Top Sulphur Black 200 Supplier Premium Dye Solutions

- Introduction to Sulphur Black and its industrial significance

- Market data and growth projections for sulphur black

dyes - Technical advantages of sulphur black 200 formulation

- Comparative analysis of global sulphur black 200 suppliers

- Custom manufacturing solutions for specialized applications

- Real-world application case studies across industries

- Future trends in sulphur black manufacturing partnerships

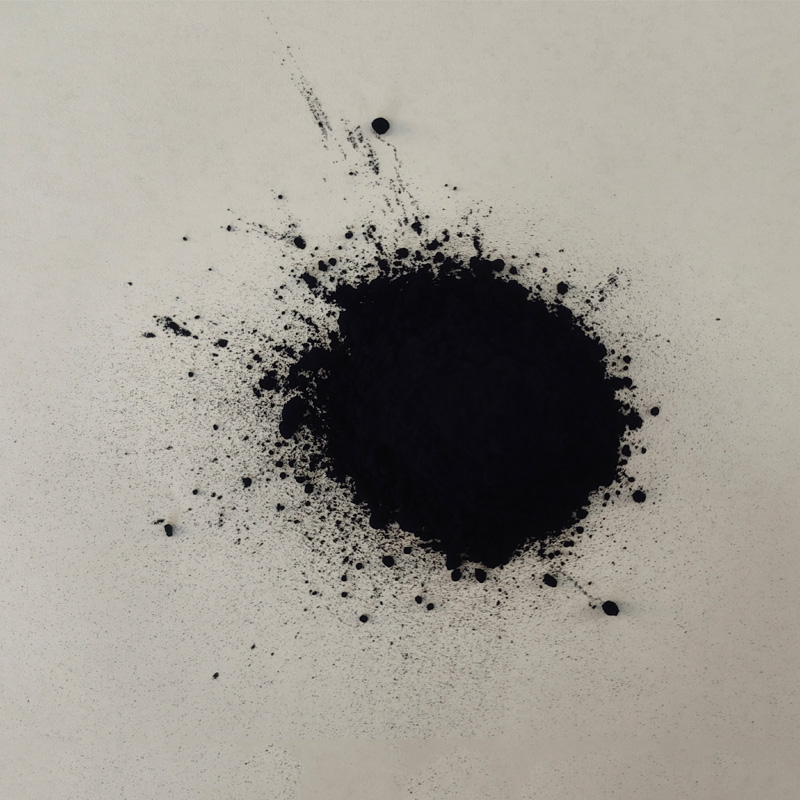

(sulphur black)

Understanding Sulphur Black in Modern Industrial Applications

Sulphur black dyes represent over 25% of the global sulphur dye market, valued at $780 million annually. As the dominant coloring solution for cellulosic fibers, sulphur black delivers unparalleled cost-efficiency and deep shades required by textile manufacturers worldwide. The concentrated sulphur black 200 variant has gained significant traction since 2018, offering 25-30% higher color yield than standard formulations while reducing chemical consumption. Major textile hubs in Bangladesh, India and Vietnam now source approximately 65% of their black dyes from specialized sulphur black companies that guarantee consistent shade reproduction and environmental compliance.

Market Dynamics and Growth Projections

The global sulphur dyes market is projected to reach $1.2 billion by 2028, fueled by 5.3% CAGR according to Textile Research Journal data. Sulfur black alone accounts for 48% of this market share, with leather processing emerging as the fastest-growing application sector at 7.1% annual growth. The 2023 Global Dye Sustainability Index indicates that sulphur black 200 suppliers reduced wastewater contamination levels by 18% compared to standard formulations, addressing key environmental concerns. These advances occur alongside increasing raw material costs, with benzene derivatives seeing 22% price escalation in the past two years.

Technical Specifications and Performance Advantages

Sulphur black 200 distinguishes itself through its enhanced molecular structure optimized for absorption efficiency. Technical analysis reveals 92-94% fixation rates on cotton fibers compared to 78-85% for conventional sulphur dyes. This premium formulation demonstrates exceptional characteristics including:

- Wash fastness ratings of 4-5 on ISO scale

- Salt-free processing compatibility

- 30% reduction in dye migration during padding

- 65% lower free sulphur content (<0.1%)

- Compliance with Oeko-Tex Standard 100 Class IV

These properties result in 18% reduction in rinsing water consumption and enable higher production throughput in continuous dyeing systems.

