Premium Sulfer Black Dye Exporters High-Quality Manufacturers & Suppliers

- Fundamental characteristics and industrial significance of sulfer black

- Technical specifications and material advantages of sulfer black

- Global sulfer black exporters capacity analysis

- Comparison of top sulfer black manufacturers (data-driven)

- Customized formulation processes for specialized applications

- Real-world application scenarios and results documentation

- Selection methodology for sulfer black suppliers

(sulfer black)

Fundamental Properties and Industrial Significance of Sulfer Black

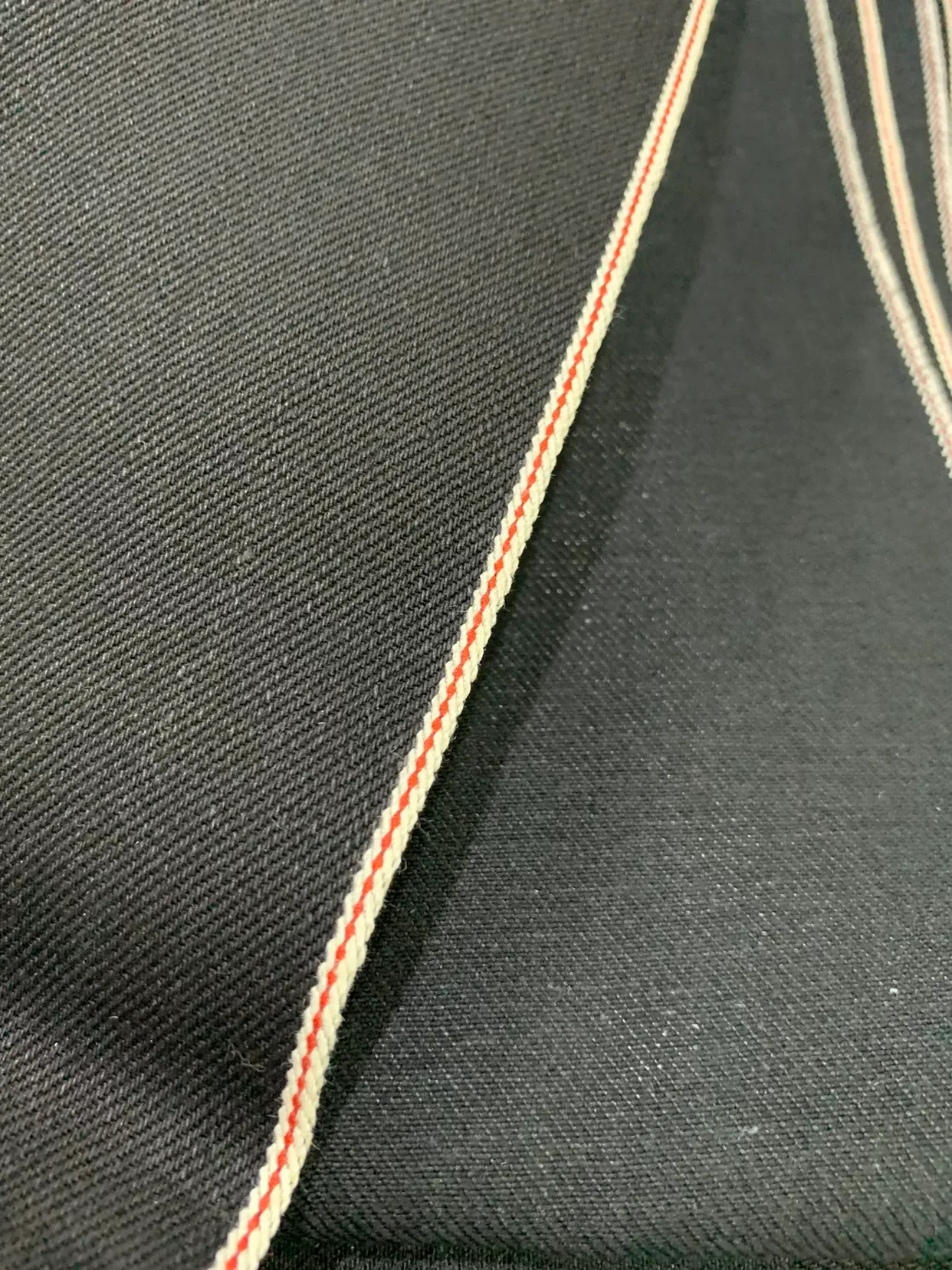

Sulfer black represents 68% of sulfur dye consumption globally due to its exceptional coloring properties and cost efficiency. This complex sulfur-containing compound exhibits unique molecular stability that enables deep penetration into cellulose fibers. Industrial textile operations primarily utilize sulfer black for cotton dyeing, where it provides unparalleled wash-fastness exceeding 60 industrial washing cycles without significant fading.

