indigo tie dye dress factory

The Art and Craft of Indigo Tie-Dye Dresses A Journey into the Factory

In the realm of fashion, few techniques possess the historical significance and aesthetic allure of tie-dye. Among the various methods of tie-dyeing, indigo tie-dye stands out with its unique depth of color and cultural heritage. This article takes you inside an indigo tie-dye dress factory, where the marriage of tradition and modernity creates a stunning array of garments that embody the essence of this ancient craft.

The Historical Significance of Indigo Dye

Indigo dye has been used for thousands of years, with its origins tracing back to ancient civilizations in India, Egypt, and China. The deep blue hue derived from the indigo plant was not only a sought-after color for textiles but also carried significant cultural meanings. In many societies, wearing indigo-dyed fabrics signified wealth and status. Today, the indigo dyeing process has evolved, yet the craftsmanship remains deeply rooted in tradition.

The Factory Setting

Stepping into an indigo tie-dye dress factory is like entering a vibrant tapestry of colors and craftsmanship. The air is thick with the scent of damp fabric and earthy indigo. Workers, often artisans with years of experience, engage in a delicate dance of tying, dyeing, and untying fabrics. The rhythmic motion is both meditative and efficient, resulting in beautiful, one-of-a-kind dresses.

The Process of Tie-Dyeing

The process of creating indigo tie-dye dresses is intricate and involves several stages. First, cotton or other natural fibers are chosen for their ability to absorb dye effectively. The fabric is then prepped and often washed to remove any impurities that may affect the dyeing process.

Next comes the tying stage. Artisans meticulously bind portions of the fabric with string or rubber bands. The patterns created during this stage will ultimately determine the design of the finished dress. Common patterns include spirals, stripes, and geometric shapes, each with its unique cultural significance.

indigo tie dye dress factory

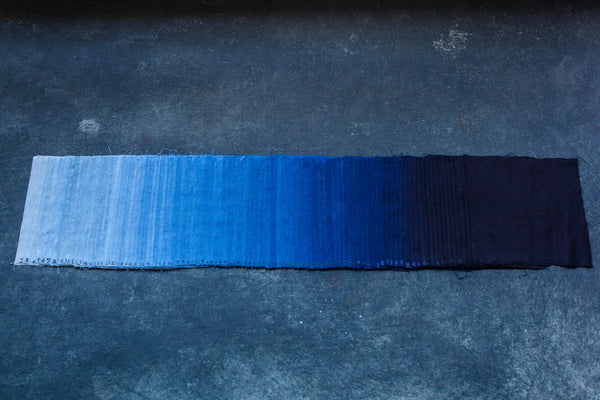

Once the fabric is tied, it is submerged in a vat of indigo dye. This step requires great care, as the dye can easily overwhelm the fabric if not properly managed. The indigo vat, a deep blue liquid with an intriguing chemical process, transforms the fabric as it reacts with oxygen. After the initial dip, the tied fabric is exposed to air, revealing the mesmerizing transformation from green to blue—a moment of pure magic.

After dyeing, the fabric is thoroughly rinsed to set the color, and the bindings are carefully removed, revealing the intricate patterns. This stage often brings excitement to the artisans, as the final design is unveiled, showcasing the unique artistry of each piece.

Crafting Indigo Tie-Dye Dresses

Once the fabric has dried, it is ready for the final transformation into a dress. Skilled seamstresses work with precision, cutting and sewing the fabric into various styles that reflect current trends while honoring traditional designs. From flowing maxi dresses to chic sundresses, the versatility of indigo tie-dye allows for a broad range of options.

Sustainability is an essential aspect of the production process. Many factories prioritize eco-friendly practices, sourcing natural dyes and employing sustainable methods. The use of organic cotton and minimal chemicals not only benefits the environment but also improves the quality of the final product.

A Cultural Celebration

Indigo tie-dye dresses are more than just garments; they are a celebration of culture and craftsmanship. Each dress tells a story—of the artisans, their techniques, and the cultural significance behind the patterns. Wearing an indigo tie-dye dress connects individuals to a rich history and a global movement towards sustainable fashion.

Conclusion

The journey through an indigo tie-dye dress factory reveals the beauty of a craft that has withstood the test of time. It marries age-old traditions with contemporary artistry, resulting in stunning garments that resonate with meaning and style. As the fashion industry continues to evolve, the indigo tie-dye dress remains a symbol of heritage, creativity, and sustainability—a timeless choice for the modern wardrobe.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.