dyes for blue jeans product

The Art and Science of Dyes for Blue Jeans

Introduction

Blue jeans are a timeless fashion staple, worn by millions across the globe. From their origins in the late 19th century to their undeniable presence in modern wardrobes, jeans have evolved in style, fit, and color. However, one of the most significant elements contributing to the allure of blue jeans is the dye used to achieve that iconic indigo hue. This article explores the various dyes employed in the production of blue jeans, the science behind the dyeing process, and the impact of dye choices on the fashion industry and sustainability.

The Historical Context of Indigo Dye

The story of blue jeans and indigo dye is deeply intertwined. Indigo dye has been used for centuries, with references dating back to ancient civilizations in India, Egypt, and China. The natural dye is derived from the leaves of the indigo plant and is known for its vibrant blue color. This historical dyeing technique laid the foundation for the denim industry as we know it today.

The Introduction of Synthetic Dyes

While natural indigo played a dominant role in the early years of denim production, the late 19th century saw the rise of synthetic dyes, which revolutionized the dyeing process. Synthetic indigo was developed in 1890 by German chemist Adolf von Baeyer, leading to a more cost-effective and consistent method of dyeing denim. Today, synthetic indigo dominates the market, offering a reliable alternative that maintains the rich color and desired fading characteristics of traditional denim.

The Dyeing Process From Yarn to Fabric

The dyeing process for blue jeans involves several key steps that are critical to achieving the desired hue and quality. It begins with the yarn; denim manufacturers often use ring-spun cotton for its durability and texture. The cotton yarn is then treated with indigo dye through various methods, including rope dyeing, slasher dyeing, and garment dyeing.

1. Rope Dyeing This traditional method involves twisting cotton threads into ropes and submerging them in a dye bath. The fibers absorb the indigo dye, creating a deep blue color while allowing for a lighter core, which contributes to the unique fading patterns associated with denim.

dyes for blue jeans product

2. Slasher Dyeing In this method, the yarn is unwound from large packages and run through a dye bath, allowing for even coverage. This technique ensures a consistent color and is widely used in large-scale production.

3. Garment Dyeing This more recent method involves dyeing the finished garment itself, allowing for enhanced color versatility and the ability to create unique shades and finishes.

Innovations in Eco-Friendly Dyes

As sustainability becomes increasingly important in the fashion industry, the traditional dyeing processes have come under scrutiny due to their environmental impact. The use of synthetic indigo dyeing often involves significant water usage and creates wastewater with harmful chemicals. In response, many manufacturers are exploring alternative, eco-friendly dyeing methods.

Innovations in eco-friendly dyes include using natural sources of indigo and developing dyeing techniques that reduce water consumption and chemical use. For example, brands are beginning to explore plant-based indigo and low-impact dye processes that minimize environmental harm. The introduction of waterless dyeing technologies and digital printing is also gaining traction, allowing for reduced resource usage and waste.

The Future of Dyes in Denim Production

The future of dyes for blue jeans looks promising as technology advances and consumer demands shift towards sustainable options. Brands that prioritize eco-conscious practices are likely to gain favor with environmentally-minded consumers, who are increasingly seeking transparency in production. Innovations in dye chemistry and processes will continue to evolve, ensuring that the art of dyeing blue jeans remains relevant for generations to come.

Conclusion

The dyes used for blue jeans are more than just a means to achieve color; they are a fusion of art, science, and history. As the industry grapples with the challenges of sustainability, the evolution of dyeing methods will play a crucial role in shaping the future of denim fashion. From the traditional use of natural indigo to the rise of synthetic alternatives and the exploration of eco-friendly practices, the journey of dyes in blue jeans is a fascinating narrative that continues to unfold. Whether you prefer the classic indigo or a more modern hue, one thing remains clear the dyeing process is integral to the blue jeans that have become a symbol of style and durability worldwide.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

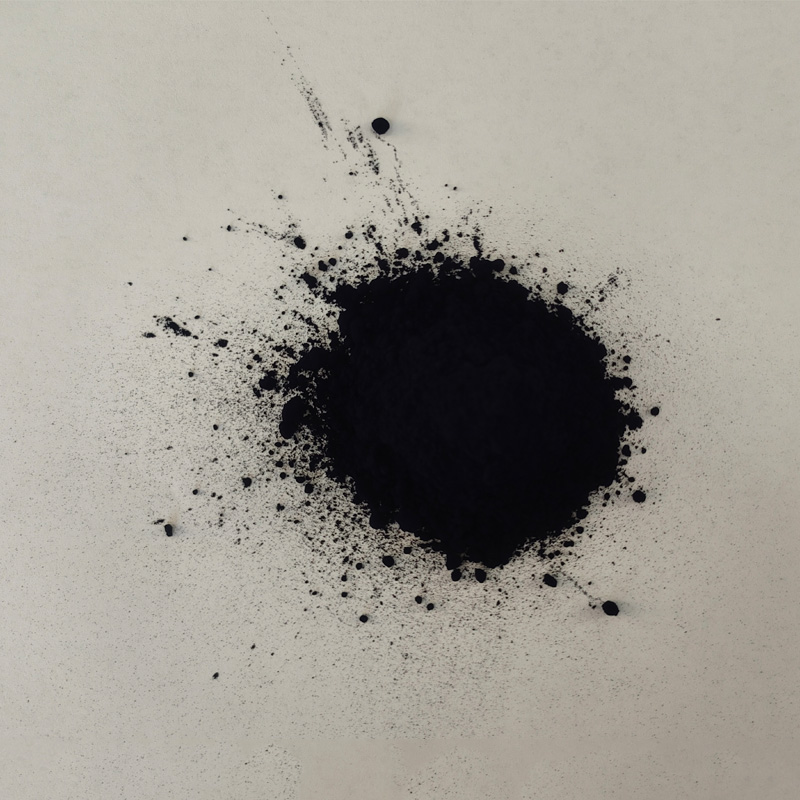

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.