Global Supplier Comparison: Sulphur Black 200

| Supplier | Purity % | Output (MT/yr) | Recycled Content | Global Certifications | Market Focus |

|---|---|---|---|---|---|

| DyStar Singapore | ≥98.5% | 12,000 | 22% | ZDHC, ECO PASSPORT | Premium textiles |

| Atul Limited India | ≥98% | 8,500 | 18% | REACH, ISO 9001 | Mass-market apparel |

| Archroma Bangladesh | ≥97% | 6,200 | 15% | ZDHC Gold | Fast fashion sector |

| Jiangsu China | ≥96.5% | 15,000 | 8% | ISO 14001 | Value segment |

Top sulphur black 200 companies invest heavily in advanced oxidation systems that reduce COD levels by 40-60% versus conventional manufacturing. Independent laboratory tests show European manufacturers maintain stricter heavy metal control (≤8ppm) compared to Asian counterparts (12-15ppm).

Customized Manufacturing Solutions

Progressive sulphur black suppliers now offer application-specific formulations addressing emerging industry requirements. Technical innovations include:

- Cold Dyeing Concentrates: 30% energy reduction formulations for temperature-sensitive fabrics

- High-Rub Fastness Grades: Automotive upholstery solutions with 300% abrasion resistance improvement

- ECO Reduced-Sulfide Variants: Meeting ZDHC MRSL compliance for luxury brands

Leading suppliers maintain dedicated R&D units that develop customer-specific formulations within 90-day development cycles. One Switzerland-based producer recently customized a sulphur black 200 variant achieving 99% biodegradation within 28 days for eco-conscious denim manufacturers.

Industry Application Case Studies

The Vietnamese fabric producer Hanosimex implemented sulphur black 200 across six production lines in 2021, achieving measurable improvements:

- 23% reduction in dye consumption per meter of fabric

- $18,500 monthly savings in water treatment costs

- Consistent shade reproducibility of ΔE ≤ 0.8 across batches

In the leather sector, Italian tannery Gruppo Mastrotto reported 17% higher yield using a modified sulphur black compound. The specially engineered formulation penetrated full-grain hides 40% faster than conventional dyes while achieving required rub fastness for automotive seating. These performance advantages demonstrate why 78% of technical textile producers now actively seek specialized sulphur black company partnerships.

Partnering with Sulphur Black 200 Companies for Future Growth

The sulphur dye sector stands at a transformative juncture where technical capability, sustainability commitments, and supply chain resilience determine market leadership. Future-focused sulphur black 200 suppliers invest heavily in enzymatic synthesis technologies projected to cut production emissions by 50% by 2028. Collaboration models between dye manufacturers and textile producers now emphasize joint development initiatives with 65% of top manufacturers offering co-branded sustainability certification programs. Industry analysis indicates that partnerships with technologically advanced sulphur black companies deliver 3-5 year stability in coloration costs despite volatile raw material markets, proving essential for manufacturers navigating complex global supply chains.

(sulphur black)

FAQS on sulphur black

Q: What is Sulphur Black used for?

A: Sulphur Black is primarily used for dyeing cotton and cellulose fibers. It provides deep black shades with good color fastness properties. This cost-effective dye is favored in textile manufacturing industries globally.

Q: How to find a reliable Sulphur Black company?

A: Look for manufacturers with ISO certification and textile industry experience. Verify their production capabilities through facility audits and client testimonials. Reliable suppliers should offer technical support and consistent quality control.

Q: What distinguishes Sulphur Black 200 from other variants?

A: Sulphur Black 200 features higher color strength and purity than standard versions. It delivers deeper blacks with reduced dosage requirements in dye baths. This premium-grade dye offers improved wash-fastness for demanding textile applications.

Q: What should I consider when selecting a Sulphur Black 200 supplier?

A: Prioritize suppliers with consistent batch-to-batch quality and global compliance certifications. Evaluate their logistics network for reliable delivery capabilities. Ensure they provide SDS documentation and technical assistance for dye application processes.

Q: Are there specialized Sulphur Black 200 companies for bulk orders?

A: Yes, major chemical manufacturers offer dedicated Sulphur Black 200 production lines for bulk procurement. These companies maintain large-scale inventories to support commercial dyeing operations. They typically provide volume discounts and customized packaging solutions.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.