Innovative Solutions for Indigo Fabric Production and Manufacturing Techniques

The Art of Indigo Making A Heritage Craft of Manufacturing

Indigo dye has a rich and storied history, deeply embedded in the cultural and economic practices of many societies. The process of indigo making, particularly through traditional methods, has been cherished for centuries, offering a glimpse into the craftsmanship, artistry, and sustainability aspects of dye production. Today, as we move towards sustainable fashion and eco-friendly products, the role of indigo manufacturers has become increasingly vital.

The Origins of Indigo

Indigo, known for its deep blue hue, is derived from plants belonging to the genus Indigofera. The cultivation of indigo dates back over 6,000 years, with evidence tracing its usage to ancient cultures in India, Egypt, and Mesopotamia. Historically, indigo was considered a luxury commodity, used to dye fabrics for the elite alongside being a significant export item.

The process of transforming indigo plants into dye involves a fascinating interplay of biology and chemistry. The primary component of the plant, indican, undergoes fermentation and oxidation, ultimately yielding the vibrant blue pigment. This intricate process is not only a testament to nature's creativity but also highlights the skill and knowledge of the indigo makers.

Traditional Indigo Dyeing Techniques

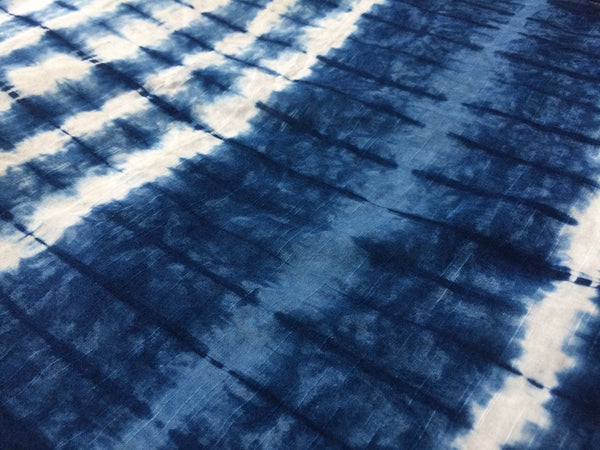

The art of indigo dyeing primarily involves two traditional techniques resist dyeing and direct dyeing. In resist dyeing, certain areas of the fabric are masked using materials like wax, stencils, or tie-dye techniques to create patterns. This method yields intricate designs, each narrating a story or symbol relevant to its culture of origin.

Direct dyeing, on the other hand, immerses the fabric directly into the indigo dye bath. The depth of color obtained usually depends on the duration of the fabric's immersion, a practice that showcases the expertise of the artisan. Many artisans today still stick to these time-honored methods, passing knowledge down through generations and ensuring that the craft remains alive.

indigo making manufacturer

The Rise of Sustainable Indigo Production

In recent years, the discussion about sustainability in fashion has grown, leading to a resurgence of interest in naturally derived products such as indigo. Unlike synthetic dyes, which can be polluting and harmful to the environment, natural indigo production is less harmful to ecosystems. Many manufacturers are now committed to using organic farming methods, allowing the regeneration of soil and reducing chemical runoff.

Moreover, the shift towards sustainable practices goes hand in hand with fair trade principles. Many indigo producers are small community-oriented businesses that prioritize ethical labor practices. By supporting these manufacturers, consumers contribute to the livelihoods of artisans who rely on their craft while promoting environmental stewardship.

The Modern Indigo Manufacturing Landscape

The modern landscape of indigo manufacturing is as diverse as the shades of blue it produces. From small-scale artisan workshops in rural areas to larger textile factories specializing in sustainable fabrics, the indigo industry has evolved significantly. Technological advancements have also played a role in the production process, making it more efficient while still preserving the essential qualities of traditional craftsmanship.

Fashion brands around the world are increasingly incorporating natural indigo in their collections, reflecting an appreciation for the craft and the story behind each dye lot. Educational initiatives are sprouting up, aiming to teach new generations about the art of indigo making, ensuring that this beautiful heritage craft continues to thrive.

Conclusion

The world of indigo making is a vibrant tapestry of tradition, artistry, and sustainability. As consumers, embracing products dyed with indigo not only adds a unique aesthetic to our wardrobes but also supports a legacy of craftsmanship. It reminds us of the interconnectedness between fashion, culture, and the environment, highlighting the importance of maintaining practices that honor both heritage and the planet. In a world increasingly focused on sustainability, indigo manufacturers stand at the forefront, exemplifying how traditional crafts can pave the way for a more responsible and beautiful future in the textile industry.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.