indigo dark blue factories

The Enigmatic World of Indigo Dark Blue Factories

Indigo, a color that conjures images of the vast ocean and twilight skies, has a rich history intertwined with trade, culture, and sustainability. As we delve into the realm of dark blue factories that produce this iconic dye, we uncover not only the intricate processes of indigo production but also the cultural significance and ecological implications of this deeply rooted industry.

Historically, indigo dye has been revered across civilizations. From the ancient Egyptians who used it to adorn their textiles to the indigo plantations of colonial America, the color blue has held a profound significance. The process of extracting indigo dye is a labor-intensive journey, typically involving the fermentation of indigo plants, most commonly the Indigofera species. The leaves are harvested, soaked in water, and subjected to a fermentation process which converts the indigo glucoside in the leaves to indigo dye—an intricate dance of chemistry that has been perfected over centuries.

The Enigmatic World of Indigo Dark Blue Factories

However, the journey of indigo production is not without its challenges. The industrialization of indigo dyeing, particularly in the 20th century, introduced harmful synthetic alternatives. These synthetic dyes, while cheaper and easier to produce, come with significant environmental downsides. The growing awareness of these impacts has led to a resurgence of interest in natural dyes, prompting many factories to reinstate traditional practices. The revival of natural indigo not only supports sustainable practices but also empowers local communities by providing jobs and preserving cultural heritage.

indigo dark blue factories

In contemporary dark blue factories, sustainability is a core principle guiding production. Many of these facilities harness eco-friendly practices, such as rainwater harvesting and renewable energy sources. Farms around these factories often follow organic farming methods, eschewing harmful pesticides and fertilizers, thereby preserving biodiversity in surrounding ecosystems. This conscious shift toward sustainable indigo production reflects a broader trend in the fashion and textile industries, where consumers increasingly demand transparency and ethical practices.

Moreover, the impact of dark blue factories is not solely ecological; it extends into the realms of art and fashion. Indigo-dyed fabrics have gained popularity among designers and artisans worldwide. The deep blue color holds a versatility that can be utilized in various styles, from elegant gowns to modern streetwear. Artists often draw inspiration from the organic patterns created during the dyeing process, leading to unique textile designs that celebrate the marriage of tradition and modernity.

In addition to promoting sustainable practices, many indigo-producing factories are also adapting to modern market demands. This means embracing digital platforms for sales and promotion, enabling artisans to reach global audiences. Social media has become a powerful tool to showcase the beauty and craftsmanship of indigo-dyed products, connecting consumers directly with the creators and their narratives.

As we traverse the landscape of indigo production, it becomes evident that dark blue factories are more than mere production units; they are places of cultural significance and ecological responsibility. The story of indigo is one of resilience, creativity, and a continual balance between tradition and innovation. The deep, rich hues of indigo remind us of our shared history while prompting us to consider the future of our planet.

In conclusion, the dark blue factories dedicated to indigo production stand as a testament to human ingenuity and the importance of sustainability. As we embrace the beauty of indigo dyed textiles, let us also cherish the stories of those who produce them—stories that remind us of our global heritage and our commitment to a more sustainable future. The next time you don a piece of indigo fabric, remember the long journey it undertook, from the fertile fields to the colorful threads that weave our cultural tapestry.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

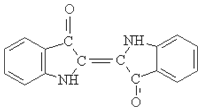

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.