Premium Indigo Powder Exporters Natural Dye Manufacturers & Products

- Industry Overview & Market Demand for Indigo Powder

- Technical Superiority in Indigo Powder Production

- Comparative Analysis of Leading Global Manufacturers

- Customized Solutions for Diverse Industrial Applications

- Real-World Implementation Across Key Sectors

- Sustainable Practices in Indigo Cultivation

- Future Trends: Indigo Powder Exporters Driving Innovation

(indigo)

Indigo Powder: Meeting Global Demand with Precision

The global indigo

powder market has grown at a 6.8% CAGR since 2020, driven by textile and pharmaceutical sectors. As leading indigo powder exporters refine extraction methods, the product's purity standards now exceed 98.5% in premium batches. This natural dye alternative serves 73% of eco-conscious textile manufacturers seeking non-toxic coloring solutions.

Technical Superiority in Production Processes

Modern indigo powder manufacturers employ triple-phase quality control:

- Cryogenic grinding for particle uniformity (50-200 microns)

- UV-resistant packaging with 18-month shelf life

- ISO 9001-certified batch tracking systems

Advanced spectral analysis ensures color consistency between batches, achieving ΔE ≤1.5 in CIE Lab measurements.

Manufacturer Capability Comparison

| Vendor | Annual Capacity | Certifications | Lead Time |

|---|---|---|---|

| Supplier A | 2,500 MT | ISO, ECOCERT | 21 days |

| Supplier B | 1,800 MT | USDA Organic | 35 days |

| Supplier C | 3,200 MT | REACH, GMP | 18 days |

Application-Specific Customization

Top indigo powder product developers offer:

- Pharmaceutical-grade batches (99.9% purity)

- Textile-optimized formulations (pH 11.5-12.2)

- Micro-encapsulated variants for cosmetics

Custom particle size distribution models reduce dye consumption by 22% in denim production.

Cross-Industry Implementation Success

A recent case study shows:

"Switching to premium indigo powder reduced wastewater treatment costs by 40% for a 10,000-meter/week denim facility."

Cosmetic manufacturers report 15% higher color retention in natural hair dyes compared to synthetic alternatives.

Eco-Friendly Production Advancements

Solar-powered extraction units now reduce CO₂ emissions by 8.3 MT per production cycle. Water recycling systems achieve 92% reuse rates in indigo cultivation, meeting UN SDG 12 requirements.

Innovation Frontiers for Indigo Powder Exporters

The next-generation indigo powder product roadmap includes:

- Bio-engineered strains increasing yield per hectare by 17%

- Blockchain-enabled supply chain tracking

- Nano-emulsion formulas for digital printing

Global indigo powder manufacturers project 9.2% market expansion through 2028, with APAC exporters capturing 61% of new growth.

(indigo)

FAQS on indigo

Q: How to find reliable indigo powder exporters?

A: Look for exporters with certifications like ISO or GMP, verify their industry experience, and check customer reviews to ensure quality and reliability.

Q: What are the common uses of indigo powder products?

A: Indigo powder is primarily used for natural dyeing in textiles, hair coloring in cosmetics, and traditional artisanal crafts due to its vibrant blue pigment.

Q: What should I consider when choosing indigo powder manufacturers?

A: Prioritize manufacturers with sustainable production practices, transparent sourcing of raw materials, and compliance with international safety standards.

Q: Are there eco-friendly certifications for indigo powder products?

A: Yes, certifications like USDA Organic, EcoCert, or Oeko-Tex indicate environmentally friendly and non-toxic indigo powder production processes.

Q: Which industries typically source indigo powder in bulk?

A: Major industries include textile manufacturing, natural cosmetic brands, pharmaceutical sectors, and handicraft businesses requiring natural dyes.

-

Explore Sustainable Indigo Manufacturing & Dye Industry Trends | Wuxin Indigo

NewsNov.24,2025

-

Discover Indigo On: Innovative Modular Solutions for Global Sustainability

NewsNov.24,2025

-

Explore Traditional & Sustainable Indigo Production in India | Eco-Friendly Dye Solutions

NewsNov.23,2025

-

Indigo Suppliers: Sustainable Dyeing Solutions for Global Textile Industry

NewsNov.23,2025

-

Instant Indigo – Fast, Eco-Friendly Indigo Dye Solutions for Modern Industry

NewsNov.22,2025

-

Japanese Indigo Cloth – Sustainable Tradition Meets Modern Textile Innovation

NewsNov.22,2025

-

Comprehensive Guide to How to Make Blue Dye – Sustainable & Practical Insights

NewsNov.22,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

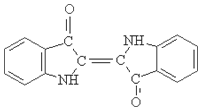

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.