Indigo Plant The Chinese OEM Perspective

This not only conserves water and reduces waste but also preserves the rich cultural heritage associated with indigo dyeing This not only conserves water and reduces waste but also preserves the rich cultural heritage associated with indigo dyeing

This not only conserves water and reduces waste but also preserves the rich cultural heritage associated with indigo dyeing This not only conserves water and reduces waste but also preserves the rich cultural heritage associated with indigo dyeing oem chinese indigo plant.

Furthermore, OEM production ensures consistency and quality control, two critical factors in today's global market. With strict adherence to environmental standards, these plants offer a blueprint for other natural materials looking to transition into the mainstream without sacrificing sustainability.

In conclusion, the integration of the oem chinese indigo plant into modern textile manufacturing represents a significant step towards a greener fashion industry. As consumers become more conscious of the environmental impact of their clothing choices, the demand for naturally dyed, sustainably produced fabrics will inevitably rise. The future of textiles may very well be blue, thanks to the enduring legacy of the Chinese indigo plant and the progressive spirit of OEM production methods.

oem chinese indigo plant.

Furthermore, OEM production ensures consistency and quality control, two critical factors in today's global market. With strict adherence to environmental standards, these plants offer a blueprint for other natural materials looking to transition into the mainstream without sacrificing sustainability.

In conclusion, the integration of the oem chinese indigo plant into modern textile manufacturing represents a significant step towards a greener fashion industry. As consumers become more conscious of the environmental impact of their clothing choices, the demand for naturally dyed, sustainably produced fabrics will inevitably rise. The future of textiles may very well be blue, thanks to the enduring legacy of the Chinese indigo plant and the progressive spirit of OEM production methods. -

Leading Light Indigo Color Company | Premium Dyes & Pigments

NewsAug.29,2025

-

Denim Indigo Dye Supports Sustainable Fashion

NewsAug.28,2025

-

Black Sulfur Elevates Material Durability

NewsAug.28,2025

-

The Alchemist's Indigo: A Forgotten Dye Of The Ancient World

NewsAug.28,2025

-

Sustainable Sulphur Black Dyeing: Eco-Friendly Methods For Textile Factories

NewsAug.28,2025

-

Sulfur Black Dyes: The Superior Choice For Industrial Applications

NewsAug.28,2025

-

Indigo Blue: History And Cultural Significance

NewsAug.28,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

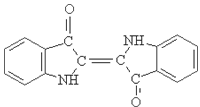

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

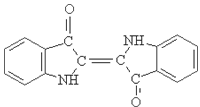

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.