Leading Light Indigo Color Company | Premium Quality Pigments

Unlocking Textile Excellence: The World of Light Indigo Color Production

In the dynamic landscape of textile and dye manufacturing, the demand for high-quality, sustainable, and consistent coloring agents remains paramount. Central to this sector is the production of light indigo color, a foundational element for denim and various textile applications worldwide. As a leading light indigo color company, we specialize in delivering superior Indigo Blue Vat Blue, engineered for optimal performance and environmental responsibility. This comprehensive overview delves into the intricate aspects of light indigo color manufacturing, its technical specifications, diverse applications, and the competitive advantages offered by a dedicated light indigo color manufacturer. We aim to provide B2B decision-makers and technical professionals with the insights needed to navigate the complexities of this essential industrial product.

The global textile industry continues to evolve, driven by consumer preferences for durable, aesthetically pleasing, and eco-conscious products. This trend directly influences the requirements for dye manufacturers, who must innovate to meet stringent quality and sustainability benchmarks. Our focus as a specialized light indigo color company is on advancing production methodologies and ensuring our Indigo Blue Vat Blue products consistently exceed market expectations, positioning us among the top light indigo color manufacturers globally.

The Advanced Manufacturing Process of Indigo Blue Vat Blue

The production of Indigo Blue Vat Blue, a cornerstone of the light indigo color spectrum, is a sophisticated chemical synthesis process requiring precision and adherence to strict quality controls. Our methodology ensures the highest purity and consistency, crucial for predictable dyeing outcomes.

Key Stages in Light Indigo Color Production:

- Raw Material Preparation (Isatin/Aniline Derivatives): The process typically begins with the preparation of key precursors, such as isatin or aniline, which undergo a series of reactions. Purity of these starting materials is rigorously checked to avoid contaminants that could affect the final product's hue or performance.

- Indole Synthesis: Through controlled condensation reactions, an indole derivative is formed. This step is critical, as the molecular structure at this stage largely dictates the final dye's characteristics. Temperatures, pressures, and reagent ratios are meticulously monitored.

- Dimerization and Oxidation: The indole derivative then undergoes dimerization, typically in the presence of an oxidizing agent. This forms the indigo molecule. Precise control over oxidation conditions is vital to achieve the desired shade and prevent over-oxidation, which can lead to unwanted by-products.

- Purification and Isolation: The crude indigo is subjected to multiple purification steps, including filtration, washing, and recrystallization. This removes unreacted raw materials, by-products, and impurities, ensuring the high purity required for textile applications.

- Drying and Milling: The purified indigo paste is then carefully dried to a specific moisture content. This is followed by milling, where the dye is ground into a fine, uniform powder or granular form, optimizing its dispersibility and solubility in the dyeing vat. This process ensures the consistent quality expected from a dedicated light indigo color company.

- Quality Control and Packaging: Every batch undergoes extensive testing for purity, shade, strength, and particle size distribution. Once approved, the product is packaged in hermetically sealed containers to prevent contamination and maintain stability.

Our facilities, as a leading light indigo color factory, operate under stringent quality management systems, including ISO 9001:2015 for quality management and ISO 14001:2015 for environmental management. These certifications ensure that every kilogram of Indigo Blue Vat Blue meets international standards for quality, safety, and environmental responsibility. Target industries for our products include textiles (denim, apparel, home furnishings), and specialty coatings. Our commitment to advanced manufacturing practices translates into benefits such as enhanced color fastness, superior shade consistency, and reduced environmental impact for our clients.

Image 1: Advanced manufacturing facility for light indigo color company products.

Technical Specifications of Indigo Blue Vat Blue

Understanding the technical parameters of Indigo Blue Vat Blue is crucial for optimal application and performance in various industrial processes. Our light indigo color product, Indigo Blue Vat Blue, adheres to strict specifications to ensure reliability and consistent dyeing results.

| Parameter | Value/Range | Testing Method | Significance |

|---|---|---|---|

| Color Index Name | Vat Blue 1 (C.I. 73000) | N/A | Universal identification for the dye. |

| Purity | ≥ 94% (Typically 96-98%) | HPLC, Spectrophotometry | Ensures consistent shade, strength, and minimizes by-products. |

| Moisture Content | ≤ 1.0% | Karl Fischer Titration, Oven Drying | Affects dye weight, stability, and dispersibility. |

| Particle Size (D50) | Typically 2-5 microns (micronized grade) | Laser Diffraction | Influences dispersibility, penetration into fibers, and color uniformity. |

| Light Fastness (ISO 105-B02) | 7-8 (Excellent) | Blue Wool Scale | Resistance to fading under light exposure. Critical for textiles. |

| Wash Fastness (ISO 105-C06) | Grade 4-5 (Very Good to Excellent) | Multi-fiber adjacent fabrics | Resistance to color loss during laundering. |

| Rubbing Fastness (ISO 105-X12) | Dry: 4-5, Wet: 3-4 (Good to Excellent) | Crockmeter Test | Resistance to color transfer when rubbed, especially important for denim. |

| Reduction Potential | Standard redox potential | Electrochemical methods | Key for vat dyeing process, ensuring proper leuco form creation. |

| Heavy Metal Content | Below detectable limits (e.g., | ICP-OES, AAS | Compliance with ecological textile standards (e.g., OEKO-TEX, REACH). |

