Indigo dye is a popular OEM ink choice.

One significant advantage of OEM indigo ink dyeing is the ability to produce large quantities of dyed fabric with minimal variance

One significant advantage of OEM indigo ink dyeing is the ability to produce large quantities of dyed fabric with minimal variance

One significant advantage of OEM indigo ink dyeing is the ability to produce large quantities of dyed fabric with minimal variance

One significant advantage of OEM indigo ink dyeing is the ability to produce large quantities of dyed fabric with minimal variance oem indigo ink dye. This consistency is essential for branding and ensures that products maintain their aesthetic appeal across different production batches. Moreover, these specialized manufacturers often adhere to stringent environmental standards, using less water and chemicals compared to traditional dye houses.

Technological advancements also mean that OEM indigo dyeing can incorporate innovative techniques such as digital printing. This allows for intricate patterns and designs to be applied onto indigo-dyed fabrics, opening up a realm of possibilities for fashion designers and textile artists.

Despite these technological leaps, the allure of indigo remains rooted in its age-old traditions. The process still involves reducing the indigo pigment in a vat, creating a fermentation that reduces the dye to its soluble form before it can penetrate the fibers. The oxidation that occurs when exposed to air then fixes the color into the fabric, resulting in the iconic blue hue we associate with denim jeans and other classic indigo-dyed materials.

OEM indigo ink dyeing represents a blend of the old and the new, combining time-honored craftsmanship with modern manufacturing efficiency. As we move forward, it will be exciting to see how further innovations might enhance this process while preserving the integrity and beauty of this ancient dyeing technique.

oem indigo ink dye. This consistency is essential for branding and ensures that products maintain their aesthetic appeal across different production batches. Moreover, these specialized manufacturers often adhere to stringent environmental standards, using less water and chemicals compared to traditional dye houses.

Technological advancements also mean that OEM indigo dyeing can incorporate innovative techniques such as digital printing. This allows for intricate patterns and designs to be applied onto indigo-dyed fabrics, opening up a realm of possibilities for fashion designers and textile artists.

Despite these technological leaps, the allure of indigo remains rooted in its age-old traditions. The process still involves reducing the indigo pigment in a vat, creating a fermentation that reduces the dye to its soluble form before it can penetrate the fibers. The oxidation that occurs when exposed to air then fixes the color into the fabric, resulting in the iconic blue hue we associate with denim jeans and other classic indigo-dyed materials.

OEM indigo ink dyeing represents a blend of the old and the new, combining time-honored craftsmanship with modern manufacturing efficiency. As we move forward, it will be exciting to see how further innovations might enhance this process while preserving the integrity and beauty of this ancient dyeing technique. -

Innovating Bromo Indigo Excellence

NewsAug.23,2025

-

Pioneering Indigo Plant Dye Excellence

NewsAug.23,2025

-

Leading Sulphur Black Dyes Enterprise

NewsAug.23,2025

-

Sulphur Black Dyes Light Resistance

NewsAug.23,2025

-

Indigo Blue Granular Industrial Uses

NewsAug.23,2025

-

Bromo Indigo Synthetic Production Process

NewsAug.23,2025

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

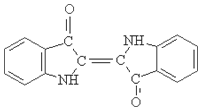

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

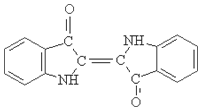

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.