indigo making suppliers

The Role of Suppliers in Indigo Production

Indigo, a vibrant blue dye derived from the leaves of the indigo plant, has a rich history that dates back thousands of years. As a textile dye, it has been utilized across various cultures, particularly in Asia and Africa, where it has become an integral part of the fabric and dyeing industries. However, the production of indigo involves a complex network of suppliers, each playing a crucial role in ensuring that the final product meets quality standards and environmental regulations.

The Role of Suppliers in Indigo Production

Once harvested, the leaves undergo fermentation to extract the dye. This process requires expertise and care, as the quality of extraction directly affects the intensity and vibrancy of the final dye. Suppliers who have experience in indigo processing often collaborate with farmers to ensure that they receive high-quality leaves. This partnership promotes a reliable supply chain, where knowledge and best practices are shared, resulting in superior dye products.

indigo making suppliers

After the dye is extracted, it must be transported to textile manufacturers. This stage involves logistics management, ensuring that the indigo remains stable during transport. Suppliers with knowledge of proper packaging and transportation methods play a critical role in maintaining the quality of the dye. Moreover, they must comply with international regulations regarding chemical handling to prevent environmental hazards.

Finally, the textile manufacturers, who rely on these suppliers for high-quality indigo, utilize the dye in various applications, from denim jeans to exquisite fabrics. The collaboration between suppliers and manufacturers creates a seamless process that ensures the final products meet consumer demands for quality and sustainability.

In conclusion, the indigo supply chain is a testament to the interconnectedness of agriculture, processing, and manufacturing. A strong network of suppliers committed to sustainable practices is vital not only for the quality of the final product but also for the health of the planet. As consumers continue to seek eco-friendly options, the role of indigo-making suppliers will only grow in importance, shaping the future of the dye and textile industry.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

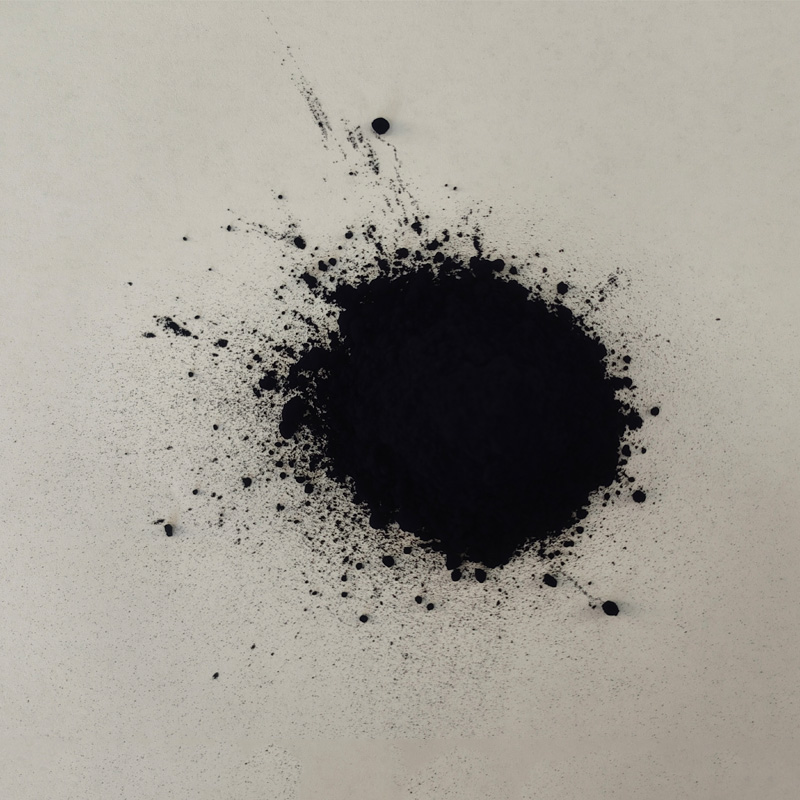

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.