indigo dyed cotton manufacturer

The Art and Craft of Indigo Dyed Cotton Manufacturing

Indigo dyed cotton has a rich history that dates back thousands of years, renowned for its deep blue hues and the intricate craftsmanship involved in its production. This traditional method has seen a resurgence in popularity, driven by a growing appreciation for sustainable fashion and artisanal techniques. As an indigo dyed cotton manufacturer, the journey begins with the careful selection of high-quality cotton, which serves as the foundation for this vibrant textile.

The indigo dyeing process is deeply rooted in cultural significance and embodies an ecological approach to textile production. The dye is derived from the leaves of the indigo plant, which undergo a fermentation process to extract the rich blue pigment. This natural dyeing method, as opposed to synthetic alternatives, promotes environmental sustainability and supports local agriculture. It is a practice that not only colors fabric but also connects artisans with their heritage and local ecosystems.

Once the cotton is sourced, it undergoes a meticulous preparation process. The fabric is usually pre-treated to ensure better absorption of the indigo dye. This can involve processes such as scouring and bleaching, where impurities are removed, and the fabric is softened. After preparation, the cotton is dipped into the indigo vat, which is maintained at a specific temperature to achieve the desired shade. The dyeing can take several dips, with each layer building upon the previous one, resulting in a fabric that boasts rich, deep colors.

indigo dyed cotton manufacturer

In addition to the dyeing process, manufacturers often embrace various techniques to create unique patterns and textures. Shibori, a traditional Japanese tie-dye technique, or batik-style wax resist methods can be employed to create intricate designs on the fabric. These artisanal approaches not only enhance the visual appeal of the cotton but also provide an avenue for designers to express creativity and individuality.

As consumer demand shifts towards more sustainable and ethically produced textiles, indigo dyed cotton stands out for its environmentally friendly properties and cultural significance. Manufacturers are not just producing fabric; they are preserving a craft that has been honed over generations. This dedication to quality and sustainability makes indigo dyed cotton a beloved choice among designers and consumers alike.

In conclusion, the art of indigo dyed cotton manufacturing is a splendid blend of tradition, sustainability, and creativity. As we embrace mindful consumption, the beauty and richness of indigo dyed textiles serve as a reminder of the importance of supporting artisanal practices in our modern world.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

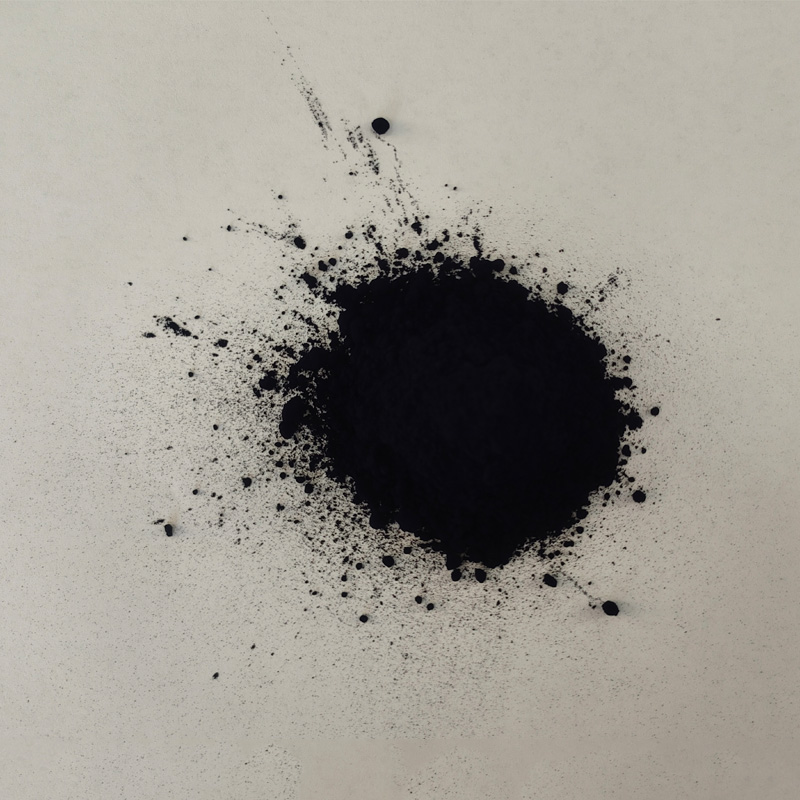

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.