Finding Reliable Suppliers for Indigo Products

The Importance of Indigo Suppliers in the Textile Industry

In the realm of textiles, color is one of the most impactful elements that can influence consumer preferences and market trends. Among various colors, indigo holds a special place, revered not just for its deep, rich hue but also for its historical significance. The sourcing of indigo dye has evolved significantly over the years, and the suppliers of indigo play a crucial role in shaping the industry today. This article delves into the importance of indigo suppliers and their contributions to the textile world.

Historical Context

Indigo dye has a storied history that dates back thousands of years. It was one of the first dyes used in human civilization, making a significant impact in various cultures around the globe. Historically, indigo was sourced from natural plants, notably the Indigofera genus. This natural dye was highly prized, leading to its trade along ancient routes, and it became synonymous with luxury and quality.

In recent times, while synthetic alternatives have been developed, the demand for natural indigo has surged once again. As consumers become more environmentally conscious, the appeal of sustainably sourced materials has gained traction. This shift has placed indigo suppliers at the forefront of the textile industry, wherein their choices can directly influence environmental sustainability and ecological responsibility.

Role of Indigo Suppliers

Indigo suppliers fulfill several key roles in the textile supply chain. Firstly, they cultivate and harvest indigo plants or produce synthetic indigo pigments, ensuring a steady supply of dye for manufacturers. The choice of sourcing—whether from natural or synthetic sources—depends significantly on market demand and consumer preferences.

Moreover, suppliers must maintain quality control over their products. Quality indigo can significantly affect the final product, influencing aspects such as colorfastness, hue, and overall fabric performance. Reliable suppliers invest in testing and quality measures to ensure their indigo meets industry standards.

Additionally, the suppliers are responsible for educating their clients about the dyeing process and best practices for application. This knowledge exchange is vital as it allows manufacturers to optimize their dyeing processes, resulting in better color outcomes and reducing waste.

indigo suppliers

Sustainable Practices

With the increasing awareness of environmental issues, there is a growing emphasis on sustainable practices in indigo production and sourcing. Suppliers who prioritize eco-friendly methods become the preferred partners for many brands seeking to minimize their environmental footprint.

Some suppliers have adopted organic farming techniques for harvesting natural indigo, eschewing harmful pesticides and chemicals. Others have focused on innovations in synthetic indigo production that reduce water usage and waste. By aligning with sustainable practices, these suppliers not only enhance their brand reputation but also contribute to the broader goal of minimizing the textile industry's impact on the environment.

Market Trends

The market for indigo is witnessing a revival, particularly with the rise of “slow fashion” and the rejection of fast fashion principles. Conscious consumers are increasingly seeking products that reflect their values, prompting brands to source responsibly. In this new landscape, indigo suppliers who can showcase their commitment to sustainability and ethical practices tend to flourish.

Additionally, the fashion industry is embracing the versatility of indigo in various applications beyond denim. From home textiles to ethical fashion collections, indigo is being reimagined in creative ways, driving innovative collaborations between suppliers, designers, and manufacturers.

Conclusion

Indigo suppliers are not merely conduits of dye; they are integral to the sustainable development of the textile industry. Their influence extends beyond the supply chain, helping to shape consumer attitudes toward color, sustainability, and ethical practices in fashion. As the emphasis on quality and environmental responsibility continues to grow, the role of indigo suppliers will become even more critical in determining the future of the textile industry. By sourcing wisely and partnering with conscientious suppliers, brands can ensure that their offerings resonate with the values of today’s consumers, paving the way for a more sustainable fashion landscape.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

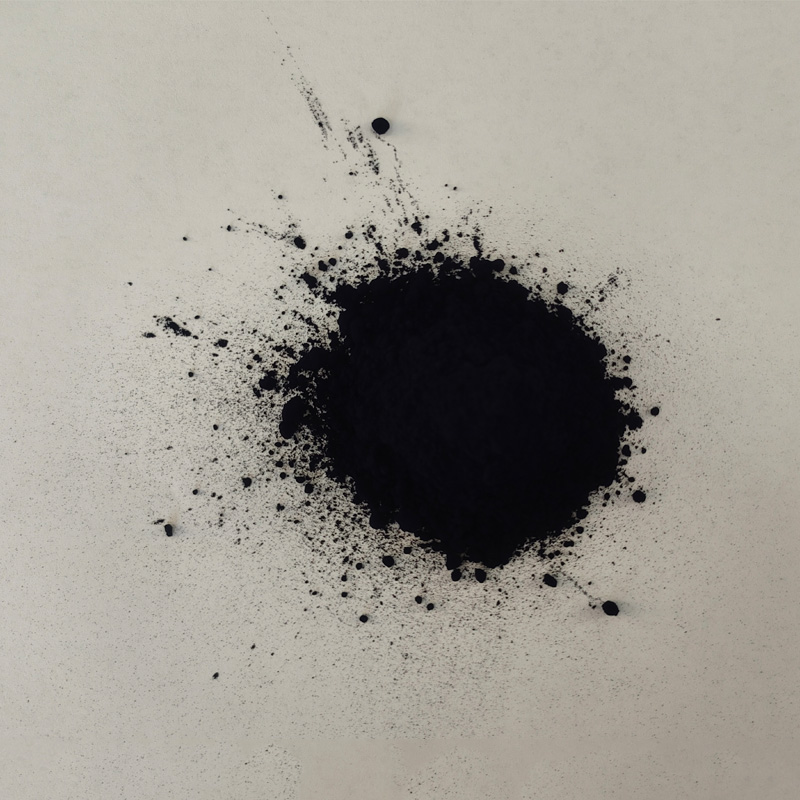

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.