japan indigo manufacturers

The Legacy and Future of Indigo Manufacturing in Japan

Indigo, a deep blue dye extracted from the leaves of the indigo plant, has a long and rich history in Japan, where it holds cultural significance and economic value. Known as aizome in Japanese, indigo dyeing is an ancient craft that traces its roots back to the Edo period (1603-1868), during which it became a prominent industry throughout the country. This article delves into the unique practices of Japanese indigo manufacturers, exploring their cultural heritage, modern adaptations, and the challenges they face in a rapidly changing world.

The Cultural Heritage of Indigo Dyeing

Indigo dyeing in Japan is not merely a means of coloring fabric; it is an art form imbued with tradition. The intricate techniques used in aizome involve a meticulous process of harvesting and fermenting indigo leaves to create the dye. The result is a rich, deep blue that is both vibrant and enduring. Japanese artisans have perfected the craft over centuries, resulting in distinct regional styles, with notable centers in Tokushima, Okayama, and Kyoto.

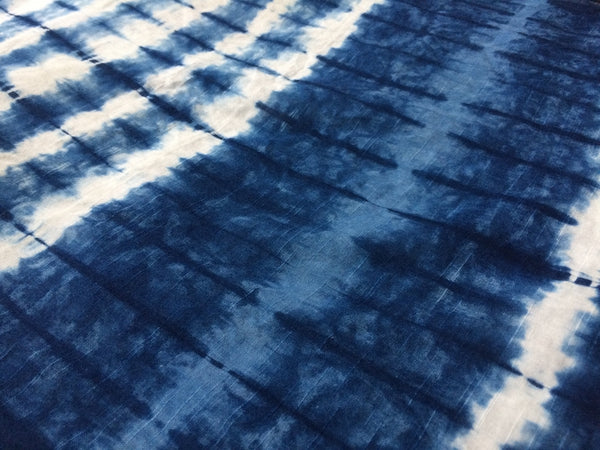

One of the most celebrated techniques is shibori, a method of resist dyeing that involves binding, stitching, or folding fabric to create intricate patterns. These unique designs celebrate the beauty of imperfection, highlighting the craftsmanship and artistry inherent in the process. As indigo dyeing is closely tied to the identity of various Japanese communities, the craftsmanship is often passed down through generations, strengthening cultural bonds and fostering a sense of pride.

Modern Adaptations and Global Influence

In recent years, the global demand for natural dyes has revived interest in traditional indigo manufacturing techniques. Japanese manufacturers have begun to embrace contemporary trends, marrying traditional methods with modern aesthetics. This fusion has led to the creation of a diverse range of products – from high-quality textiles for fashion to home décor items, all showcasing the beauty of natural dyes.

Japanese indigo manufacturers are also harnessing technology to improve their production processes while preserving traditional practices. Innovations in plant cultivation, dye extraction, and textile treatment have made it easier to meet the needs of a global market. Moreover, many artisans are collaborating with designers and brands to create unique pieces that appeal to both local and international buyers, helping to keep the tradition alive.

japan indigo manufacturers

Sustainability and Ethical Production

As concerns for environmental sustainability grow, Japanese indigo manufacturers are increasingly focused on sustainable practices. The use of natural indigo is heralded for its low environmental impact compared to synthetic dyes, which often involve harmful chemicals. Many manufacturers are adopting organic farming methods for their indigo plants, promoting biodiversity, and reducing pesticide use.

Furthermore, ethical production is becoming a cornerstone of the indigo industry in Japan. Artisans are paid fair wages for their craftsmanship, and there is a push towards transparency in the supply chain. Consumers are increasingly seeking products that reflect their values, and manufacturers are responding by promoting ethically sourced indigo textiles.

Challenges Facing the Industry

Despite the resurgence of interest in traditional indigo dyeing, the industry faces several challenges. The aging population in Japan means that fewer young artisans are entering the field, leading to a potential loss of traditional skills. The high costs associated with producing natural indigo and the intense labor required for dyeing processes can also pose barriers to growth and profitability.

Competition from synthetic dyes, which are cheaper and more accessible, threatens the market for natural indigo. To combat this, indigo manufacturers must continue to innovate and educate consumers about the value of artisanal practices and natural products.

Conclusion

The legacy of indigo manufacturing in Japan is a testament to the country's rich cultural heritage and craftsmanship. As the industry navigates the complexities of modernity, it embraces innovation while honoring tradition. By focusing on sustainability, ethical practices, and contemporary designs, Japanese indigo manufacturers are not only preserving their art form but also ensuring its relevance in today's market. The future of aizome is bright, reflecting a deep appreciation for the past while forging new pathways for future generations.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.