Creating Unique Fabrics Using Custom Indigo Powder Dye Techniques for Vibrant Color Results

Creating Custom Dye with Indigo Powder A Journey into Color

Indigo, one of the oldest dyes known to humanity, has captivated artists and fabric enthusiasts alike for centuries. Derived primarily from the leaves of the indigo plant, this rich blue pigment has deep cultural significance across various societies. In recent years, there has been a resurgence of interest in natural dyes, particularly indigo powder, as artisans and hobbyists seek to create unique and custom colors for their textile projects. This article will explore the process of using indigo powder to create custom dye and the beauty of this remarkable hue.

Understanding Indigo Powder

Indigo powder is produced by fermenting and processing indigo leaves, resulting in a fine blue pigment that can be used for dyeing fabrics. The allure of indigo lies not only in its vibrant color but also in the rich history and tradition associated with its use. From the stunning textiles of West Africa to the iconic denim of American culture, indigo has a place in the hearts of many.

Preparing for Dyeing

Before diving into the dyeing process, it’s essential to gather all necessary materials. You will need indigo powder, a suitable dyeing medium, water, and fabric that you wish to dye. Natural fibers such as cotton, linen, and silk work best with indigo, as they allow the dye to penetrate and bond effectively.

The dyeing process begins with preparing the fabric. It should be washed to remove any finishes that may inhibit dye absorption. Some dyers also choose to pre-mordant their fabric with a mordant like alum, which helps fix the dye and enhance color vibrancy.

The Dyeing Process

custom dye with indigo powder

To create the dye bath, you’ll mix the indigo powder with water according to the instructions provided with your dye. The traditional method often involves creating a fermentation process that reduces the indigo into a soluble form. This can be accomplished by combining the powder with a reducing agent such as sodium hydrosulfite and an alkaline substance like soda ash.

Once the dye bath is prepared, immerse the fabric in the indigo solution. The fabric will initially appear green due to the chemical process but will gradually turn a deep blue as it oxidizes in the air. It’s a mesmerizing transformation—watching the fabric shift in color right before your eyes.

For custom shades, you can experiment with the length of time the fabric is submerged in the dye bath. Longer immersion results in darker hues, while shorter times yield lighter tones. Additionally, layering multiple dips can create beautiful depth in color, allowing you to achieve a range of shades from soft sky blue to deep navy.

Customizing with Techniques

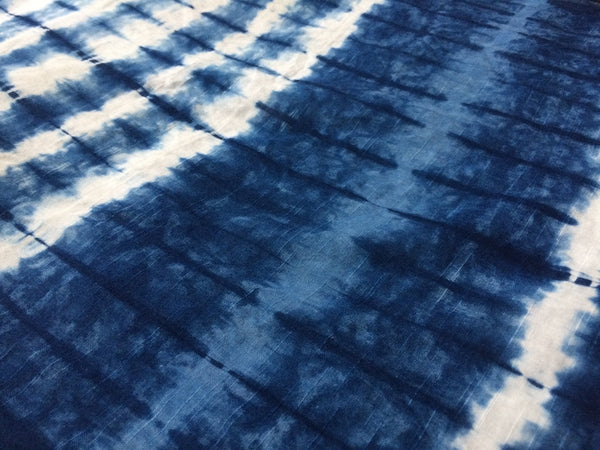

To add further creativity, you can incorporate various dyeing techniques such as tie-dyeing, shibori, or even block printing with resist materials. These techniques allow you to create intricate patterns and designs, turning your dyeing project into a unique work of art.

After reaching the desired shade, rinse the fabric in cold water to remove excess dye. It’s essential to let the fabric air dry away from direct sunlight, which can help preserve the vibrancy of the indigo.

Conclusion

Creating custom dye with indigo powder is not just a craft; it’s a connection to history and nature. By utilizing natural dyes, we honor traditional practices while embracing a sustainable approach to textile arts. Indigo offers endless possibilities, enabling creators to explore color, design, and personal expression. As you embark on your dyeing journey, take the time to appreciate the process and the beautiful hues that can emerge from this ancient practice. Let indigo inspire your creativity and enrich your fabric creations with its timeless beauty.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.