Comprehensive Guide to Safety Data Sheets for Sulphur Black Manufacturers and Usage Considerations

Understanding Sulphur Black Safety and Compliance with MSDS

Introduction

Sulphur black, known for its deep black hue, is a widely used dye in various industries, particularly in textiles and leather. This article focuses on the importance of the Material Safety Data Sheet (MSDS) for sulphur black, outlining its safety measures, potential hazards, and manufacturer responsibilities.

What is Sulphur Black?

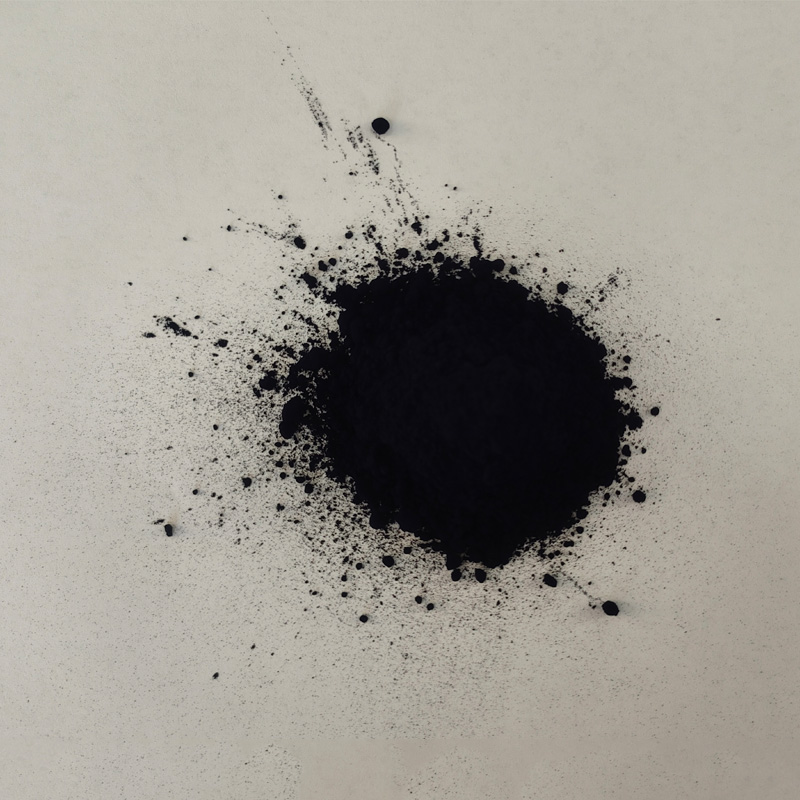

Sulphur black is a sulfur-based dye that appears as a stable black powder. It is primarily applied in dyeing textiles, especially cotton, due to its excellent color fastness and ability to withstand various washing conditions. Sulphur black is favored in industries for its affordability and effectiveness, making it a staple in the production of dark-colored fabrics.

Importance of MSDS

An MSDS, now commonly referred to as a Safety Data Sheet (SDS), is a crucial document that provides detailed information about a chemical substance. For sulphur black, the MSDS contains data regarding its properties, handling, storage, and emergency measures, ensuring safe usage for manufacturers, workers, and consumers.

Chemical Properties and Hazards

Sulphur black is generally considered to have low toxicity; however, certain safety precautions must be observed. According to the MSDS, inhalation of the fine powder can cause respiratory irritation, and prolonged skin contact may lead to irritation. Additionally, while not classified as a carcinogen, exposure to any chemical demands respect and precaution.

sulphur black msds manufacturer

The MSDS outlines necessary personal protective equipment (PPE) for those handling the substance, including gloves, goggles, and dust masks or respirators. Proper ventilation in workspaces is also emphasized to minimize inhalation risks.

Safe Handling and Storage

Manufacturers are responsible for ensuring that sulphur black is handled and stored correctly. The MSDS provides guidelines indicating that the substance should be kept in a dry, well-ventilated area away from incompatible materials such as strong oxidizers. It is essential to maintain containers tightly closed when not in use to prevent moisture absorption, which can compromise the dye’s effectiveness.

Emergency Measures

In the event of an accident, such as spills or exposure, the MSDS details the immediate steps to be taken. For spills, the area should be isolated, and appropriate clean-up procedures followed using suitable materials (e.g., vacuum with a HEPA filter). For exposure, the document outlines first aid measures, including rinsing eyes or skin with plenty of water and seeking medical attention if irritation persists.

Manufacturer Responsibilities

Manufacturers play a pivotal role in ensuring user safety. They must provide comprehensive and accessible MSDS documentation to all users and ensure that employees are trained in handling sulphur black. Regular updates to the MSDS are essential to reflect new findings or changes in regulations, reinforcing the commitment to safety.

Conclusion

As industries continue to rely on sulphur black for its coloring properties, the role of the MSDS cannot be understated. It serves as a vital resource for understanding the hazards associated with the substance and outlines the necessary precautions to ensure safe handling and usage. By adhering to the guidelines provided in the MSDS, manufacturers can foster a safer working environment and minimize risks associated with sulphur black, benefiting both workers and the overall industry.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.