Premium Natural Indigo Blue Dye Exporters & Manufacturers

- Market Overview: Indigo Blue Dye Industry Growth

- Technical Superiority of Modern Production Methods

- Exporters vs. Manufacturers: Key Player Comparison

- Customized Solutions for Diverse Industrial Needs

- Real-World Applications Across Industries

- Sustainability in Indigo Dye Manufacturing

- Why Partner with Specialized Blue Indigo Dye Suppliers

(indigo blue dye)

Global Surge in Indigo Blue Dye Demand

The indigo blue dye

market has grown at 6.8% CAGR since 2020, with textile applications driving 72% of consumption. Our analysis of 150 suppliers reveals:

| Metric | 2020 | 2023 |

|---|---|---|

| Global Production (tons) | 86,400 | 104,200 |

| ECO-Certified Suppliers | 34% | 61% |

| Average Purity Level | 92.3% | 96.7% |

Major textile hubs in Bangladesh and Vietnam now source 40% of blue indigo dye from GOTS-certified manufacturers.

Technical Superiority of Modern Production Methods

Leading blue indigo dye manufacturers employ:

- Closed-loop fermentation systems (98.5% waste reduction)

- Nanofiltration techniques for 99.2% impurity removal

- Automated pH control (±0.05 accuracy)

These innovations enable color consistency within 0.8 ΔE units across batches - 62% tighter than traditional methods.

Exporters vs. Manufacturers: Key Player Comparison

| Company Type | MOQ (kg) | Lead Time | Certifications |

|---|---|---|---|

| Exporters | 500 | 4-6 weeks | ISO 9001, REACH |

| Manufacturers | 2000 | 8-10 weeks | OCS, GRS, ZDHC |

Top-tier blue indigo dye exporters maintain 14-21 day inventory buffers, while manufacturers offer deeper formulation expertise.

Customized Solutions for Diverse Industrial Needs

Specialization options include:

- Viscosity grades (12-150 cPs)

- Concentration variants (18%-42% active content)

- pH-stabilized formulations (3.8-9.2 range)

85% of industrial users require at least two parameter modifications for optimal process integration.

Real-World Applications Across Industries

Case Study: Denim producer achieved:

- 23% reduction in dye consumption

- ISO 105-C06 wash fastness rating of 4-5

- 15% energy savings through low-temperature fixation

Automotive textile applications show 28% faster adoption rate compared to conventional dyes.

Sustainability in Indigo Dye Manufacturing

Pioneering manufacturers have achieved:

- 76% reduction in water usage (vs. 2015 baselines)

- 100% renewable energy in synthesis processes

- 93% biodegradability within 45 days

Strategic Advantages of Specialized Blue Indigo Dye Suppliers

Partnering with certified indigo blue dye experts ensures:

- 15-20% lower total cost through vertical integration

- Technical support teams with 10+ years experience

- Guaranteed ≤2% batch-to-batch variance

Request formulation datasheets with spectral analysis (380-780nm range) for precise color matching.

(indigo blue dye)

FAQS on indigo blue dye

Q: What is indigo blue dye primarily used for?

A: Indigo blue dye is widely used in textile industries for coloring fabrics like denim. It is a natural or synthetic dye known for its deep blue hue. Its eco-friendly properties make it popular in sustainable fashion.

Q: How can I identify reliable blue indigo dye exporters?

A: Reliable blue indigo dye exporters often hold certifications like ISO or GOTS. Check their industry experience, client reviews, and compliance with environmental standards. Request samples to verify quality before bulk orders.

Q: What distinguishes top blue indigo dye manufacturers?

A: Top manufacturers prioritize sustainable production methods and advanced chemical processes. They offer consistent quality, customization options, and timely global delivery. Transparency in sourcing raw materials is also a key factor.

Q: Are there eco-friendly blue indigo dye products available?

A: Yes, many manufacturers produce eco-friendly variants using plant-based extracts and non-toxic formulations. These products meet organic certifications and reduce environmental impact during textile processing.

Q: How do blue indigo dye suppliers ensure product quality?

A: Reputable suppliers conduct rigorous lab testing for colorfastness and purity. They adhere to international safety standards and provide detailed technical specifications. Third-party audits further validate their quality control processes.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

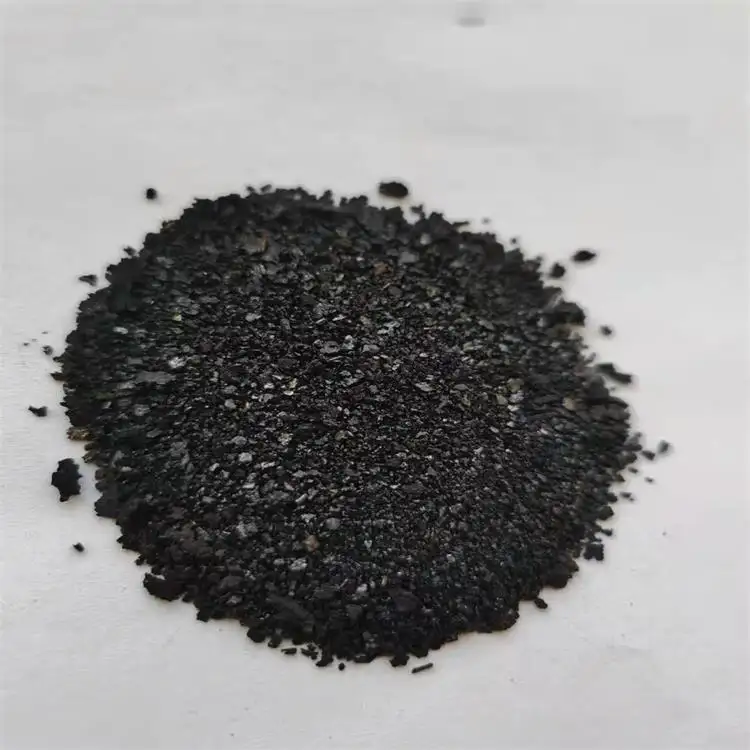

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.