulations tailored to specific processing conditions, target shades, and end-use performances.

Areas of Customization:

- Particle Size Distribution: We can engineer indigo products with specific particle size ranges to optimize dispersion for foam dyeing, improve penetration for rope dyeing, or achieve particular wash-down effects for specialized denim finishes.

- Formulation (Powder, Granules, Paste): Depending on the client's equipment and safety protocols, we can supply indigo in various physical forms. Pre-reduced liquid indigo, for instance, offers advantages in terms of handling safety, dust reduction, and ease of dissolution, thereby improving the efficiency of the dyeing process.

- Purity and Impurity Profile: For highly sensitive applications or those requiring ultra-low heavy metal content, we can refine our manufacturing process to meet exceptionally strict purity standards, often exceeding standard industry benchmarks.

- Color Strength & Shade Matching: Our technical team can work with customers to develop indigo with adjusted color strength for specific recipes or to fine-tune the shade to match proprietary color palettes, ensuring brand consistency.

This bespoke approach positions us as more than just a supplier; we function as a strategic partner in product development, helping clients achieve competitive advantages and meet evolving market demands. Our comprehensive light indigo color service ensures full support from concept to commercialization.

Application Case Studies

Real-world applications demonstrate the tangible benefits of partnering with a quality light indigo color company. These case studies highlight how our Indigo Blue Vat Blue products contribute to enhanced performance and operational efficiency for our clients.

Case Study 1: Optimizing Denim Production for a Global Brand

A major international denim brand faced challenges with inconsistent shade depth and excessive water consumption during its rope dyeing process. After a thorough consultation, our technical team recommended a specific grade of our Indigo Blue Vat Blue, provided in a highly dispersible granular form, along with optimized reduction agent concentrations. By leveraging our product's precise particle size distribution and high purity, the client achieved:

- 20% reduction in indigo consumption due to improved dye uptake.

- 15% decrease in water usage for rinsing due to lower impurity levels.

- 98% batch-to-batch shade consistency, significantly reducing re-dyeing and material waste.

- Enhanced light and wash fastness, elevating the perceived quality and longevity of their denim products.

This collaboration resulted in substantial cost savings and strengthened the brand's commitment to sustainable production, reinforcing the value of a premium light indigo color product.

Case Study 2: Innovative Pigment for Eco-Friendly Textile Printing

A specialty textile printing company aimed to develop a new line of eco-friendly prints using natural dyes, but struggled with the poor lightfastness of existing options. Our R&D team worked with them to formulate a unique indigo pigment dispersion, specifically designed for direct-to-garment (DTG) printing. This customized solution offered:

- Superior lightfastness (Grade 7-8), matching synthetic pigment performance.

- Excellent compatibility with water-based binder systems, ensuring printability.

- Reduced environmental footprint through a non-toxic formulation and efficient pigment utilization.

- Vibrant, stable blue shades that withstand rigorous washing without significant fading.

This case illustrates our capability to innovate beyond traditional dyeing, providing advanced light indigo color products for diverse and emerging applications.

Frequently Asked Questions (FAQ)

Q1: What are the primary forms of Indigo Blue Vat Blue offered?

A1: We offer Indigo Blue Vat Blue in various forms, including powder (standard and fine grades), granules, and pre-reduced liquid paste (30% or 20% concentration). The choice depends on the client's dyeing equipment, safety protocols, and desired operational efficiency.

Q2: How does your light indigo color company ensure environmental compliance?

A2: Our manufacturing processes adhere to strict environmental regulations and international standards such as REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals), ZDHC (Zero Discharge of Hazardous Chemicals), and OEKO-TEX Standard 100. We invest in advanced wastewater treatment and energy-efficient production methods to minimize our ecological footprint.

Q3: What is the typical lead time for large orders?

A3: For standard products, our lead time typically ranges from 10 to 20 business days for container111-load quantities, depending on the destination and current production schedule. For customized formulations, lead times will be provided after detailed project scope definition. We maintain strategic inventory levels to ensure prompt fulfillment for urgent requirements.

Q4: Do you provide technical support during product integration?

A4: Absolutely. Our dedicated technical support team offers comprehensive assistance, from initial product selection and sample testing to on-site guidance during industrial-scale application. We can help optimize dyeing parameters, troubleshoot issues, and provide recommendations for achieving specific effects. This is a core part of our light indigo color service commitment.

Q5: What warranty and after-sales commitments do you offer?

A5: We guarantee that our Indigo Blue Vat Blue products will meet the specifications outlined in our technical data sheets and agreed-upon purity standards for a period of 12 months from the date of manufacture, provided they are stored under recommended conditions. Our after-sales support includes product traceability, detailed Certificates of Analysis (CoA), and a responsive customer service team for any quality-related inquiries or technical assistance post-purchase.

Conclusion

As a premier light indigo color company, our mission is to deliver unparalleled quality and service in the global market for Indigo Blue Vat Blue. Through rigorous adherence to international standards, continuous innovation in manufacturing processes, and a steadfast commitment to sustainability, we provide products that not only meet the highest technical specifications but also contribute to the long-term success and environmental responsibility of our clients. Our expertise as light indigo color manufacturers ensures a reliable supply of superior indigo, backed by comprehensive technical support and bespoke solutions designed to optimize your operations and elevate your end products.

References

- Cheung, P. S. (2009). The Chemistry of Vat Dyes. In Industrial Dyes: Chemistry, Properties, Applications (pp. 37-52). Wiley-VCH.

- Böhmer, M. (2015). Indigo. In Ullmann's Encyclopedia of Industrial Chemistry. Wiley-VCH.

- International Organization for Standardization (ISO) official website. www.iso.org

- American Association of Textile Chemists and Colorists (AATCC) official website. www.aatcc.org

- Zero Discharge of Hazardous Chemicals (ZDHC) Foundation official website. www.roadmaptozero.com

-

Innovating Bromo Indigo Excellence

NewsAug.23,2025

-

Pioneering Indigo Plant Dye Excellence

NewsAug.23,2025

-

Leading Sulphur Black Dyes Enterprise

NewsAug.23,2025

-

Sulphur Black Dyes Light Resistance

NewsAug.23,2025

-

Indigo Blue Granular Industrial Uses

NewsAug.23,2025

-

Bromo Indigo Synthetic Production Process

NewsAug.23,2025

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

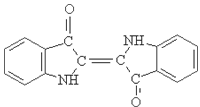

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.