indigo dye fabric factories

The Legacy and Innovation of Indigo Dye Fabric Factories

Indigo dyeing has long been one of the most revered arts in the textile industry, weaving a rich tapestry of history, culture, and innovation. The journey of indigo dye fabric factories is a testament to how a natural dye, steeped in tradition, has evolved with modern technology while still maintaining its artisanal roots.

Historical Significance

Indigo, derived from the plant Indigofera, has been used for thousands of years across various civilizations. Ancient Egyptians used it to dye their textiles, while in South Asia, it played a crucial role in the economy and culture. The process of indigo dyeing has been passed down through generations, often through family-run artisans who have mastered the techniques over years of practice. Factories began to emerge during the industrial revolution, scaling up production to meet the growing demand for this deep blue hue.

These factories became centers of innovation, where traditional methods were combined with new technology to improve efficiency without losing the quality of the dye. The art of indigo dyeing evolved, fostering a community of skilled artisans and workers united in their craft.

Modern-Day Indigo Dye Factories

Today, indigo dye fabric factories can be found around the world, from Asia to Africa and beyond

. These facilities vary in size and operation, from small batch artisans to large-scale manufacturers. Each factory plays a pivotal role in the local economy, providing jobs and supporting a network of farmers who cultivate indigo plants.Many modern indigo factories are embracing sustainable practices, recognizing the environmental impacts of dye production. The traditional method of dyeing involves a fermentation process that can be complex and resource-intensive. However, advancements in technology have allowed some factories to reduce water usage and eliminate harmful chemicals. Natural, organic indigo is being sought after by eco-conscious brands and consumers alike, leading to a resurgence of interest in artisanal and sustainable fabric production.

indigo dye fabric factories

Craftsmanship and Innovation

At the heart of any indigo dye factory is a commitment to craftsmanship. Skilled artisans oversee the dyeing processes, ensuring that the fabric maintains its quality. Each piece of fabric tells a unique story, shaped by the craftsmanship and the dyeing process. Different techniques such as tie-dyeing, shibori, and resist dyeing can create stunningly intricate patterns, each one a reflection of the culture that nurtured it.

In recent years, there has been a shift towards blending traditional techniques with contemporary fashion. Designers are experimenting with indigo dyed fabrics to create modern clothing lines that honor historical practices while appealing to current aesthetics. This fusion of old and new has brought indigo to the forefront of the fashion industry, highlighting its versatility and timeless appeal.

Cultural Impact and Education

Indigo dye fabric factories also serve as vital cultural hubs. Workshops and training programs engage the community, teaching younger generations about the significance of indigo dyeing and the skills involved. Such initiatives ensure that this age-old tradition is preserved and celebrated. By promoting awareness of the cultural heritage surrounding indigo, these factories help create a deeper appreciation for the craftsmanship involved in producing indigo dyed textiles.

Moreover, collaborations between local artisans and international designers encourage a cross-cultural exchange that enriches both parties. This exchange not only helps artisans gain exposure but also allows designers to incorporate unique elements into their collections, creating a beautiful bond between tradition and modernity.

Conclusion

In conclusion, indigo dye fabric factories are more than just production facilities; they are vital centers of culture, innovation, and sustainability. As they continue to blend traditional methods with modern practices, these factories not only honour a rich historical legacy but also pave the way for a sustainable future in the textile industry. The enduring allure of indigo ensures its place in the world of fashion and craftsmanship for generations to come, making it a true testament to the beauty of natural dyes and human artistry.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

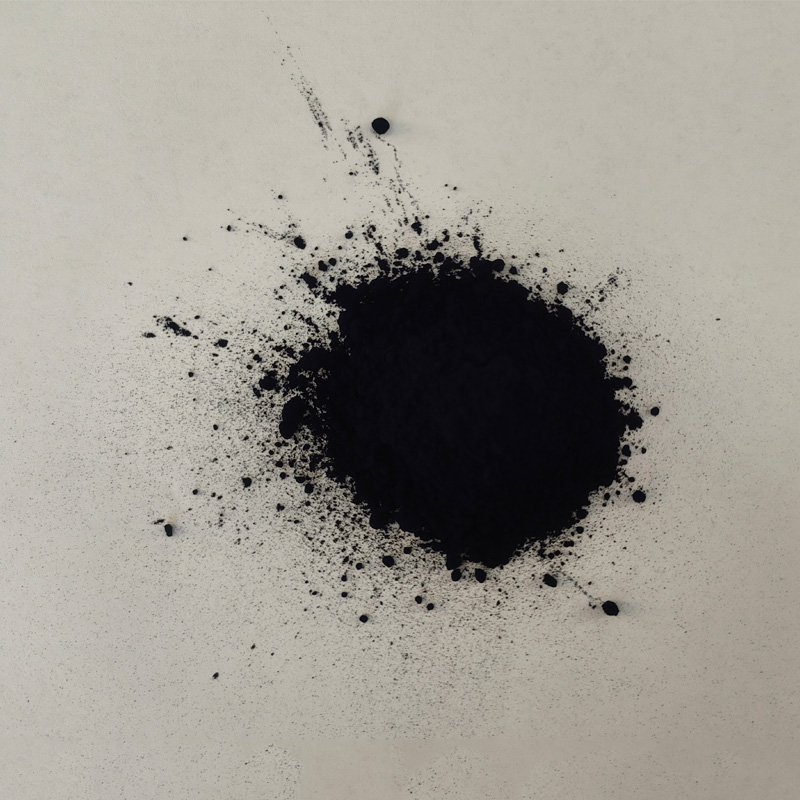

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.