custom sulphur dyes

Custom Sulphur Dyes Tailoring Colors for Unique Textile Needs

In today's vibrant world of textiles, color plays a crucial role in defining the appeal and marketability of fabrics. Among the various dyeing techniques available, custom sulphur dyes have emerged as a popular choice for manufacturers looking to achieve unique shades and effects. These dyes, known for their deep hues and excellent washfastness, offer a myriad of possibilities for both designers and textile producers.

Understanding Sulphur Dyes

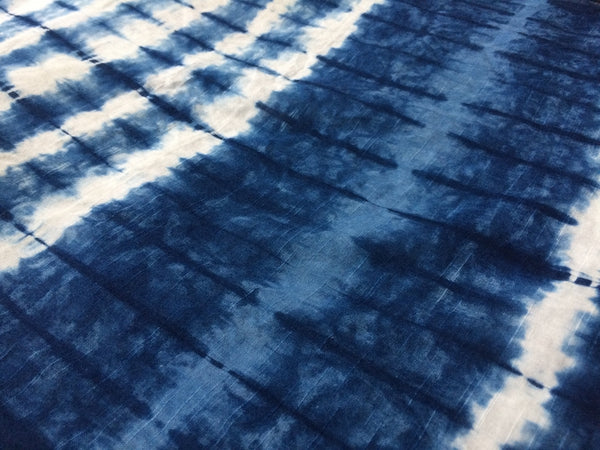

Sulphur dyes are a category of dyes that are primarily used on cotton and other cellulosic fibers. They are derived from thiophenes and are generally produced through a process that involves the sulfonation of organic compounds. One of the main advantages of sulphur dyes is their ability to achieve deep shades, especially in dark colors, making them especially popular for denim and workwear fabrics.

Traditionally, sulphur dyes were known for being limited to a specific range of colors. However, advancements in dyeing technology have opened up new avenues for customization. Now, manufacturers can create a wide array of colors, enabling them to meet specific market demands and consumer preferences.

The Importance of Customization

Customization in dyeing is not merely a trend; it is a necessity for modern textile industries. Brands seek to set themselves apart from the competition, and having unique color offerings can drastically enhance a product's appeal. Custom sulphur dyes provide the flexibility needed to create exclusive shades that resonate with brand identity and consumer desires.

Furthermore, the customization process allows for an exploration of various color combinations and effects. By adjusting the formulation of sulphur dyes, manufacturers can achieve different textures, fades, and finishes, adding an extra dimension to their textile offerings. The ability to create bespoke colors means that brands can align their products with specific seasonal collections or fashion trends.

Environmental Considerations

custom sulphur dyes

In recent years, the textile industry has faced increasing scrutiny regarding its environmental impact. As a result, many manufacturers are exploring eco-friendly dyeing practices. Fortunately, custom sulphur dyes can also align with sustainability goals. They often require less water and energy compared to some synthetic dyeing processes, and advancements in dyeing technology further contribute to reducing waste and emissions.

Furthermore, the durability of sulphur dyes tends to be higher, meaning that garments retain their color longer, consequently reducing the frequency of washing and the associated environmental footprints. By opting for custom sulphur dyes, brands can not only differentiate themselves in the market but also demonstrate a commitment to environmentally responsible practices.

Application in Different Textiles

The versatility of custom sulphur dyes extends beyond just cotton. These dyes can also be applied to a range of textiles, including blends with synthetic fibers. As fashion trends increasingly incorporate blended fabrics, the ability to use sulphur dyes on different substrates opens the door for innovation in textile design.

In denim, for instance, custom sulphur dyes can create rich, complex hues that are vital for achieving the desired aesthetic in distressed or vintage wash effects. In activewear, these dyes can provide not only vibrant colors but also the necessary durability to withstand the rigors of physical activity.

Conclusion

The trend toward custom sulphur dyes signifies a shift in the textile industry towards more personalized and environmentally conscious practices. Whether for fashion, home textiles, or industrial applications, the requirement for unique color offerings will continue to drive demand for these versatile dyes.

As technology evolves, the potential for custom sulphur dyes expands, allowing manufacturers to push the boundaries of color while maintaining an eye toward sustainability. This combination of creativity and responsibility positions custom sulphur dyes as a vital element in the future of textile innovation, catering to both consumer desires and environmental stewardship. In an industry where differentiation is key, custom sulphur dyes provide an opportunity to enhance product offerings, satisfy market trends, and embrace a greener approach to dyeing. By leveraging the strengths of sulphur dyes, brands can create a lasting impact in the colorful world of textiles.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.