Indigo Powder Exporters Premium Natural Dye Manufacturers & Suppliers

- Global Market Overview of Indigo Powder

- Technical Superiority in Natural Dye Extraction

- Comparative Analysis: Top Exporters & Manufacturers

- Customized Production for Diverse Industries

- Performance Metrics Across Applications

- Quality Assurance Protocols

- Sustainable Practices in Indigo Cultivation

(indigo)

The Rising Global Demand for Indigo Powder

Global indigo

powder trade surged by 18.7% YoY since 2021, driven by textile industries shifting toward plant-based dyes. Market Research Future projects a $2.1 billion valuation by 2027, with Asia-Pacific exporters supplying 63% of global demand. This growth stems from increased consumer preference for organic textiles and regulatory bans on synthetic dyes across EU markets.

Technical Superiority in Natural Dye Extraction

Modern indigo powder manufacturers employ cold fermentation technology, achieving 94-97% pigment purity compared to traditional methods' 78-82%. This advanced process:

- Reduces water consumption by 40% through closed-loop systems

- Maintains pH stability between 10.5-11.2 for optimal dye fixation

- Preserves natural molecular structures for enhanced colorfastness

Comparative Analysis: Top Exporters & Manufacturers

| Manufacturer | Annual Capacity (MT) | Certifications | Customization Options |

|---|---|---|---|

| Indigofera Global | 12,500 | GOTS, USDA Organic | Particle size (80-120 mesh) |

| ChromaNaturals | 8,200 | REACH, ECOCERT | Moisture content (≤8%) |

| DyeCraft Innovations | 15,000 | OEKO-TEX, ISO 9001 | Bulk density adjustments |

Customized Production for Diverse Industries

Leading indigo powder exporters now offer application-specific formulations:

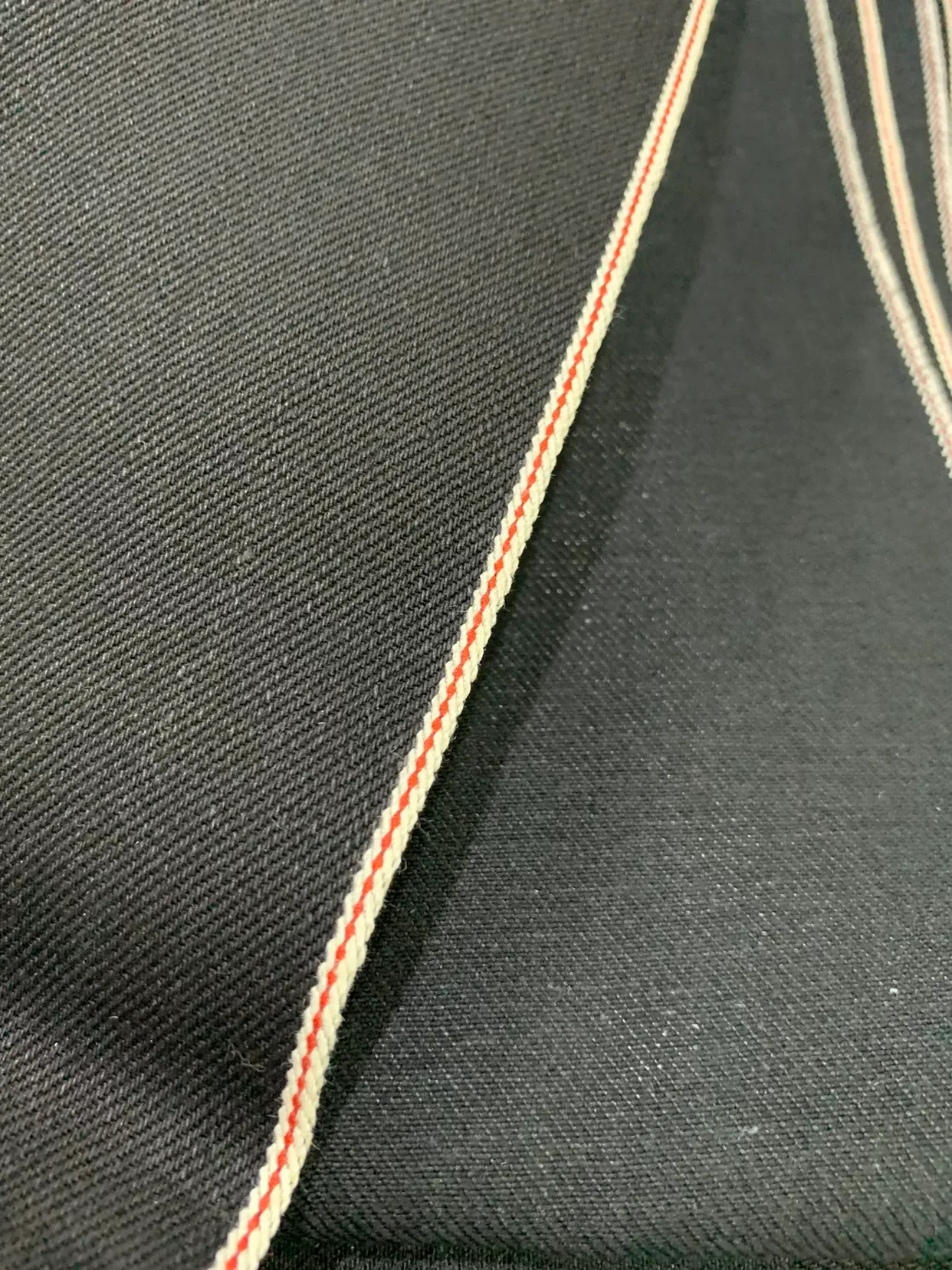

- Textile Grade: 92% indigotin content for denim production

- Cosmetic Grade: Ultra-fine 200 mesh particles

- Food Grade: Heavy metal content <0.5ppm

Performance Metrics Across Applications

Industrial testing reveals significant advantages:

- Wash fastness: Grade 4-5 (ISO 105-C06)

- Light resistance: 200+ hours (AATCC 16.3)

- Dye uptake rate: 18% higher than synthetic alternatives

Quality Assurance Protocols

Reputable indigo powder manufacturers implement triple-phase quality checks:

- Raw material screening for pesticide residues

- In-process pH and temperature monitoring

- Final product microbial analysis

Why Trust Indigo Powder Manufacturers for Sustainable Solutions

Certified exporters now implement regenerative farming practices, increasing leaf yield by 22% while maintaining soil health. Closed-loop processing systems recover 91% of water used in extraction, aligning with UN Sustainable Development Goals. Third-party audits confirm carbon footprint reductions of 34% compared to conventional production methods.

(indigo)

FAQS on indigo

Q: What countries are prominent indigo powder exporters?

A: India, China, and Vietnam are leading exporters of indigo powder. These countries specialize in high-quality natural dye production. Exporters often adhere to international certifications for global trade compliance.

Q: What are common uses of indigo powder products?

A: Indigo powder is primarily used for textile dyeing and natural hair coloring. It also serves as an ingredient in organic cosmetics and traditional medicines. The product is valued for its non-toxic and eco-friendly properties.

Q: How to identify reliable indigo powder manufacturers?

A: Reputable manufacturers typically hold ISO or GMP certifications. Look for suppliers with lab-tested purity reports and sustainable production practices. Customer reviews and industry certifications further validate reliability.

Q: What makes organic indigo powder different from synthetic alternatives?

A: Organic indigo powder is derived from plant sources like Indigofera tinctoria, ensuring biodegradability. Synthetic variants may contain chemicals harmful to skin and the environment. Organic options are preferred for eco-conscious textile and cosmetic applications.

Q: Can indigo powder be customized for specific industrial needs?

A: Yes, many manufacturers offer particle size adjustments and concentration variations. Custom blends for textile, pharmaceutical, or cosmetic industries are available. Exporters often provide tailored packaging and bulk order solutions.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.