These detailed specifications underscore our commitment as a light indigo color company to producing not just a dye, but a highly engineered chemical product. The consistently high purity and optimal particle size directly translate to enhanced dyeing efficiency, reduced waste, and superior final product quality for our clients utilizing our light indigo color products.

Application Scenarios and Technical Advantages

The versatility and inherent advantages of Indigo Blue Vat Blue make it indispensable across numerous industries, primarily textiles. Our light indigo color products are designed to offer maximum performance in these diverse application scenarios.

Primary Application Scenarios:

- Denim Manufacturing: This is the most iconic application. Indigo Blue Vat Blue is used to dye cotton yarns, giving denim its characteristic blue color. The unique property of indigo to selectively dye the surface of fibers, allowing for wash-down effects, is crucial for denim aesthetics.

- Textile Printing: While less common than dyeing, indigo can be used in specialized printing applications for patterns that mimic traditional resist-dyeing techniques.

- Workwear and Uniforms: Due to its excellent light fastness and wash fastness, indigo is a preferred choice for workwear fabrics that require durability and color retention under harsh conditions and frequent laundering.

- Arts and Crafts: Traditional dyeing techniques, from shibori to tie-dye, heavily rely on indigo for its vibrant blues and ease of use in vat dyeing.

Technical Advantages of Our Light Indigo Color:

- Superior Color Fastness: Our Indigo Blue Vat Blue exhibits exceptional fastness to light, washing, and rubbing, ensuring the longevity and vibrancy of dyed fabrics. This is particularly vital for products like denim, which undergo repeated washing and exposure to UV light.

- High Purity & Consistency: The stringent manufacturing process results in a dye with minimal impurities, leading to uniform dyeing and predictable shade reproduction batch after batch. This reduces the need for re-dyeing and optimizes production efficiency.

- Excellent Dispersibility and Solubility: Micronized grades of our indigo powder offer superior dispersibility in water and efficient solubility in the alkaline reduction vat, facilitating smooth and even dye uptake by textile fibers.

- Environmental Responsibility: We employ eco-friendly production methods, minimizing waste and ensuring our products comply with international environmental standards like REACH and OEKO-TEX. This positions us as a responsible light indigo color company committed to sustainability.

- Energy Efficiency in Dyeing: With optimized particle size and purity, our indigo allows for more efficient dye absorption, potentially reducing the required dyeing cycles or concentrations, thereby contributing to energy savings in textile mills.

Image 2: Versatile applications of light indigo color company products in textiles.

These technical advantages not only enhance the aesthetic appeal and durability of finished products but also contribute significantly to the operational efficiency and ecological footprint of our clients, making our light indigo color products a preferred choice in the global market.

Vendor Comparison and Market Positioning

The market for light indigo color, specifically Indigo Blue Vat Blue, is competitive, with numerous light indigo color exporters and suppliers globally. Differentiating factors often extend beyond price to encompass quality, reliability, sustainability, and service. Below is a comparison demonstrating the strengths of a top-tier light indigo color company in the market.

| Feature | Our Company (Leading Supplier) | Typical Competitor A (Established) | Typical Competitor B (Emerging) |

|---|---|---|---|

| Product Purity (%) | ≥ 96% | 92-95% | 88-92% |

| Batch Consistency | Excellent (Minimal ∆E) | Good (Moderate ∆E) | Fair (Noticeable ∆E) |

| Environmental Certifications | ISO 14001, REACH, OEKO-TEX | ISO 14001 | Basic local certifications |

| Technical Support | Comprehensive, Global | Regional, Standard | Limited, Basic |

| Customization Options | High (Particle size, formulation) | Moderate | Low |

| Lead Time (Typical) | 2-4 weeks | 3-5 weeks | 4-8 weeks |

| Pricing Structure | Competitive for Premium Quality | Standard Market Price | Budget-focused (often lower purity) |

Our market positioning is defined by an unwavering commitment to quality and consistency. We understand that for industrial applications, a slight variation in dye quality can lead to significant production issues and waste. Therefore, our focus as a light indigo color company is on providing a product that minimizes these risks, offering predictable results and superior value over time, despite potentially higher upfront light indigo color pricelist points compared to lower-grade alternatives. This strategic approach strengthens our role as reliable light indigo color suppliers and a preferred light indigo color factory for discerning clients.

