dye for indigo manufacturer

The Role of Dyes in Indigo Production A Focus on Manufacturers

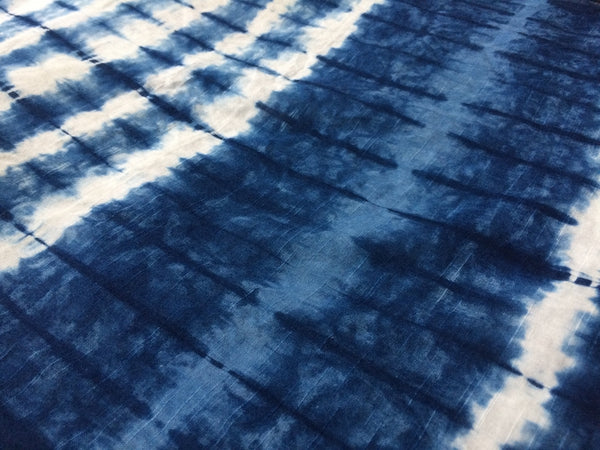

Indigo, a timeless dye with a rich history, has been cherished for centuries for its deep blue color. Its applications in textiles, art, and even modern initiatives for sustainable fashion have solidified its importance in various industries. However, one cannot overlook the pivotal role that dye manufacturers play in the indigo production process.

The Role of Dyes in Indigo Production A Focus on Manufacturers

Manufacturers have evolved to meet the increasing demand for indigo, leveraging advanced technology and sustainable practices. Today's dye manufacturers focus not only on the quality of the dye but also on minimizing environmental impact. Innovations such as waterless dyeing techniques and the use of eco-friendly chemicals are becoming more prevalent. This shift is particularly important as the fashion industry faces criticism for its ecological footprint.

dye for indigo manufacturer

The dyeing process itself is intricate. Manufacturers utilize a variety of techniques, including rope dyeing, vat dyeing, and direct application. Each method has its unique attributes, catering to different fabric types and desired outcomes. For instance, rope dyeing allows for a gradient of color, while vat dyeing produces a uniform hue. In addition, the depth of the indigo color can be adjusted by the number of dips in the dye solution, providing a unique palette for textile designers.

Quality control is another critical aspect of dye manufacturing. Manufacturers must ensure that their dyebaths are consistent and free from impurities. This involves rigorous testing and adherence to industry standards. As a result, reputable dye manufacturers are known for their proficiency in delivering high-quality indigo that meets the specific requirements of textiles producers.

Moreover, transparency and ethical sourcing have become significant concerns for consumers. Today’s dye manufacturers are increasingly sharing their sourcing practices and production processes, allowing consumers to make informed decisions. By prioritizing sustainability and ethical practices, these manufacturers not only support the traditional craft of indigo dyeing but also pave the way for a more responsible future in fashion.

In conclusion, dye manufacturers hold a vital position in the indigo dye production landscape. By embracing technological advancements, sustainable practices, and quality control, they contribute significantly to the enduring appeal of indigo while addressing the modern challenges of the textile industry. As fashion continues to evolve, the partnership between dye manufacturers and artisans remains essential in creating the beautiful indigo-dyed fabrics cherished around the world.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.