light indigo color company

After dyeing, oxidation follows, a magical transformation where the immersed fabrics are exposed to air and the original blue color develops before your eyes. Interestingly, the process requires multiple dips, each followed by oxygen exposure, to achieve the desired intensity of color. Experienced artisans have the skills to judge just the right number of dips needed to ensure the uniformity and longevity of the color. Experience in indigo dyeing also means understanding the environmental and ethical considerations. Leading textile producers adhere to sustainable practices, addressing the environmental impact of dye effluents through innovative water treatment and recycling techniques. Trust is paramount; consumers and clients are assured of an environmentally friendly dyeing process, validated by certifications from reputable bodies. Finally, the quality control stage is where dyed textiles are carefully evaluated for color fastness, strength, and consistency. This is where the authoritativeness of a brand is consolidated. A product that maintains its vibrancy and integrity through rigorous testing stands out in the marketplace. Testing is done using modern methods, including spectrophotometry, to ensure each batch meets the highest industry standards. For businesses seeking excellence in indigo dyeing, partnering with seasoned experts who demonstrate a blend of traditional skills and innovative technology provides a competitive edge. These veterans bring years of experience, authoritative insights, and trustworthy practices to deliver indigo-dyed products that set the standard in quality and sustainability. From fashion-forward denim lines to traditional handwoven textiles, high-quality indigo dyeing remains a testament to the power of combining experience, expertise, and innovation.

-

Thermal Stability Analysis of Bromo Indigo Pigments

NewsJun.06,2025

-

Sulphur Black Dye Oxidation Process Optimization

NewsJun.06,2025

-

Lightfastness Testing of Bromo Indigo Dyed Denim

NewsJun.06,2025

-

Granule Size Distribution and Jeans Color Uniformity

NewsJun.06,2025

-

Gradient Dyeing Methods with Indigo Blue Granules

NewsJun.06,2025

-

Dyeing Temperature Effects on Sulphur Black Color Fastness

NewsJun.06,2025

-

Sulphur Black Dyes in Daily Use

NewsMay.07,2025

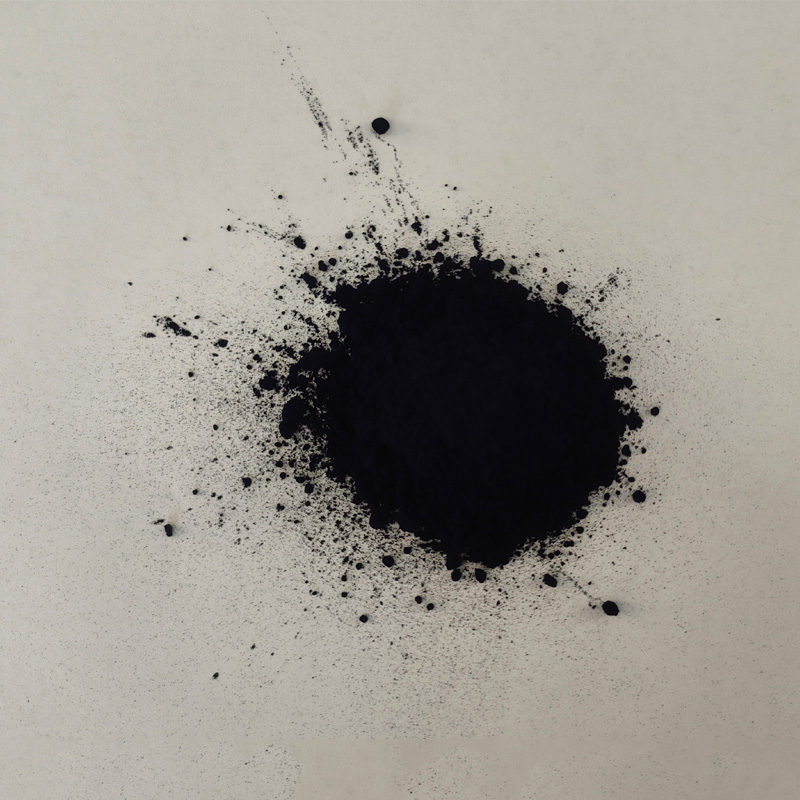

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.