indigo compound supplier

The Role of Indigo Compound Suppliers in Modern Industries

Indigo, a deep blue dye, has a rich history that dates back thousands of years. Known for its vivid color and cultural significance, indigo has been a staple in textile production and has made substantial contributions to various industries. The modern demand for indigo and its compounds has seen a dramatic shift, with suppliers playing a crucial role in ensuring that manufacturers everywhere have access to this essential ingredient.

The Historical Context

The use of indigo goes back to ancient civilizations, where it was derived from plants like Indigofera tinctoria. The dye was highly prized in cultures such as the Egyptians, Romans, and Indians, often reserved for the nobility and used in spiritual ceremonies. In recent times, however, synthetic indigo has become the mainstream choice due to its cost-effectiveness and consistency in color and quality.

The Rise of Indigo Compound Suppliers

Today, the role of indigo compound suppliers has transformed significantly. They serve as vital intermediaries in the supply chain, facilitating the connection between manufacturers and the chemical producers. These suppliers not only offer high-quality indigo compounds but also provide critical information about product safety, handling, and application, ensuring that businesses can utilize these materials effectively in their products.

One of the major trends in the industry is the increasing demand for eco-friendly and sustainable indigo. Conventional dyeing processes often involve harmful chemicals, leading to environmental pollution. Consequently, many suppliers are now offering natural and biodegradable indigo options, catering to the growing consumer demand for sustainable products. This shift not only focuses on environmental betterment but also aligns with the global trend of responsible manufacturing practices.

Innovations in Indigo Production

Indigo compound suppliers are not merely distributors; they are also pivotal in driving innovations in production methods. Advances in biotechnology, such as the use of genetically modified organisms (GMOs) for indigo production, have opened new avenues for creating efficient dyeing processes. Some companies are exploring fermentation methods, where specific bacteria can produce indigo in a controlled environment. This can significantly reduce water usage and lower the carbon footprint compared to traditional methods.

indigo compound supplier

In addition, suppliers are investing in research and development to enhance the performance of indigo compounds. For instance, innovations in solid formulations have made it easier for textile producers to use indigo without complicated dyeing procedures, ultimately reducing waste and increasing efficiency.

Challenges Faced by Indigo Compound Suppliers

While opportunities abound, indigo compound suppliers also face several challenges. Regulatory compliance is a critical issue, as suppliers must navigate a patchwork of environmental and safety regulations across different regions. Additionally, the volatility in raw material costs, influenced by factors like climate change and supply chain disruptions, can affect the pricing and availability of indigo compounds.

Moreover, the rise of digital technologies is changing the landscape of supplier-manufacturer interactions. Customers increasingly expect real-time data, efficient logistics, and seamless ordering processes. Suppliers that can adapt to these expectations while maintaining product quality will undoubtedly thrive in this competitive market.

Future Prospects for Indigo Compound Suppliers

Looking ahead, the future seems promising for indigo compound suppliers. As industries continue to seek alternatives to synthetic dyes due to environmental concerns, suppliers that invest in sustainable practices and innovative production methods will be better positioned to capture market share.

Furthermore, the textile industry is witnessing a resurgence of interest in artisanal and traditional dyeing techniques. This trend, combined with a modern edge of sustainability, may pave the way for a revival of natural indigo sources, adding value to suppliers who can bridge the gap between traditional practices and modern demands.

In conclusion, indigo compound suppliers are essential to the balance of tradition and innovation in the dyeing industry. They play a crucial role not only in supplying materials but also in fostering sustainable practices and driving the industry forward into a future that honors both heritage and environmental responsibility. As the world continues to evolve, these suppliers will remain at the forefront, ensuring that the legacy of indigo endures.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

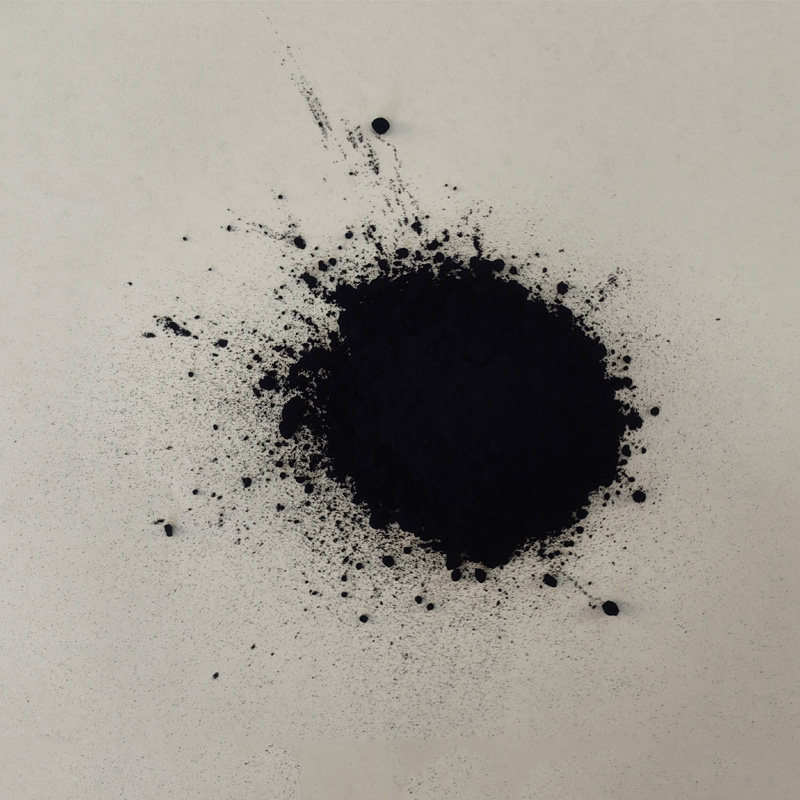

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.