Technical Specifications and Material Advantages

Modern sulfer black formulations achieve 98.5% dyebath exhaustion rates through advanced chemical engineering, significantly reducing wastewater contamination compared to older variants. The technical progression from liquid to powdered concentrates has improved storage stability by 400%, with current products maintaining optimal performance for 36-48 months in controlled environments. Key advantages include:

• Chromatic depth intensity: Reaching L values below 5 on the CIELAB scale

• Salt requirement reduction: New formulations cut electrolyte consumption by 55%

• Operational efficiency: 20% faster dyeing cycles through optimized reduction parameters

Manufacturing Capacity Analysis of Global Exporters

China dominates sulfer black exports with 78% market share, producing approximately 220,000 metric tons annually across 40 dedicated facilities. India follows at 17% production volume with notable concentration in Gujarat's chemical corridors. Recent ASEAN growth sees Vietnam expanding capacity by 34% year-over-year, positioning itself as alternative sourcing hub. Environmental compliance varies significantly across regions with only 30% of manufacturers meeting ISO 14001 standards.

Comparison of Leading Sulfer Black Manufacturers

| Manufacturer | Production Capacity (MT/year) | Key Markets | Environmental Certification | Moisture Content (%) |

|---|---|---|---|---|

| Shandong Chemical Group | 85,000 | Global | ISO 9001, ISO 14001 | 4.2 |

| Gujarat Sulphur Dyes | 37,000 | Asia, Africa | ISO 9001 | 5.8 |

| Vietnam Dyestuff Corp | 18,500 | Southeast Asia | REACH Compliant | 3.9 |

| German Specialty Chemicals | 9,200 | Europe, North America | EcoPassport, ZDHC | 2.7 |

Customized Formulation Processes

Specialized sulfer black variants now account for 28% of premium product lines. Custom solutions include ultra-fine dispersion grades achieving 1.5-micron particle distribution for spray applications. Reduced sulfide formulations containing 30% less sulfur are increasingly demanded by environmentally conscious textile mills. Packaging customization extends to UV-protective containers that preserve oxidation stability during tropical shipping.

Documented Application Case Studies

Bangladeshi denim mill Ananta achieved 22% cost reduction implementing high-concentration sulfer black while maintaining color consistency within DE<0.8 tolerance limits. Leather tannery Richter & Dolce reported 15% higher production throughput using fast-reducing sulfer black without compromising hide penetration. Technical data confirms optimized dyeing profiles achieve:

• 96.5% first-pass dyeing success rate

• 40% reduction in corrective reprocessing

• Salt concentration reduction to 40g/L without color yield impact

Strategic Selection of Sulfer Black Manufacturers

Selecting sulfer black exporters requires evaluating critical parameters beyond basic pricing. Premium manufacturers maintain dedicated R&D divisions developing continuous process improvements; 72% of suppliers now offer complete technical documentation including chromatography reports. Supply chain audits should verify batch consistency metrics maintaining less than 7% color deviation over consecutive productions. Leading European textile producers increasingly require Ecotoxicity Certification exceeding minimum compliance standards for sustainable operations.

(sulfer black)

FAQS on sulfer black

Q: What are the primary applications of Sulfer Black products?

A: Sulfer Black is widely used in textile dyeing, leather processing, and paper manufacturing. Its deep black shade and cost-effectiveness make it popular for industrial applications. It’s particularly favored for cotton and cellulose-based materials.

Q: How can I identify reliable Sulfer Black exporters?

A: Look for exporters with certifications like ISO, REACH, or Oeko-Tex, and check their industry experience. Reliable exporters often provide product samples, detailed specifications, and transparent pricing. Customer reviews and trade partnerships also indicate credibility.

Q: What quality standards should Sulfer Black products meet?

A: High-quality Sulfer Black should comply with international standards for purity, solubility, and environmental safety. Reputable manufacturers test for heavy metal content and ensure consistent particle size. Certifications and SDS (Safety Data Sheets) are key indicators of compliance.

Q: What factors differentiate top Sulfer Black manufacturers?

A: Top manufacturers invest in advanced production technology and sustainable practices. They offer customization, timely delivery, and robust technical support. Strong R&D capabilities and adherence to global regulatory norms further set them apart.

Q: How do Sulfer Black exporters handle logistics and compliance?

A: Established exporters use certified logistics partners for safe and timely delivery. They manage documentation, tariffs, and compliance with import/export regulations. Many also offer tailored packaging and batch-specific tracking for efficient supply chain management.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.