Leading Manufacturers of Instant Indigo for Textile Applications and Sustainable Practices

Instant Indigo Manufacturers A Deep Dive into the Modern Textile Industry

In the vibrant world of textiles, indigo dye has carved a niche for itself that stretches back thousands of years. Known for its rich blue hue, indigo has adorned fabrics across cultures and continents, from the luxurious robes of ancient Chinese dynasties to the casual denim that is ubiquitous today. In recent years, a new player has emerged in the indigo arena instant indigo manufacturers. This article explores the significance of these manufacturers in revolutionizing the textile industry, focusing on their methods, benefits, and the challenges they face.

The Evolution of Indigo Dyeing

Historically, indigo dye was derived from natural sources, primarily from plants such as Indigofera tinctoria. The traditional dyeing process was labor-intensive and time-consuming. However, with advancements in chemistry and technology, the development of synthetic indigo in the late 19th century revolutionized this industry. Today, instant indigo manufacturers have taken these advancements further, offering a new way to dye fabrics with efficiency and ease.

What is Instant Indigo?

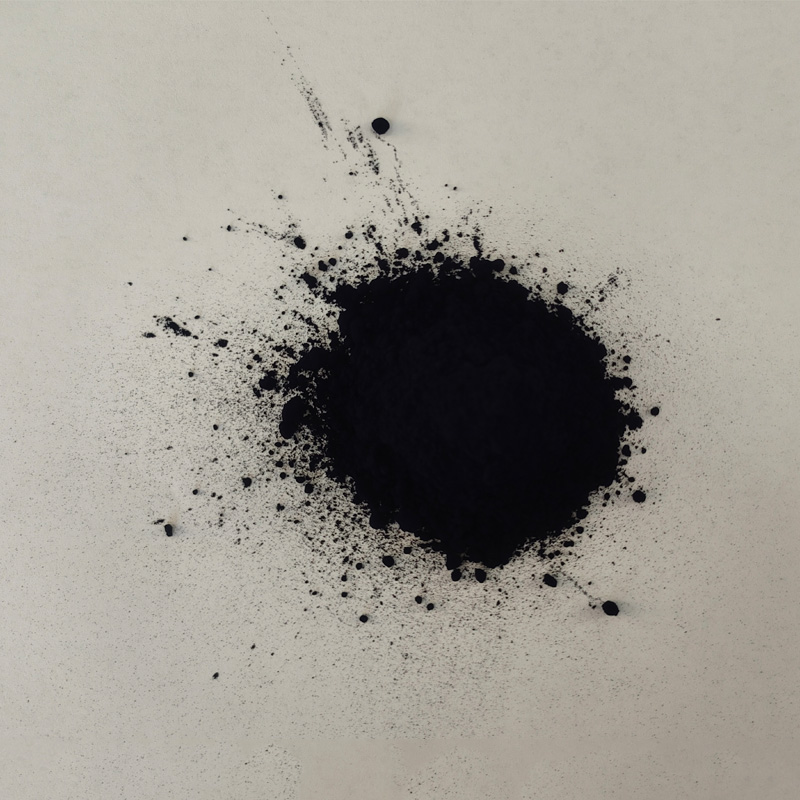

Instant indigo refers to pre-prepared indigo dye, often available in powdered form or as a ready-to-use solution. This innovation simplifies the dyeing process significantly. Instant indigo is designed to minimize the time, effort, and skill traditionally required to achieve the deep blue color that is synonymous with indigo. The ability to use instant indigo has democratized the dyeing process, allowing smaller manufacturers and hobbyists to create high-quality colored fabrics without extensive training.

Benefits of Instant Indigo

1. Efficiency One of the most significant advantages of instant indigo is its efficiency. Traditional indigo dyeing could take several days, involving multiple steps of fermentation and oxidation. Instant indigo, on the other hand, can drastically reduce this timeframe, allowing manufacturers to increase production rates and fulfill orders more quickly.

instant indigo manufacturers

2. Consistency Instant indigo provides a level of consistency that is difficult to achieve through natural dyeing methods. Each batch of instant blue retains its color quality, ensuring that the end product meets the same standards every time. This uniformity is crucial for manufacturers who supply to large retail chains and seek to meet quality expectations.

3. Reduced Waste The modern textile industry faces scrutiny regarding its environmental footprint. Instant indigo dye processes often generate less waste compared to traditional methods. Manufacturers can control the dye application more precisely, leading to lower water usage and reduced chemical runoff.

4. Versatility Instant indigo can be used on various fabrics, from cotton to synthetic blends. Its adaptability allows manufacturers to cater to diverse markets, whether producing high-end fashion items or affordable casual wear.

Challenges Faced by Instant Indigo Manufacturers

While instant indigo offers several benefits, it is not without its challenges. One major concern is the environmental implications of synthetic indigo production. Although instant indigo is more efficient, the base chemicals used in its creation can pose environmental risks if not managed responsibly. Manufacturers must balance efficiency with ecological sustainability, investing in cleaner production methods and responsible sourcing of raw materials.

Furthermore, there is a growing consumer demand for natural and organic textiles. While instant indigo appeals to mass production, some niche markets prioritize eco-friendly practices and natural dyes. Instant indigo manufacturers must navigate this complex landscape, ensuring that they are not left behind in a customer base increasingly inclined toward sustainability.

Conclusion

Instant indigo manufacturers represent a significant shift in the textile industry, providing innovative solutions that address traditional challenges. Their impact on efficiency, consistency, and waste reduction is noteworthy, making them vital players in modern manufacturing. However, as with any technological advancement, they face challenges that must be addressed, particularly in terms of environmental sustainability. As the industry continues to evolve, the relationship between instant indigo and sustainable practices will be pivotal in shaping the future of textiles. Ultimately, the blend of tradition and innovation will define the next chapter for indigo dyeing, ensuring its place in our wardrobes for years to come.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.