Exploring Unique Sources for Indigo Dye Production and Their Sustainable Potential

Custom Sources for Indigo Dye Exploring Traditional and Modern Techniques

Indigo dye, a deep blue pigment, has a rich history that dates back thousands of years. Known for its vibrant hue, it has been used across various cultures to tint textiles, creating iconic patterns and styles. In recent years, there has been a resurgence of interest in custom sources for indigo dye, driven by a combination of sustainable practices, artisanal craftsmanship, and the revival of traditional techniques. This article explores the diverse sources and methods of indigo dyeing, highlighting its cultural significance and modern applications.

Historical Context

The use of indigo dye can be traced back to ancient civilizations in Egypt, India, and China, where it was extracted from plants belonging to the Indigofera genus. Historically, indigo was one of the most sought-after dyes, often referred to as blue gold, due to its high value in trade. The dyeing process was labor-intensive, involving the fermentation of indigo leaves to convert them into a soluble form. This ancient technique, although time-consuming, created rich hues that were prized in textiles.

Sources of Indigo Dye

The two primary sources of indigo dye can be categorized into natural and synthetic production. Natural indigo is extracted from plants, while synthetic indigo is produced through chemical processes. Natural indigo is derived mainly from the Indigofera tinctoria plant, but other species, such as Polygonum tinctorium and Isatis tinctoria, are also sources. These plants contain indican, a compound that, when fermented, transforms into indigo dye.

Custom sourcing of natural indigo often involves small-scale farmers practicing sustainable agriculture. This grassroots approach not only supports local economies but also emphasizes the importance of biodiversity and traditional farming practices. Farmers cultivate indigo plants using organic methods, ensuring the purity of the dye, which is essential for artisans and crafters who seek high-quality materials for their work.

The Revival of Traditional Techniques

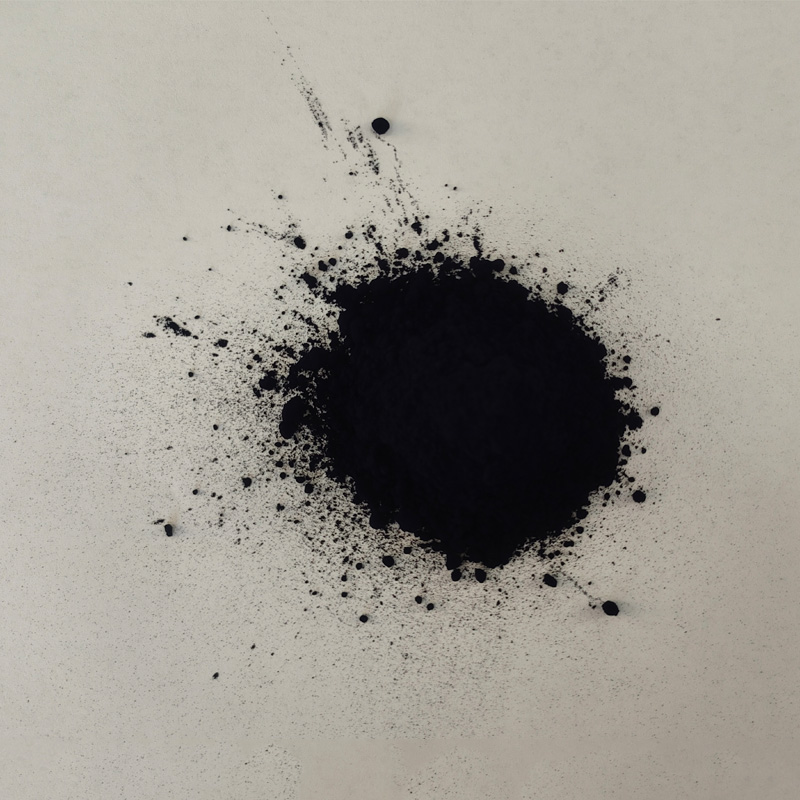

custom source for indigo dye

The revival of traditional indigo dyeing techniques has gained momentum in recent years as consumers increasingly seek authentic and sustainable products. Many artisans are turning to age-old methods of indigo dyeing, including shibori, a Japanese tie-dye technique, and resist dyeing practices from West African cultures. These methods not only yield beautifully patterned fabrics but also connect the maker to their cultural heritage.

Crafting custom indigo dye can involve various techniques that create unique patterns. For example, shibori employs folding, twisting, and binding the fabric before dyeing, resulting in intricate designs. This artisanal process is not just about aesthetics; it represents a deep understanding of materials and the transformation they undergo during dyeing.

Modern Applications

In the modern textile industry, there is a growing demand for sustainable dyes, leading many brands to explore natural indigo as an alternative to synthetic dyes, which are often harmful to the environment. Innovations in sourcing and production methods are also emerging. Some brands collaborate directly with farmers to create closed-loop systems, ensuring that sustainable practices are upheld throughout the supply chain, from plant cultivation to final product.

Moreover, the popularity of indigo dye extends beyond textiles. Home decor, accessories, and even art are being created using indigo, showcasing its versatility. This expansion into new domains encourages wider appreciation of the craft, fostering a sense of connection between consumers and the artisans who create these beautiful, hand-dyed pieces.

Conclusion

The exploration of custom sources for indigo dye signifies a convergence of tradition and innovation. As society becomes increasingly aware of sustainability, the revival of natural indigo—sourced from dedicated farmers and crafted using age-old techniques—offers a pathway to connect with cultural heritage and support ecological practices. By embracing these sources and methods, both artisans and consumers can participate in the ongoing narrative of indigo dye—a narrative rich with history, creativity, and a commitment to mindful production. In a world that often prioritizes mass production, the art of indigo dyeing serves as a reminder of the beauty and significance of handmade tradition.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.