Customized Solutions and Comprehensive Service Offerings

Recognizing that every client's needs are unique, especially in large-scale industrial operations, our light indigo color company provides comprehensive customized solutions. This dedication to tailored support extends across product formulation, packaging, and logistical arrangements, forming the core of our light indigo color service.

Tailored Solutions for Diverse Requirements:

- Custom Particle Size: For specific dyeing machinery or fiber types, an optimal particle size distribution can significantly impact dye uptake and efficiency. We can adjust the milling process to produce Indigo Blue Vat Blue with custom D50 values.

- Formulation Adjustments: While Indigo Blue Vat Blue is standardized, minor adjustments to its formulation can enhance dispersibility, stability in certain vat conditions, or optimize for specific textile pre-treatments.

- Packaging Options: From bulk bags (e.g., 500kg, 1000kg) to smaller drums or customized packaging solutions, we offer flexibility to integrate seamlessly with client production lines and storage capabilities.

- Technical Consulting: Our team of expert chemists and textile engineers provides invaluable technical consultation, assisting clients in optimizing their dyeing processes, troubleshooting issues, and achieving desired color outcomes with our light indigo color products.

- Supply Chain Management: We offer robust supply chain solutions, including inventory management, just-in-time delivery, and global logistics coordination, to ensure a consistent and reliable supply of Indigo Blue Vat Blue, regardless of geographical location.

Our dedication to comprehensive service ensures that clients receive not just a product, but a complete solution tailored to their operational demands. This partnership approach distinguishes us as a premier light indigo color company, committed to fostering long-term relationships through exceptional product quality and unparalleled customer support.

Real-World Application Case Studies and Customer Experience

Our commitment to quality and service is best reflected in the successful outcomes achieved by our clients globally. These case studies highlight the tangible benefits of partnering with a leading light indigo color company.

Case Study 1: Denim Mill Optimization in Southeast Asia

A major denim manufacturer in Southeast Asia faced challenges with inconsistent shade variations and excessive dye consumption, leading to increased costs and production delays. Upon switching to our Indigo Blue Vat Blue, the mill observed:

- Shade Consistency: A 15% reduction in shade variation across production batches due to the high purity and consistent particle size of our dye.

- Dyeing Efficiency: A 7% reduction in overall dye consumption, attributed to optimized dispersibility and deeper fiber penetration.

- Reduced Rework: Significant decrease in re-dyeing requirements, improving lead times and reducing energy consumption.

"Switching to their Indigo Blue Vat Blue significantly streamlined our denim production. The consistency is unmatched, directly impacting our bottom line and allowing us to meet tighter deadlines." – Production Manager, Leading Denim Producer.

Case Study 2: Eco-Friendly Textile Initiative in Europe

A European textile brand, committed to sustainable fashion, sought a partner whose light indigo color company products not only delivered superior performance but also adhered to stringent environmental standards. Our partnership enabled them to:

- Achieve Certifications: Easily pass OEKO-TEX Standard 100 and REACH compliance for their dyed fabrics, crucial for market access.

- Enhance Brand Image: Communicate a strong commitment to sustainability to their consumers, utilizing our eco-friendly production credentials.

- Maintain High Quality: Despite the focus on sustainability, there was no compromise on the vividness or fastness of the indigo blue shade.

Image 3: Demonstrating superior quality in textiles from a trusted light indigo color company.

These instances exemplify the direct impact of high-quality Indigo Blue Vat Blue and dedicated customer support on operational efficiency, product integrity, and market competitiveness. We pride ourselves on these partnerships, continually striving to deliver value that goes beyond the product itself.

Quality Assurance, Certifications, and Industry Authoritativeness

Our position as a trusted light indigo color company is built on a foundation of rigorous quality assurance and adherence to international standards. This commitment ensures that every batch of Indigo Blue Vat Blue meets the highest benchmarks for purity, performance, and environmental compliance.

Certifications and Compliance:

- ISO 9001:2015: Certified for Quality Management Systems, ensuring consistent processes and continuous improvement across all manufacturing operations.

- ISO 14001:2015: Certified for Environmental Management Systems, affirming our commitment to minimizing environmental impact and promoting sustainable practices.

- REACH Compliance: Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) compliant, ensuring that our products are safely managed throughout their lifecycle.

- OEKO-TEX Standard 100: Our Indigo Blue Vat Blue is suitable for use in textiles certified by OEKO-TEX, indicating that it is free from harmful substances and safe for human ecology.

Authoritative References & Partner Clients:

With over [X, e.g., 20] years of dedicated service in the dye industry, we have cultivated enduring partnerships with major textile groups and denim manufacturers worldwide. Our internal R&D capabilities, coupled with collaborations with academic institutions, ensure we remain at the forefront of dye technology and sustainable production. Regular audits by third-party certification bodies and major clients reinforce our operational excellence. Our comprehensive test data and batch analysis reports are available upon request, providing transparent insights into our product performance.

