Bromo Indigo Powder Manufacturing Facilities and Their Production Processes Explained

The Rise of Bromo Indigo Powder Factories A Colorful Revolution

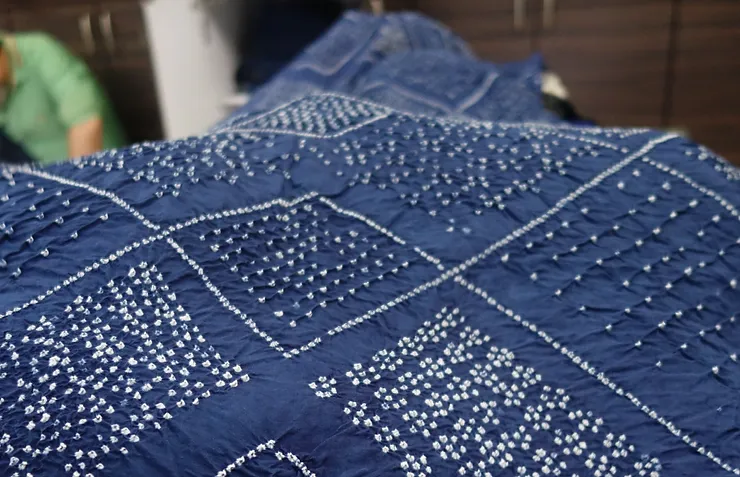

In recent years, the textile industry has witnessed a remarkable transformation with the rise of innovative techniques and sustainable practices. Among these advancements, the production of bromo indigo powder has emerged as a significant player in dye manufacturing, captivating the interest of manufacturers and consumers alike. Bromo indigo, a synthetic dye, has established itself as a vital component in creating vibrant hues for cotton and other textiles, leading to the development of specialized factories dedicated to its production.

Bromo indigo, derived from natural indigo, offers several advantages that make it a preferred choice among textile companies. One key benefit is its remarkable colorfastness. Unlike traditional dyes that may fade or wash out over time, bromo indigo maintains its vibrant blue hues even after repeated laundering. This characteristic is particularly appealing to consumers who seek durable and long-lasting clothing. As fashion trends evolve, the demand for reliable dyes has surged, and bromo indigo's resilience has positioned it as a frontrunner in the market.

The synthesis of bromo indigo involves a chemical reaction that enhances the natural properties of indigo, resulting in a dye that is not only more intense in color but also easier to use during the dyeing process. Factories specializing in bromo indigo powder production have emerged globally, utilizing advanced technology and innovative methodologies to streamline operations and increase efficiency. These factories often employ skilled chemists and technicians who work diligently to perfect the production process, ensuring high-quality output that meets market demands.

bromo indigo powder factories

Environmental concerns have also played a significant role in the rise of bromo indigo powder factories. As the textile industry faces scrutiny for its environmental impact, many manufacturers are turning to bromo indigo as a more sustainable alternative. The production of synthetic dyes is generally less water-intensive than that of natural dyes, which often require extensive irrigation. Additionally, bromo indigo can be produced in controlled environments, reducing the risk of pollution associated with traditional dyeing methods. Factories that prioritize sustainable practices are increasingly favored by eco-conscious consumers, driving further growth in the sector.

Moreover, the globalization of trade has expanded the reach and influence of bromo indigo powder factories. As the demand for high-quality textiles rises in various regions, manufacturers are recognizing the importance of sourcing reliable and vibrant dyes. Partnerships between factories and textile companies have flourished, creating a collaborative ecosystem that fosters innovation and quality assurance. This synergy has not only improved product offerings but also stimulated local economies by providing job opportunities in the dye manufacturing sector.

The future of bromo indigo powder factories looks promising, with ongoing research and development aimed at enhancing dye properties and production methods. Innovations in eco-friendly production techniques, such as water recycling systems and bio-based solvents, are under investigation to further minimize environmental impact. Emerging technologies, like computer-aided dyeing processes, are set to revolutionize the way dyes are applied to textiles, making the entire process more efficient and cost-effective.

In conclusion, the emergence of bromo indigo powder factories signifies a pivotal moment in the textile industry. With their ability to produce vibrant, durable, and environmentally friendly dyes, these factories play a crucial role in shaping modern fashion. As consumer preferences shift towards sustainable and high-quality products, the demand for bromo indigo is expected to grow, solidifying its position as a staple in dye manufacturing. The colorful revolution brought about by bromo indigo is not just a trend; it is a testament to the industry’s commitment to innovation, sustainability, and quality.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.