Advanced High-Quality Sulfur Dyeing Techniques for Enhanced Textile Coloration

One of the key advantages of high-quality sulfur dyeing is its ability to create a wide range of shades, from soft pastels to deep, intense hues

One of the key advantages of high-quality sulfur dyeing is its ability to create a wide range of shades, from soft pastels to deep, intense hues

One of the key advantages of high-quality sulfur dyeing is its ability to create a wide range of shades, from soft pastels to deep, intense hues

One of the key advantages of high-quality sulfur dyeing is its ability to create a wide range of shades, from soft pastels to deep, intense hues high quality sulphur dyeing. The color palette is versatile, allowing for endless design possibilities. Moreover, the process is eco-friendly due to its lower energy consumption and minimal waste production compared to other dyeing methods.

However, achieving high-quality sulfur dyeing is not just about the process; it's also about the quality of the dye itself. The best sulfur dyes are carefully formulated, ensuring consistent performance and color yield. They are free from impurities that could lead to uneven coloring or reduced colorfastness. Regular quality checks and stringent manufacturing standards guarantee the reliability and excellence of the final product.

In conclusion, high-quality sulfur dyeing is a testament to the textile industry's commitment to aesthetics, functionality, and sustainability. It combines traditional knowledge with modern techniques, resulting in fabrics that not only look beautiful but also stand the test of time. Whether it's a piece of clothing, a home textile, or an industrial application, sulfur dyeing continues to play a vital role in creating products that are both visually appealing and robust. As technology advances, one can expect even higher standards of quality and efficiency in this age-old dyeing method.

high quality sulphur dyeing. The color palette is versatile, allowing for endless design possibilities. Moreover, the process is eco-friendly due to its lower energy consumption and minimal waste production compared to other dyeing methods.

However, achieving high-quality sulfur dyeing is not just about the process; it's also about the quality of the dye itself. The best sulfur dyes are carefully formulated, ensuring consistent performance and color yield. They are free from impurities that could lead to uneven coloring or reduced colorfastness. Regular quality checks and stringent manufacturing standards guarantee the reliability and excellence of the final product.

In conclusion, high-quality sulfur dyeing is a testament to the textile industry's commitment to aesthetics, functionality, and sustainability. It combines traditional knowledge with modern techniques, resulting in fabrics that not only look beautiful but also stand the test of time. Whether it's a piece of clothing, a home textile, or an industrial application, sulfur dyeing continues to play a vital role in creating products that are both visually appealing and robust. As technology advances, one can expect even higher standards of quality and efficiency in this age-old dyeing method. -

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

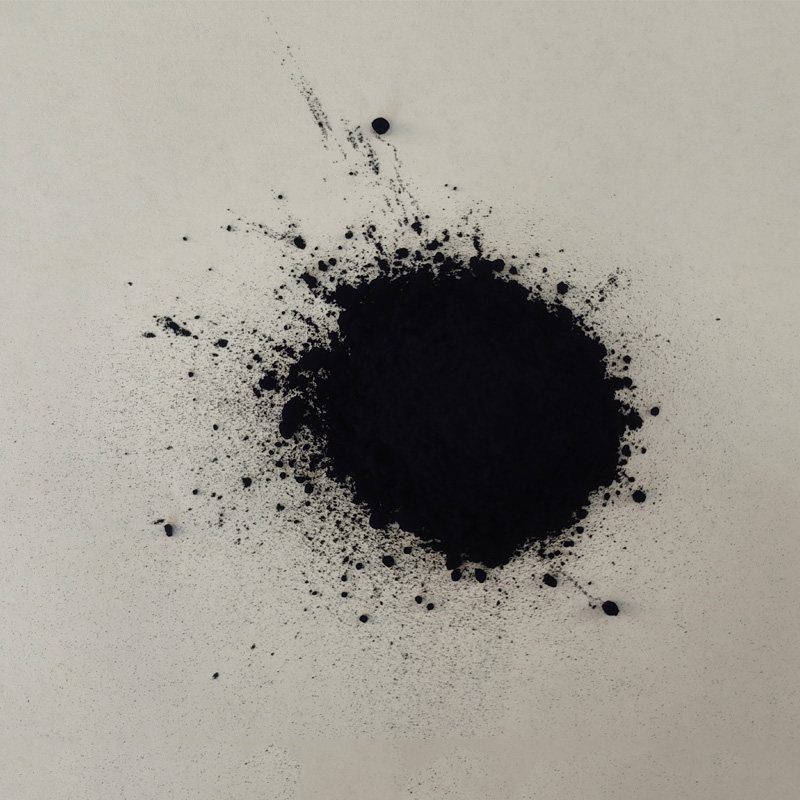

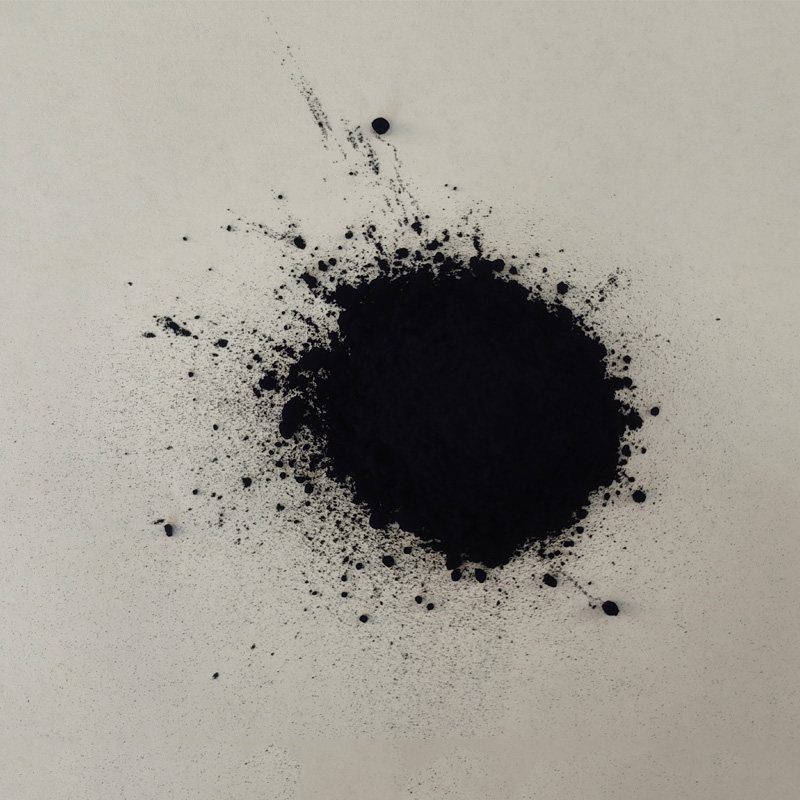

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.