light indigo color company

Resist techniques such as shibori can add intricate patterns to your fabrics. This involves folding, twisting, and binding the fabric in various ways to achieve desired designs. Each technique creates unique patterns that are characteristic of this art form, making each piece truly one-of-a-kind. Experimenting with different methods provides an opportunity to develop a personalized style, contributing to the uniqueness of DIY indigo products. Immersing the fabric is where the magic happens. Fabrics are dipped into the vat, and upon exposure to air, the oxidation process turns the dyed sections into the classic indigo blue. Repeated dipping can deepen the color, but care should be taken to let the fabric oxidize fully between dips. This step requires patience and precision but ensures a profound richness in the final color. Once the desired shade is achieved, a thorough rinse removes excess dye, followed by a fixative to set the colors, ensuring they remain vibrant through use and washing. This step enhances the durability of the finished product, establishing trust with users who value long-lasting items. Producing an indigo-dyed product is an art that blends creativity with a deep respect for historical methods. By adhering to responsible practices and emphasizing quality, it is possible to make items that inspire and last. Whether fashioning a piece of clothing, home decor, or accessories, DIY indigo dyeing embodies an expertise that connects the past with contemporary style, offering a unique, authoritative presence in any setting.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

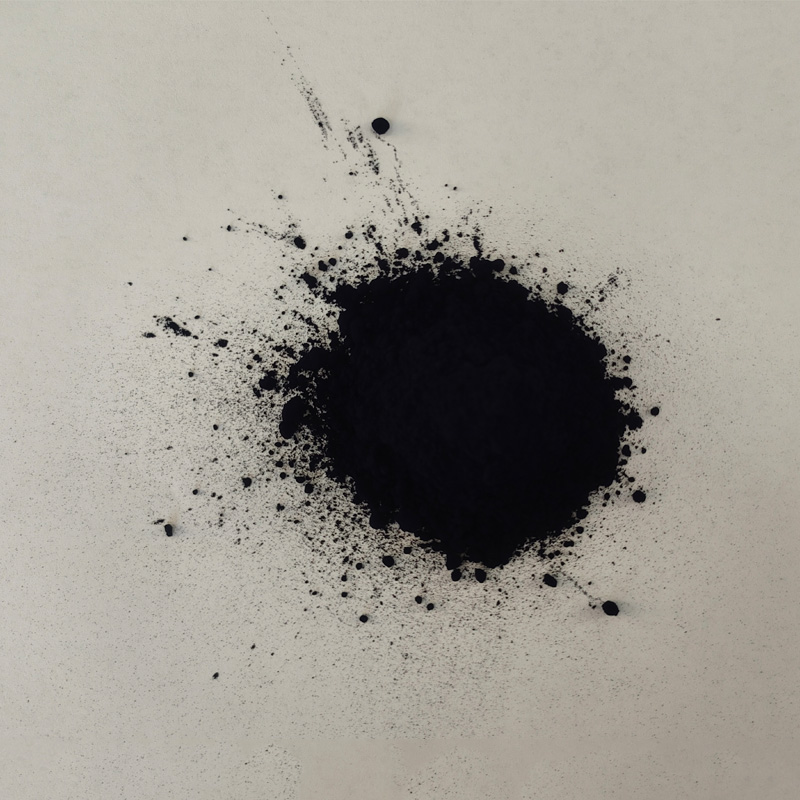

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.