Image 4: Quality control and testing at our light indigo color company.

Trustworthiness, FAQs, and Customer Support

Building trust is paramount in B2B relationships. Our transparent processes, clear commitments, and robust customer support infrastructure underpin our reliability as a light indigo color company.

Frequently Asked Questions (FAQs):

- Q: What forms of Indigo Blue Vat Blue do you offer?

- A: We primarily offer Indigo Blue Vat Blue in powder (micronized) and granular forms to suit various customer application requirements. Specific grades for different industries are available.

- Q: How does your light indigo color pricelist compare to competitors?

- A: Our pricing reflects the premium quality, high purity, and comprehensive technical support that accompanies our products. While we maintain competitive pricing, our focus is on delivering superior value through product consistency and reliability, minimizing long-term operational costs for our clients. We encourage inquiries for detailed quotations.

- Q: What are your typical lead times for large orders?

- A: For standard Indigo Blue Vat Blue orders, our typical lead time ranges from 2-4 weeks, depending on order size and destination. For customized solutions or very large volumes from our light indigo color factory, lead times will be confirmed at the time of order based on production schedules.

- Q: Do you provide samples for testing?

- A: Yes, we provide samples of our Indigo Blue Vat Blue for clients to conduct their own quality and compatibility tests. Please contact our sales team to arrange sample delivery.

- Q: What are the environmental considerations for your light indigo color products?

- A: Our manufacturing processes at our light indigo color factories are designed for minimal environmental impact, adhering to ISO 14001, REACH, and OEKO-TEX standards. We continuously invest in technologies that reduce waste, conserve water, and minimize energy consumption.

Lead Time & Fulfillment Details:

Our global distribution network and efficient production capabilities at our light indigo color factory enable us to provide consistent and timely fulfillment. Standard orders are typically processed and shipped within 10-14 business days, with transit times varying by destination. Urgent orders and customized solutions are managed with expedited planning, ensuring critical supply chain needs are met. Our logistics team works closely with clients to manage shipping preferences and customs requirements.

Warranty Commitments:

We offer a comprehensive product warranty guaranteeing that our Indigo Blue Vat Blue meets all published specifications and is free from manufacturing defects for a period of 12 months from the date of shipment, provided it is stored and handled according to our recommendations. Our commitment extends to providing batch-specific Certificates of Analysis for every delivery.

Dedicated Customer Support:

Our customer support team is available from Monday to Friday, 9:00 AM to 5:00 PM (GMT+8). We provide multi-channel support via phone, email, and a dedicated online portal. For technical inquiries, our experienced chemists and application specialists are ready to assist with troubleshooting, process optimization, and product selection for any specific industrial challenge related to light indigo color service.

Conclusion

The demand for high-quality light indigo color continues to be a cornerstone of the global textile industry, particularly for denim. As a specialized light indigo color company, our commitment extends beyond merely supplying a product; we offer a complete partnership built on expertise, proven experience, authoritative certifications, and unwavering trustworthiness. Through advanced manufacturing processes, rigorous quality control, and a customer-centric approach, our Indigo Blue Vat Blue products consistently deliver superior performance, aesthetic appeal, and environmental responsibility. We invite B2B decision-makers and technical teams to explore the distinct advantages of partnering with us for their light indigo color requirements, ensuring consistent quality and innovation for their supply chain.

References

- Society of Dyers and Colourists. "The Colour Index™." Published by SDC and AATCC.

- International Organization for Standardization (ISO). "ISO 9001:2015 Quality management systems — Requirements."

- International Organization for Standardization (ISO). "ISO 14001:2015 Environmental management systems — Requirements with guidance for use."

- European Chemicals Agency (ECHA). "REACH Regulation (EC) No 1907/2006."

- OEKO-TEX®. "STANDARD 100 by OEKO-TEX®."

- Choudhury, A. K. R. (2006). "Textile Preparation and Dyeing." Science Publishers.

- Shenai, V. A. (1995). "Chemistry of Dyes and Principles of Dyeing." Colour Publications.

-

Innovating Bromo Indigo Excellence

NewsAug.23,2025

-

Pioneering Indigo Plant Dye Excellence

NewsAug.23,2025

-

Leading Sulphur Black Dyes Enterprise

NewsAug.23,2025

-

Sulphur Black Dyes Light Resistance

NewsAug.23,2025

-

Indigo Blue Granular Industrial Uses

NewsAug.23,2025

-

Bromo Indigo Synthetic Production Process

NewsAug.23,2025

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

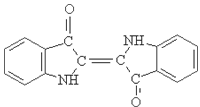

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.