Exploring the Traditional Art of Indigo Dyeing in China and Its Cultural Significance

The Process of Indigo Dyeing in China

Indigo dyeing has a millennia-old tradition in China that reflects not only aesthetic beauty but also rich cultural heritage. This ancient craft involves the use of the indigo plant, which produces a deep blue dye that has been cherished across various civilizations. In China, the process of making indigo dye is an intricate journey, blending natural resources, artistry, and community traditions.

Historical Context

The use of indigo dye in China dates back to as early as the Han Dynasty (206 BC – 220 AD), where it was highly valued for its vibrant color and colorfastness. Historically, indigo was derived from the leaves of the Indigofera plant. Its popularity skyrocketed during the Song (960–1279 AD) and Ming (1368–1644 AD) dynasties, as techniques for dyeing textiles were refined and the trade in indigo flourished. The color blue became synonymous with prosperity and status, often reserved for the garments of the elite.

Cultivation of Indigo

The first step in creating indigo dye is the cultivation of the Indigofera tinctoria plant. This perennial plant thrives in warm, sunny climates and requires well-drained soil. Farmers typically cultivate indigo in spring, and after several months, the plants are ready for harvest. Timing is crucial; leaves are gathered at peak maturity, as they contain the highest concentration of indican, the chemical precursor to indigo dye.

Harvesting and Processing

Once harvested, the indigo leaves must undergo a fermentation process to convert indican into indigo. The leaves are first soaked in water, preserved with a bit of lime, and allowed to ferment for several days. This fermentation process is essential as it transforms the indican in the leaves into a pigment that can bond with textiles.

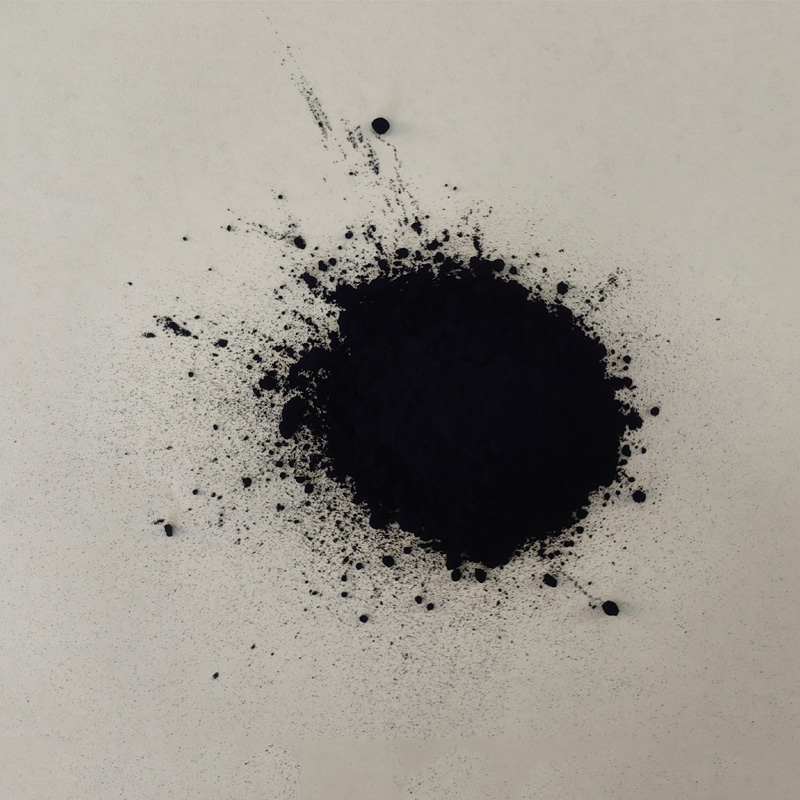

After fermentation, the mixture is stirred, producing a frothy layer on the surface. This froth is rich in indigo, which is then settled to the bottom. The indigo paste is collected, washed, and dried into solid cakes. This drying process not only enhances the color but also ensures the dye can be stored and transported.

china indigo making

The Dyeing Technique

The dyeing process itself is an art form. Fabrics intended for dyeing are first prepared, often by soaking them in a fixative solution to ensure the dye adheres effectively. The pieces of fabric are then submerged in a vat of the dissolved indigo paste. The unique aspect of indigo dyeing is the way it changes color. Initially, the fabric comes out greenish-yellow, but as it is exposed to air, it oxidizes and develops into a brilliant blue.

The depth of the blue can be manipulated by repeating this dyeing process. The fabric can be dipped several times to achieve darker shades, resulting in a color that ranges from delicate azure to deep navy.

Cultural Significance

Beyond its technical process, indigo dyeing carries significant cultural weight. Different regions in China have their own unique techniques and patterns, integrating indigo into various cultural expressions. For instance, the Dong people of Guizhou and the Bai people of Yunnan have long used indigo to create traditional textiles that tell stories and depict local lore.

The revival of traditional indigo dyeing techniques has also gained momentum as consumers today seek sustainable and environmentally friendly fashion choices. Natural indigo is free from synthetic chemicals, making it a popular choice among eco-conscious designers.

Conclusion

Indigo dyeing in China is more than a craft; it is a vivid tapestry of history, culture, and innovation. As the world embraces sustainable practices, the art of indigo dyeing not only preserves a rich heritage but also promises a vibrant future for textile artisans across generations. Whether seen in traditional garments or contemporary fashion, the ethereal beauty of indigo continues to captivate, united by the age-old craftsmanship behind its creation.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.