indigo blue tie dye manufacturer

The Art and Science of Indigo Blue Tie Dye Manufacturing

Indigo blue tie dye, a vibrant and beloved textile technique, has seen a resurgence in popularity across the globe, combining artistic expression with traditional craftsmanship. The appeal of this age-old practice lies not just in the rich, deep hues of the fabric but also in the storytelling aspect that resonates through every piece. As a manufacturer of indigo blue tie dye products, understanding the history, process, and contemporary relevance of this craft is essential in delivering quality and authenticity.

A Brief History of Indigo Dye

Indigo dye (from the plant Indigofera tinctoria) has been used for thousands of years, tracing back to ancient civilizations in India, Egypt, and China. It became a significant commodity that impacted trade routes, with indigo being referred to as blue gold. The color indigo was once a symbol of wealth and prestige, often used by royalty and nobility. The plant-based dye was different from synthetic dyes that emerged in the 19th century, offering a unique depth and brilliance that has stood the test of time.

The Tie Dye Technique

Tie dye, a dyeing technique that involves tying fabric in various ways to create unique patterns, has roots in many cultures worldwide, including Japanese shibori and African adire. The crux of tie dye lies in its ability to transform simple fabric into works of art through simple yet effective manipulations.

The process typically involves folding, twisting, or crumpling the fabric and securing it with strings or rubber bands. The bound areas resist the dye, leaving behind beautiful patterns that reflect the maker's intent and imagination. When indigo dye is introduced, it permeates the unbound sections, yielding stunning contrasts and vibrant blues that are both eye-catching and timeless.

The Manufacturing Process

The manufacturing of indigo blue tie dye apparel involves several critical steps that require both artistry and precision. Here’s a breakdown of the process

indigo blue tie dye manufacturer

2. Preparing the Indigo Dye Bath Indigo dye requires a fermentation process to create a soluble form. This involves mixing indigo powder with a reducing agent and water, allowing the solution to ferment for several hours.

3. Tying and Shaping the Fabric Once the dye bath is prepared, artisans weave their magic by folding and tying the fabric. Each well-placed tie will create distinctive patterns that make every piece unique.

4. Dyeing The tied fabric is then submerged in the indigo dye bath. Depending on the desired depth of color, pieces may undergo multiple dips. The oxidation process turns the fabric from a greenish hue to a rich indigo blue upon exposure to air.

5. Rinsing and Drying After dyeing, the fabric is rinsed to remove excess dye, then dried in an open environment to maintain the quality of the colors.

6. Post-Treatment To ensure the longevity of the colors, a vinegar solution may be applied. This not only sets the dye but also enhances the fabric's overall resilience.

Modern Relevance and Sustainability

As consumers increasingly demand sustainable practices, indigo blue tie dye manufacturers are embracing eco-friendly methods. Traditional dyeing techniques often utilize natural indigo, which is biodegradable and less harmful than synthetic dyes. Manufacturers are also exploring organic fabrics and sustainable production processes to minimize their environmental footprint.

Furthermore, tie dye is not just a nostalgic fashion statement but an avenue for self-expression. Contemporary designers are reimagining this craft, blending traditional methods with modern aesthetics. The result is a fusion of culture and innovation, allowing every consumer to own a piece of art that resonates with their personal style.

Conclusion

The world of indigo blue tie dye manufacturing is a rich tapestry of history, artistry, and sustainability. As we celebrate this vibrant fabric technique, it is essential to appreciate both the heritage and the innovation that bring these stunning pieces to life. Whether it’s a simple shirt or a unique textile masterpiece, each indigo blue tie dye item tells a story beyond just its color, connecting us to centuries of tradition while adapting to the ethos of today.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

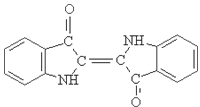

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.