Dried Indigo Powder Production for Quality Dyeing Solutions and Eco-Friendly Fashion

The Journey of Dried Indigo Powder From Factory to Fabric

Indigo, a deep blue dye with a rich history, has been cherished across cultures for thousands of years. The dried indigo powder, produced in factories around the globe, plays a crucial role in the textile industry by providing one of the most sought-after colors for fabrics. This article explores the process of producing dried indigo powder, its applications, and the environmental considerations involved.

The Production Process

The journey of dried indigo powder begins with indigo plants, primarily Indigofera tinctoria, which thrive in tropical and subtropical climates. The leaves of these plants are harvested and subjected to a thorough fermentation process. This involves soaking the harvested leaves in water and allowing them to ferment, which helps convert the indican present in the leaves into indigo dye. This step is vital, as it initiates the release of the color molecules that will later form the powder.

After fermentation, the leaves are processed to extract the indigo. The liquid from the fermentation is allowed to oxidize, creating a blue sludge. Once the sludge is formed, it is filtered and subjected to drying. The result is a solid, concentrated indigo dye that resembles blue paste. This paste is then further dried, ground, and pulverized to create the fine, dry indigo powder that is widely used in various industries.

Applications of Dried Indigo Powder

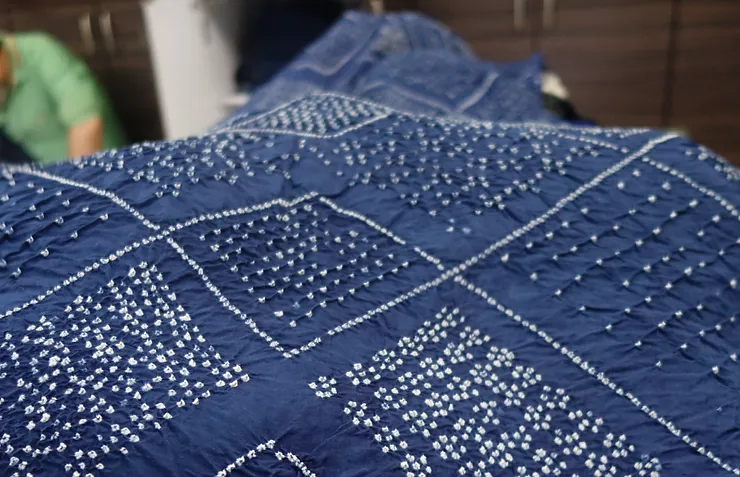

Dried indigo powder is predominantly utilized in the textile industry, particularly for dyeing cotton fabrics. Its vibrant blue color has made it a staple for denim production, giving birth to the classic blue jeans we know today. Unlike synthetic dyes, natural indigo has unique properties, including colorfastness and a beautiful fading effect that many consumers adore.

Beyond textiles, dried indigo powder has found its way into other industries as well. It is used in art as a dye for various mediums, including watercolor and fabric paints. Additionally, traditional medicine systems, such as Ayurveda, leverage indigo for its potential therapeutic properties. It has been used to treat various ailments, owing to its anti-inflammatory and antibacterial effects.

dried indigo powder factory

Environmental Considerations

While the production of dried indigo powder is a fascinating process that supports various industries, it is essential to consider the environmental impact. Traditional methods of growing indigo can be resource-intensive, requiring significant amounts of water and land. Furthermore, the fermentation process may produce waste materials that need to be managed carefully to avoid pollution.

However, as consumers become increasingly aware of environmental issues, many indigo factories are adopting sustainable practices. Some producers grow indigo organically, minimizing the use of chemical fertilizers and pesticides. Additionally, factories are incorporating waste management systems to reduce their ecological footprint, ensuring that by-products are either recycled or treated properly.

The rise of plant-based and natural dyes has also sparked interest in sustainable color sources. With the growing trend of eco-friendly fashion, the market for natural dyes, including dried indigo powder, is expanding. Brands are increasingly seeking out suppliers who prioritize sustainability, contributing to a more responsible production cycle.

Conclusion

The journey from indigo plant to dried indigo powder is a remarkable process that showcases nature's ability to provide vibrant colors used across various industries. The factories that produce this powder play a pivotal role in connecting consumers with the rich history and cultural significance of indigo dyeing. As the textile industry continues to evolve, incorporating sustainable practices is critical to ensuring that the production of dried indigo powder aligns with environmental stewardship and responsible consumption.

The future of dried indigo powder looks promising, fueled by a growing appreciation for natural dyes and sustainability in fashion. From the fields where the indigo plants grow to the hands of artisans and manufacturers, indigo continues to weave a story that is as colorful as the vibrant hue it produces. As we embrace this journey, we not only honor the past but also pave the way for a more sustainable and environmentally conscious future in textile production.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.