industrial indigo pricelist

Understanding the Industrial Indigo Market Insights from the Current Price List

Indigo, a perennial favorite among dyers and textile manufacturers, is gaining momentum as sustainability becomes a priority in production processes. Particularly, the industrial indigo market is increasingly relevant as industries seek to balance traditional practices with contemporary demands for eco-friendly solutions. This article explores the nuances of the industrial indigo price list, its implications, and the factors influencing pricing trends.

Historical Context

Indigo has a rich history, dating back thousands of years to ancient civilizations. Once derived primarily from natural sources, such as the indigo plant, today’s industrial applications predominantly rely on synthetic processes. Synthetic indigo, often referred to as “indigo blue,” has enabled mass production and consistency in dyeing processes, revolutionizing the textile industry while also giving rise to significant environmental concerns. The transition from natural to synthetic was largely driven by the need for scalability and cost-efficiency.

Current Price Trends

An examination of the current industrial indigo price list reveals several key insights. Prices have fluctuated over the years due to various factors, including supply chain disruptions, raw material costs, and environmental regulations. As of the latest reports, the price per kilogram of indigo has seen an upward trend, influenced by rising demand from the textile sector, particularly in denim production, which consumes a considerable volume of this dye.

The current market price for industrial indigo typically ranges from $10 to $30 per kilogram, depending on the purity, form (powdered or liquid), and supplier. The variation in pricing also reflects the geographical regions where production occurs, with manufacturers in Asia, particularly India and China, often dominating the market share due to their established supply chains, cost advantages, and technological expertise.

Factors Influencing Prices

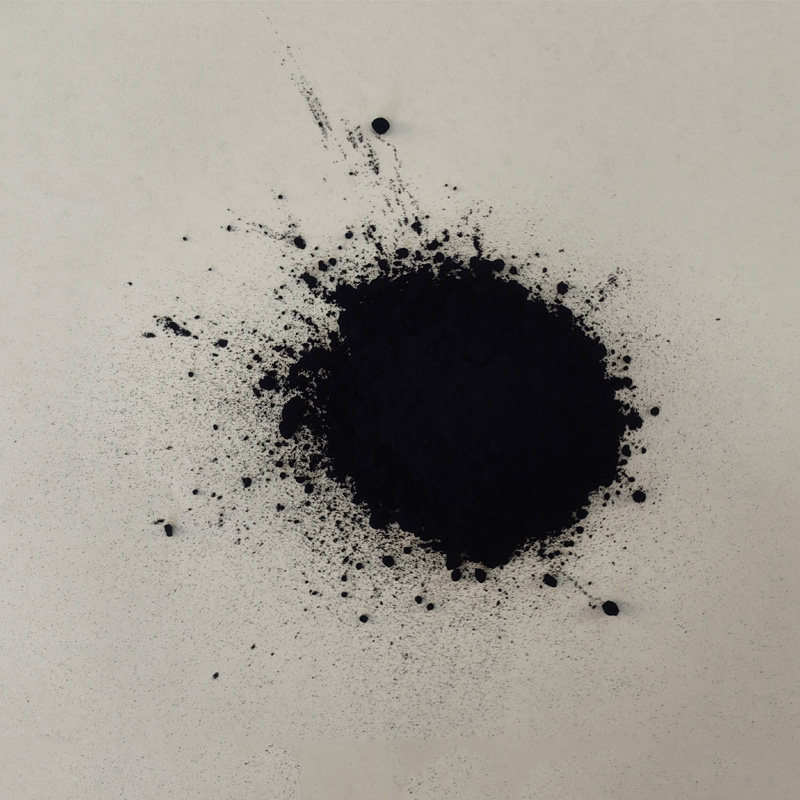

industrial indigo pricelist

Several key factors drive the pricing dynamics of industrial indigo.

1. Raw Material Costs The cost of precursor chemicals used in the synthesis of indigo, such as aniline, significantly impacts overall pricing. Volatility in the petrochemical market can lead to price fluctuations, which are passed down the supply chain.

2. Regulatory Environment As global awareness of environmental issues rises, stricter regulations concerning the chemical industry are being enforced. Compliance costs can contribute to increased prices, particularly for companies that prioritize sustainable practices.

3. Demand and Supply The demand for indigo, especially in sectors like denim, textiles, and arts, has been bolstered by fashion trends, including the resurgence of vintage styles and eco-conscious brands. Conversely, supply chain interruptions—including those caused by geopolitical tensions or natural disasters—can lead to scarcity and high prices.

4. Technological Advancements Innovations in the production of synthetic indigo are continually evolving. New methods that reduce waste and environmental impact may present initial cost challenges; however, they could lead to more stable prices over time if they become widely adopted.

Conclusion

As businesses navigate the complexities of production and pricing in the industrial indigo market, it is crucial to remain informed about market trends and factors affecting prices. The understanding of the current price list not only provides insights into operational budgeting for manufacturers but also highlights the interconnectivity of sustainability goals with economic realities. As the industry moves forward, embracing both technological advancements and sustainable practices will be essential in mitigating costs and ensuring consistent supply.

The industrial indigo price list serves as a vital tool for stakeholders in the textile industry, providing clarity amidst the ongoing shifts in global markets. By staying attuned to pricing dynamics and the underlying factors, businesses can make informed decisions that align with both profitability and sustainability goals, ensuring a resilient future in the ever-evolving textile landscape.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.