Innovative Indigo Dyeing Machine for Efficient Textile Coloring Solutions

The Art and Science of Indigo Dyeing Machines

Indigo dyeing has a rich history that dates back thousands of years, revered for producing the deep blue hues that have adorned garments across cultures and continents. In recent years, the innovation of indigo dyeing machines has revolutionized the traditional craft, offering efficiency, precision, and sustainability. As industries pivot towards eco-friendly practices, understanding the technology behind indigo dyeing machines is essential for anyone involved in textiles.

The Process of Indigo Dyeing

Indigo dyeing involves several stages preparing the fabric, dyeing, and finishing. Traditionally, indigo was derived from plants of the Indigofera genus, requiring extensive processing. The leaves were fermented to extract the dye, which is not soluble in water but becomes reduced to a soluble form during dyeing. When exposed to air, this form oxidizes, creating the deep blue color that indigo is famous for.

However, as demand for sustainable options increases, the advent of indigo dyeing machines has made it easier for manufacturers to produce consistent results. These machines can automatedly handle each stage of the dyeing process while minimizing waste and maximizing efficiency.

Types of Indigo Dyeing Machines

1. Batch Dyeing Machines Ideal for small to medium-scale production, batch dyeing machines allow for precise control over dye concentration, temperature, and duration. This type of machine is perfect for artisanal manufacturers who want to maintain traditional practices while benefiting from modern technology.

2. Continuous Dyeing Machines Designed for large-scale operations, continuous dyeing machines are capable of processing vast amounts of fabric in one go. These machines utilize a continuous flow of fabric through a dye bath, ensuring even coloration and significantly reducing labor costs.

3. Eco-Friendly Dyeing Machines With a growing emphasis on sustainability, many companies are now investing in eco-friendly machines that use less water and energy. These innovations often include closed-loop systems, effectively minimizing water usage and preventing toxic runoff.

Advantages of Indigo Dyeing Machines

indigo dyeing machine product

The introduction of indigo dyeing machines presents several advantages over traditional dyeing methods

- Consistency Machines are designed to deliver uniform dye application, reducing variability and ensuring high-quality results for every batch.

- Efficiency Automation reduces labor costs and the time required to dye fabric, allowing for faster turnaround times, which is crucial in a fast-paced fashion industry.

- Sustainability Many modern machines are engineered with eco-friendly practices in mind, often featuring systems that recycle water and minimize chemical usage.

Challenges in Indigo Dyeing

Despite their advantages, indigo dyeing machines are not without challenges. One of the primary concerns is the initial investment cost. Setting up an efficient dyeing facility with the latest technology requires significant capital. Furthermore, operators must be trained adequately to manage and maintain these intricate machines, ensuring the dyeing process runs smoothly.

Additionally, while machines can mimic the traditional indigo dyeing process, some purists argue that the art's authenticity and craftsmanship are compromised. Balancing innovation with tradition remains a point of contention in the industry.

Conclusion

Indigo dyeing machines represent a pivotal shift in the textile industry, bringing the ancient art of indigo dyeing into the modern age. They offer unparalleled advantages in consistency, efficiency, and sustainability, responding to both consumer demand and environmental concerns. As the fashion industry continues to evolve, the integration of technology into traditional practices will likely play a crucial role in shaping the future of textiles. Whether one is a designer, manufacturer, or consumer, understanding the functionality and impact of indigo dyeing machines is essential in today’s rapidly changing landscape. The deep blues that have graced our clothes for centuries will undoubtedly continue to thrive, now with the support of innovative technology that honors the past while looking toward a sustainable future.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

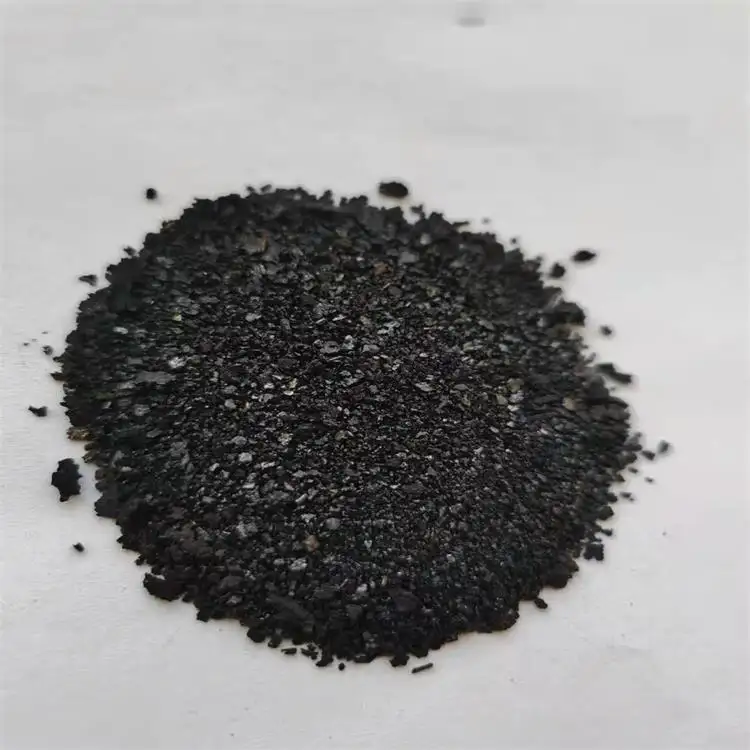

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.